Vertical rotation hardening device of wind driven generator spindle

A technology for wind turbines and quenching devices, which is applied to quenching devices, heat treatment equipment, furnaces, etc., can solve the problems of high energy consumption, increased turning amount, and affecting the cooling speed and uniformity of the main shaft of the wind turbine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

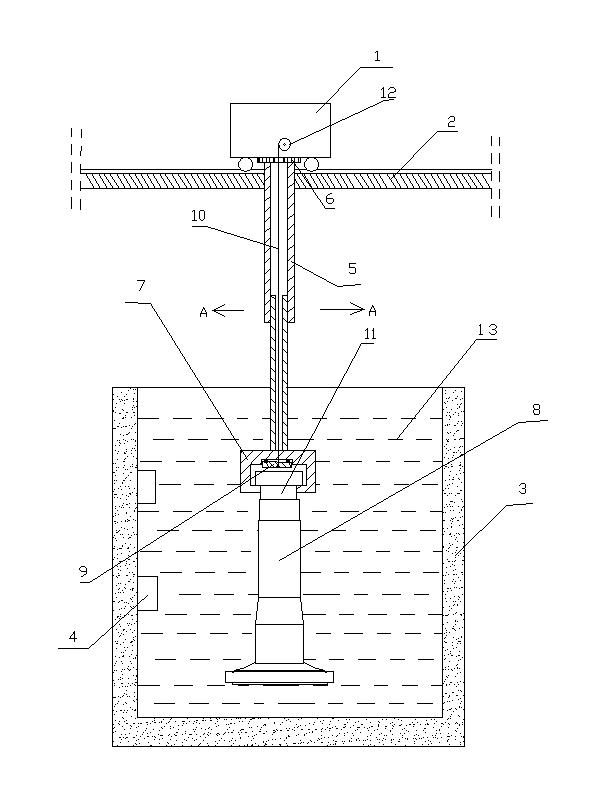

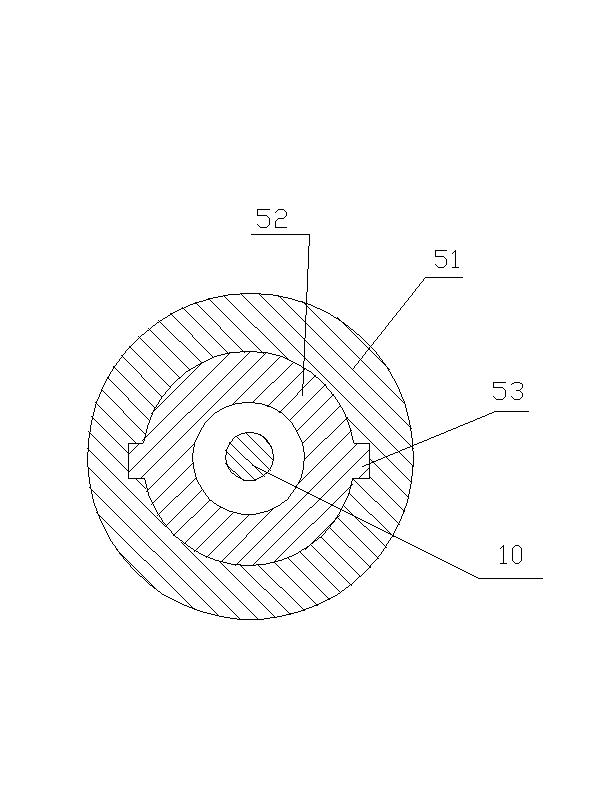

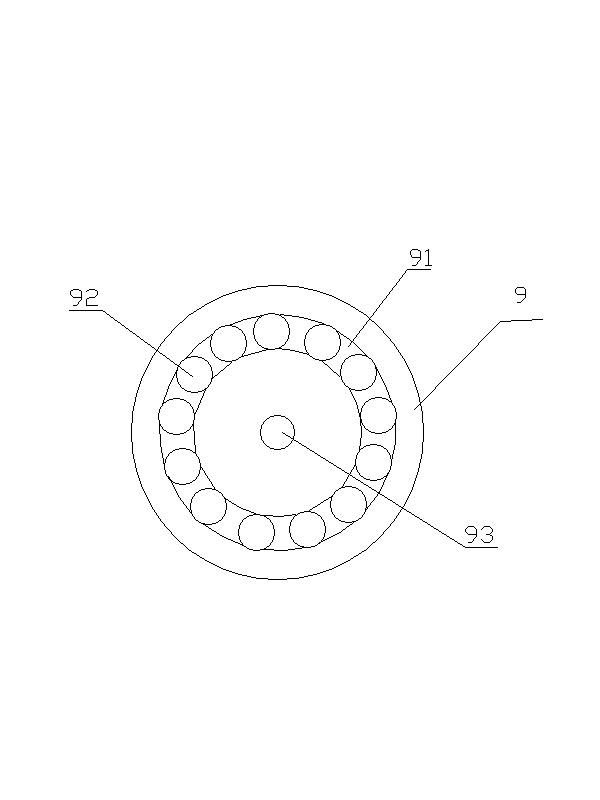

[0016] figure 1 , figure 2 , image 3 , Figure 4 Provided an embodiment, tried in our company in February, 2011. Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the vertical rotary quenching device for the main shaft of the wind power generator is composed of a vehicle 1, a vehicle track 2, a quenching oil tank 3 and a quenching oil circulation pump 4 that drives the flow of quenching oil. The driving track 2 travels, and the quenching oil circulation pump 4 is arranged on the side wall of one side of the quenching oil tank 3, and the quenching oil circulates in the quenching oil tank 3 through the quenching oil circulation pump 4, which is characterized in that: There is a rotating tube 5, the upper end of the rotating tube 5 is fixed on the rotating disc 6 driven by the motor on the crane 1, the lower end of the rotating tube 5 is welded and fixedly connected to the upper clamp 7, and the jaw of the lifting clamp 7 is stuck on the main shaft of the win...

Embodiment 2

[0023] The structure is the same as in Embodiment 1, but three quenching oil circulation pumps 4 are installed in the vertical direction, and the depth of the quenching oil 13 is twice the length of the main shaft 8 of the wind power generator.

[0024] Compared with the current method of horizontally lifting and lowering the main shaft of the wind power generator in the horizontal quenching oil tank, the quenching cooling time is shortened by 1 hour, and the power consumption is reduced by 500 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com