Turbine fire resistant oil dual-pump parallel regulating system with bypass regeneration

An adjustment system and anti-fuel technology, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of degradation, anti-fuel regeneration and purification, and achieve the effect of removing solid impurities and acid removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

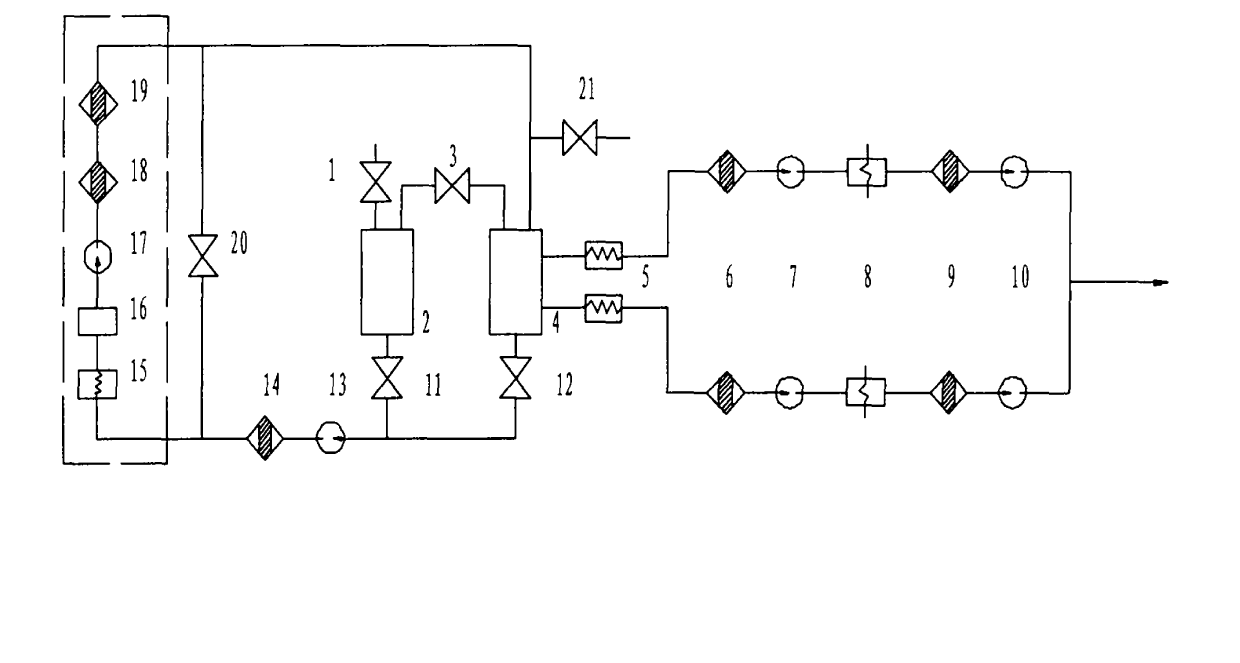

[0012] The anti-fuel oil in stock enters the oil storage tank (2) from the oil replenishment valve (1), and enters the main oil tank (4) through the oil tank connecting valve (3).

[0013] Fuel supply part: the booster pump (7) for anti-fuel in the main fuel tank (4) passes through the heating tank (5) and the filter (6), and is delivered to the main pump after being cooled by the cooler (8) and the filter (9) (10), the main pump sends the anti-fuel oil to the oil supply main pipe to the steam turbine.

[0014] Bypass regeneration part: If the anti-fuel oil in stock is unqualified, you can close the fuel tank connection valve (3) and the main fuel tank valve (12), open the fuel storage tank valve (11), and use the delivery pump (13) to pass through the filter (14) into the purifier. The main oil tank valve (12) can be opened when the degraded oil needs to be regenerated online. Dotted line part among Fig. 1 is purifier, and anti-fuel oil in purifier is heated through heater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com