A gas-phase deacidification and strengthening method for paper cultural relics

A paper cultural relic, gas phase technology, applied in the post-processing of waste paper, etc., can solve the problem of limited improvement, and achieve the effect of preventing paper deformation, avoiding shrinkage deformation, and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

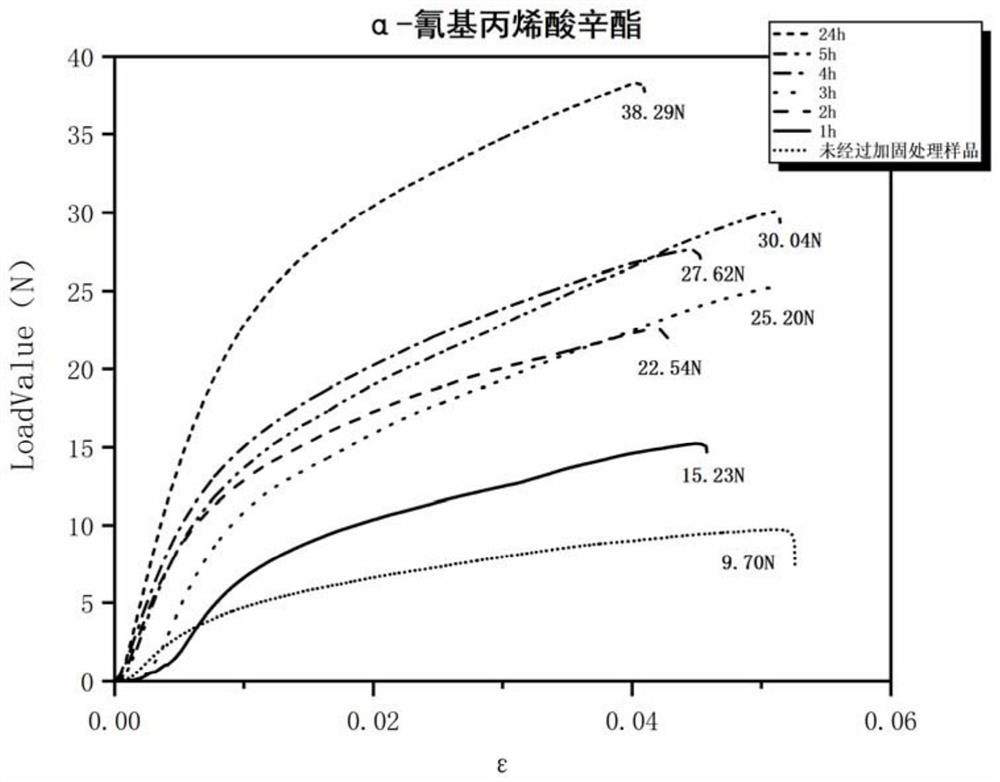

Embodiment 1

[0037] (1) The paper to be treated (taken from the book "Kingui Gangyao", the first edition in February 1959-the first printing, published by People's Health Publishing House) is brushed with a tartaric acid solution of pH=2.37 After that, put it in an oven to dry at 60°C for later use, so as to simulate the aging and acidification of paper;

[0038] (2) Lay the simulated acidified paper into a desiccator of appropriate size, and then put a plastic test tube with a capacity of about 25mL of ammonia into the desiccator; seal the desiccator and vacuumize it to maintain The pressure of the system is 0.01±0.005MPa, put the vacuumed dryer into the blast drying oven, set the temperature at 25°C (room temperature), and make the vaporized ammonia water contact and react with the paper for 30min;

[0039](3) After the reaction is over, the desiccator is taken out from the blast drying oven, and after the desiccator is connected to the atmosphere, the desiccator is opened to take out th...

