Welding-free full-insertion-type LED (light-emitted diode) light source, method for installing same, and connection lamp holder matched with same for installing

An LED light source, welding-free technology, applied in the field of LED light source, to prevent glare, solve more expensive problems, and avoid accelerated light decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

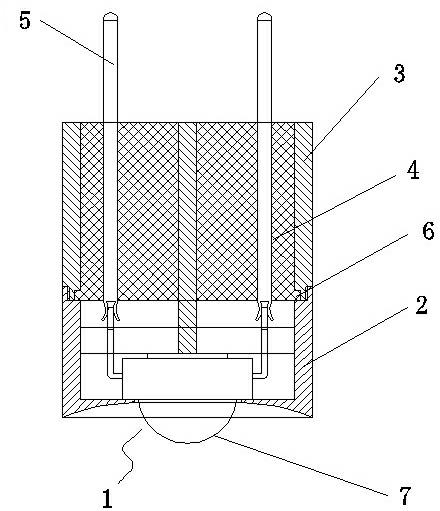

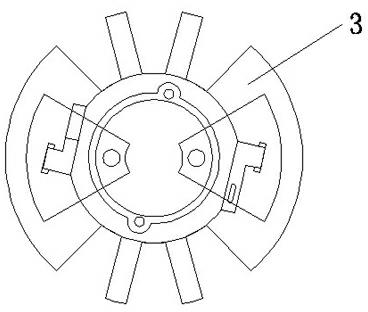

[0047] A solder-free fully pluggable LED light source described in Embodiment 1 of the present invention, such as figure 1 , figure 2 As shown, it consists of a lamp bead 1, a lampshade 2 with a fixed ring for fixing the lamp bead, a heat sink 3 fixed with the lampshade of the fixed ring, and a pair of positive and negative lamp pins 5 connected with the lamp bead. Such as figure 1 , Figure 8 As shown, the lamp bead includes a semi-circular lamp bead lens 7, an LED chip arranged in the lamp bead lens, a fixed lamp holder 8 for fixing the lamp bead lens, and the lamp holder is led out with positive and negative pins 10 connected with the LED chip and the lamp holder The bottom is provided with an LED bracket 9 . The fixed lamp holder and the positive and negative pins of the LED are set in the lampshade of the fixed ring, the lamp bead lens protrudes outside the lampshade of the fixed ring, and the end face of the lampshade of the fixed ring protruding from the lamp bead l...

Embodiment 2

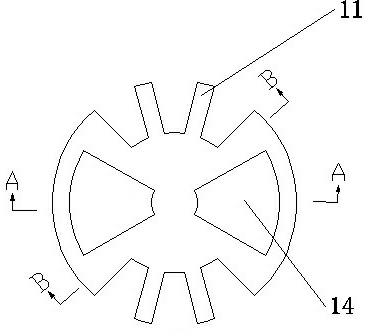

[0053] In Embodiment 2, on the basis of Embodiment 1, changes are made to the radiator and the lampshade of the fixed ring, and the installation method of the two is snapped instead of the threaded connection installation method in Embodiment 1. Specifically: if Figure 9 , Figure 10 As shown, a notch 12 is recessed around the heat sink body, and the inner wall of the fixed ring lampshade 2 is protruded with a convex notch 13 fitted with the notch, and the end surface of one end of the fixed ring lampshade protruding with a lamp bead lens is reflective Arched arc surface; when installing, directly push the heat sink body of the radiator 3 into the lampshade of the fixed ring, and the installation of the radiator and the lampshade of the fixed ring is completed after the notch cooperates with the convex notch. After the heat sink and the lampshade of the fixing ring are fixed and installed, the lamp pins clamp the LED pins, and the lamp beads also press the lampshade of the f...

Embodiment 3

[0055] This embodiment 3 also makes changes on the basis of embodiment 1, specifically: as Figure 11 , Figure 12 , Figure 13 As shown, the insulating plastic rubber sleeve 4 is an integrated structure, and the insulating plastic rubber sleeve is composed of a symmetrical fan-shaped packing body and a snap ring 6 connected between the two fan-shaped packing bodies, and the lamp pins pass through the corresponding insulating plastic rubber sleeve; The connecting terminal at the end of the lamp pin is a contact copper sheet 18 that fastens the LED pin, the contact copper sheet is arranged in an insulating plastic rubber sleeve, and the contact copper sheet is provided with a card slot that allows the LED pin to be inserted into the contact copper sheet 19. The diameter of the card slot is smaller than the diameter of the LED pin; the outer diameter of the contact copper sheet is larger than the outer diameter of the lamp pin. The outer diameter of the snap ring 6 is greater ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com