Deep processing method of coal tar

A technology for deep processing and coal tar, applied in the direction of tar processing through distillation, separation methods, chemical instruments and methods, etc., can solve problems affecting equipment, affecting normal production, and reducing vacuum degree, so as to save maintenance time and cost, and guarantee The effect of continuous and stable operation and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

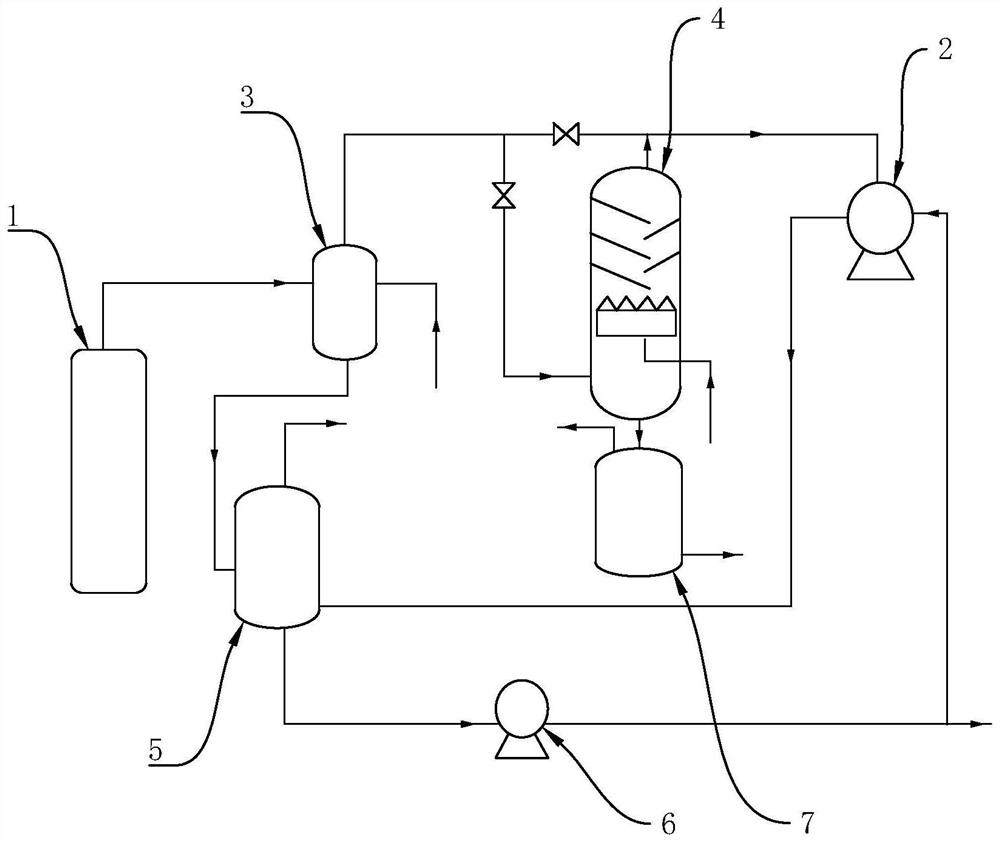

[0043] Embodiment 1 Technical process brief introduction of the present invention