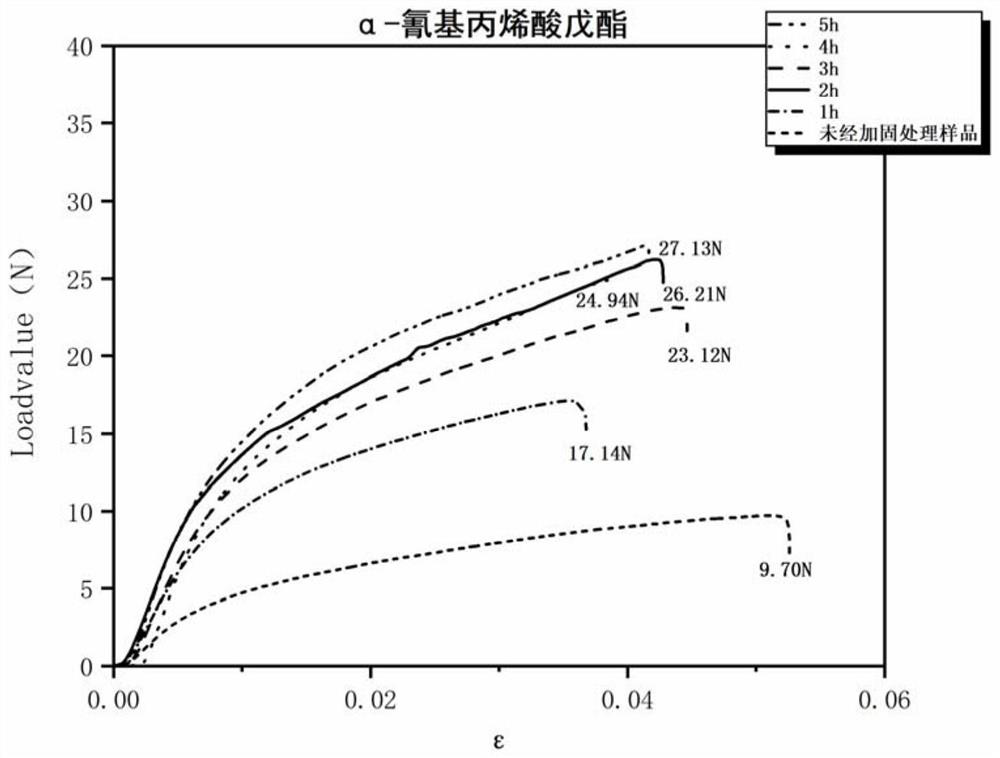

Embodiment 2

[0042] (1) The paper to be treated (taken from the book "Kingui Gangyao", the first edition in February 1959-the first printing, published by People's Health Publishing House) is brushed with a tartaric acid solution of pH=2.37 After that, put it in an oven to dry at 60°C for later use, so as to simulate the aging and acidification of paper;

[0043] (2) Lay the simulated acidified paper into a desiccator of appropriate size, and then put a plastic test tube with a capacity of about 25mL of ammonia into the desiccator; seal the desiccator and vacuumize it to maintain The pressure of the system is 0.01±0.005MPa, put the vacuumed dryer into the blast drying oven, set the temperature at 25°C (room temperature), and make the vaporized ammonia water contact and react with the paper for 30min;

[0044] (3) After the reaction is over, take the desiccator out of the blast drying oven, connect the desiccator to the atmosphere, open the desiccator and take out the plastic test tube cont...

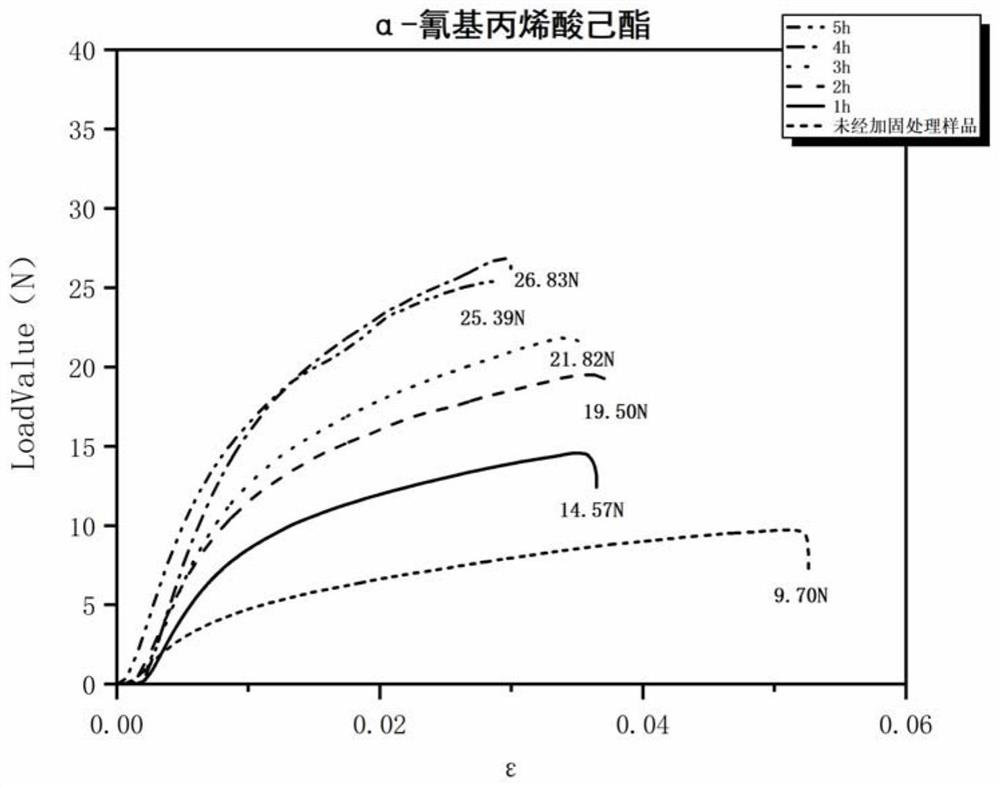

Embodiment 3

[0047] (1) The paper to be treated (taken from the book "Kingui Gangyao", the first edition in February 1959-the first printing, published by People's Health Publishing House) is brushed with a tartaric acid solution of pH=2.37 After that, put it in an oven to dry at 60°C for later use, so as to simulate the aging and acidification of paper;

[0048] (2) Lay the simulated acidified paper into a desiccator of appropriate size, and then put a plastic test tube with a capacity of about 25mL of ammonia into the desiccator; seal the desiccator and vacuumize it to maintain The pressure of the system is 0.01±0.005MPa, put the vacuumed dryer into the blast drying oven, set the temperature at 25°C (room temperature), and make the vaporized ammonia water contact and react with the paper for 30min;

[0049] (3) After the reaction is over, take the desiccator out of the blast drying oven, connect the desiccator to the atmosphere, open the desiccator and take out the plastic test tube cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com