Aspherical mirror detection method based on phase measurement deflectometry

An aspheric mirror and detection method technology, which is applied in the detection of aspheric mirrors and the field of optical detection, can solve the problems of high requirements for the environment used, small dynamic range of measurement, and particularly large impact on accuracy, and achieve calculation formulas and calculations. Simple process, large measurement dynamic range, and the effect of suppressing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

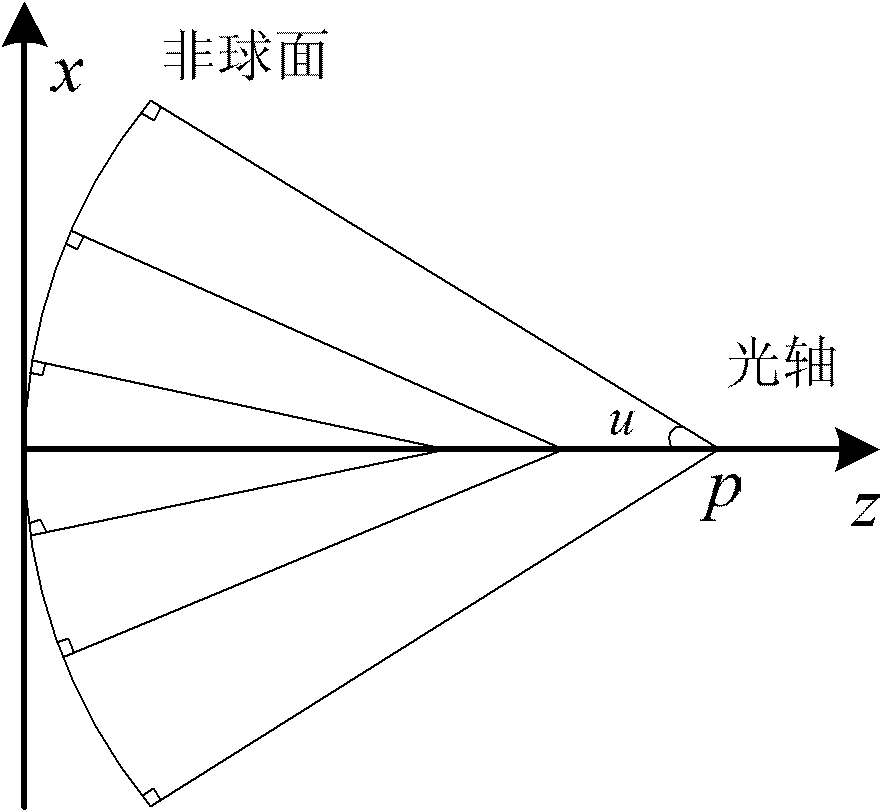

[0021] Such as figure 1 As shown, in fact, any kind of aspheric surface has a normal convergence, and its normal and the optical axis intersect at different points and form different angles, such as figure 1 Shown. The aspheric surface can not only be characterized by its rectangular coordinate system equation, but also by the longitudinal normal aberration and the angle between the normal and the optical axis. For the convenience of description, the present invention refers to the distance between the aspheric surface vertex and the intersection point of the aspheric surface normal and the optical axis as the normal distance, which is represented by p; the inclination of the aspheric surface normal to the optical axis is called the normal angle, Use u to represent. Obviously, in addition to the rectangular coordinate system, the aspheric surface shape can also be characterized by the property of the normal sink, that is, the continuous function g:p=g(u) between the normal dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com