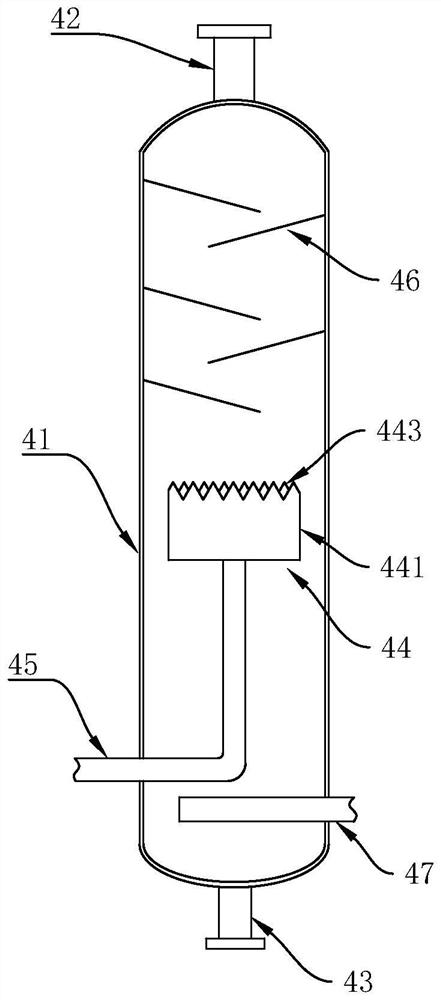

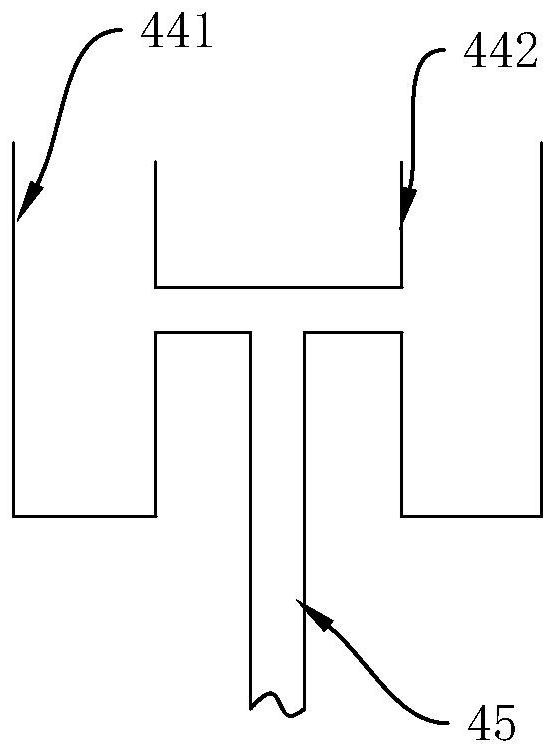

[0044] During the deep processing of coal tar, the soft bitumen extracted from the bottom of the atmospheric distillation tower is heated to 370°C by a decompression heating furnace and enters the decompression tower 1. Under the action of the vacuum system, a negative pressure is formed in the tower to extract the product. The oil gas at the top of tower 1 enters the vacuum tank 3 under the action of the vacuum pump 2, and the oil gas in the vacuum tank 3 is washed by the washing oil input from the outside of the vacuum tank 3, and the washed oil gas enters the acid removal reaction tower 4, and after washing The liquid in the liquid seal tank 5 is transported to the liquid seal tank 5, and the gas in the liquid seal tank 5 is transported to the tail gas system (not shown) for treatment and discharged, and the liquid in the liquid seal tank 5 is transported to the vacuum pump 2 for circulation ...

Embodiment 2

[0047] a. The soft bitumen in the decompression tower 1 is subjected to decompression treatment: the soft bitumen extracted from the atmospheric distillation tower extraction pump (P84004A / B) is sent to the decompression heating furnace to be heated to a temperature of 370°C at the bottom of the tower, and the pressure is controlled Under the action of the vacuum system, the temperature in the tower is 265°C, the control pressure is -20Kpa, and the heavy oil B is extracted from here, and the heavy oil B is pumped out through the heavy oil B waste pot (P84102A / B), and part of it is refluxed , part of which is extracted to the heavy oil tank of CB oil. The temperature of the upper part of the tower is 85°C, the control pressure is -35Kpa, and the heavy oil A is produced from here, which is pumped out by the heavy oil A extraction pump (P84103A / B) and passed through the heavy oil A waste pot and the heavy oil A2# cooler, part of which is refluxed and part of which is extracted Af...

Embodiment 3

[0052] a. The soft bitumen in the decompression tower 1 is subjected to decompression treatment: the soft bitumen extracted from the atmospheric distillation tower extraction pump (P84004A / B) is sent to the decompression heating furnace to be heated to a temperature of 390 ° C at the bottom of the tower, and the pressure is controlled Under the action of the vacuum system, the temperature in the tower is 252°C, the control pressure is -22Kpa, and the heavy oil B is extracted from here, and it is pumped out by the heavy oil B pump (P84102A / B) and passed through the heavy oil B waste pot, and part of it is refluxed , part of which is extracted to the heavy oil tank of CB oil. The temperature of the upper part of the tower is 80°C, the control pressure is -32Kpa, and the heavy oil A is produced from here, which is pumped out by the heavy oil A extraction pump (P84103A / B) and passed through the heavy oil A waste pot and the heavy oil A2# cooler, part of which is refluxed and part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com