Feeding throwing jet for well digging

A shotcrete machine and material feeding technology, which is applied in shaft lining, shaft equipment, tunnel lining, etc., can solve the problems of poor working environment, low work efficiency, and high labor intensity, and achieve convenient installation and movement, improved work efficiency, and smooth operation. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in detail below in conjunction with accompanying drawing:

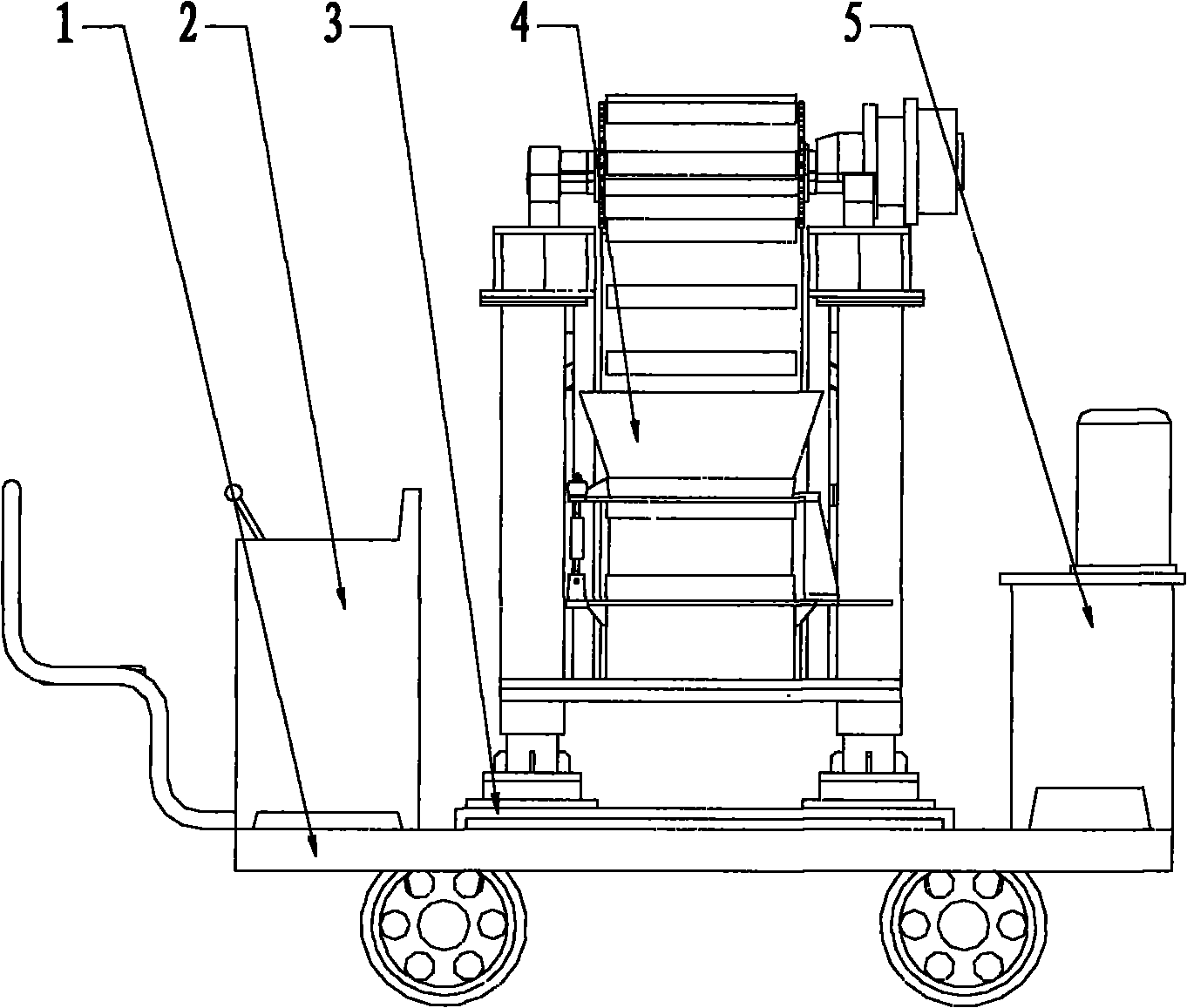

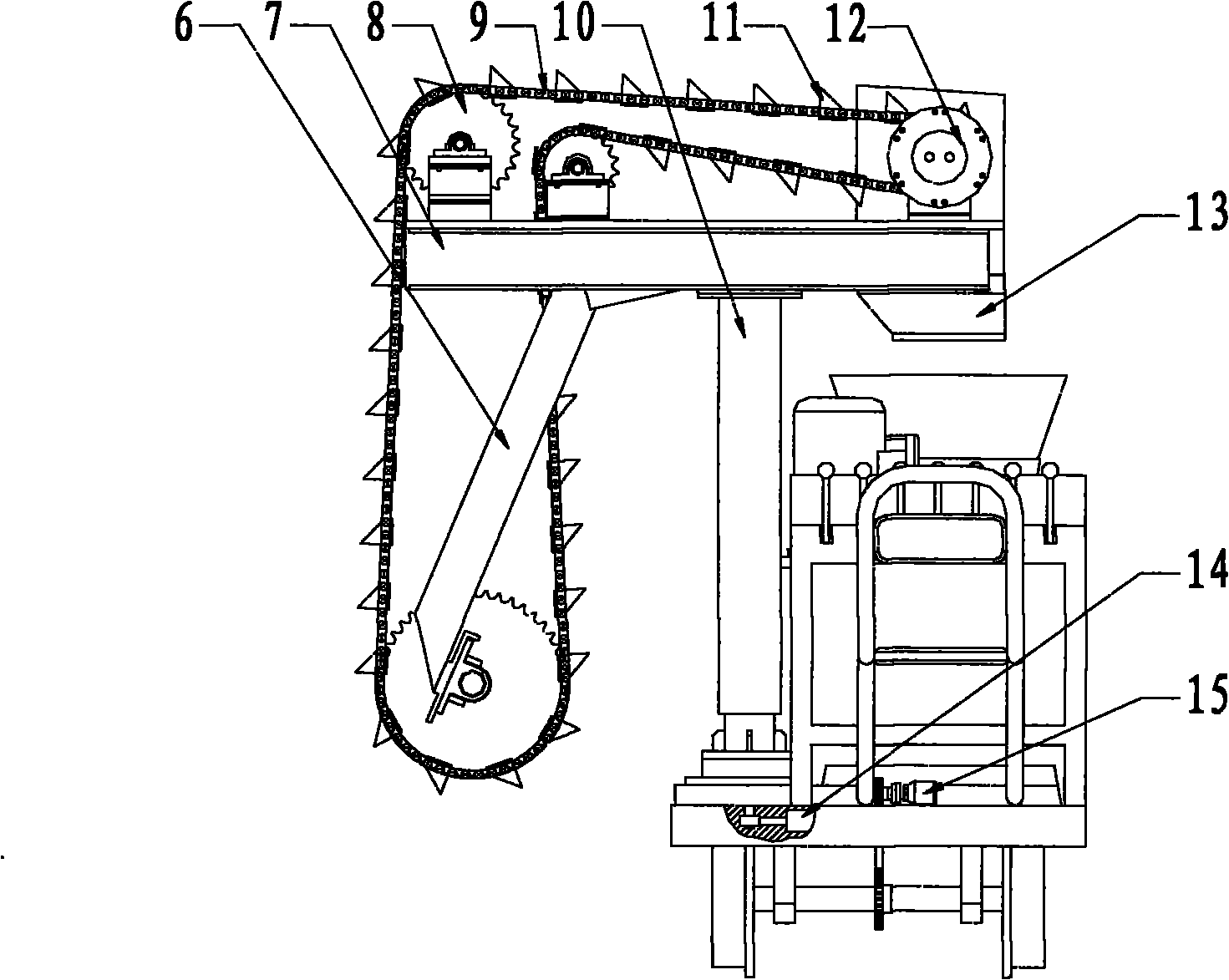

[0013] figure 1 , figure 2 The walking platform car 1 has a traveling mechanism 15, the operation console 2, the mobile platform 3, and the hydraulic pump station 5 are installed on the walking platform vehicle 1, the lifting column 10 is fixed on the mobile platform 3, and the spraying device 4 is fixed on the lifting column 10 , the crossbeam 7 is fixed on the top of the lifting column 10, the sprocket group 8 and the frame 6 are fixed on the crossbeam 7, the chain 9 forms a closed loop around the sprocket group 8, the bucket 11 is evenly distributed on the chain 9, and the feeding The hydraulic motor 12 is connected with the sprocket above the spraying device 4 , and the beam above the spraying device 4 is provided with a discharge port 13 .

[0014] When working, the lifting column raises the feeding device, pushes the mine car with material, and prepares for feeding. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com