Method for manufacturing end face of high-power optical fiber laser

A technology of fiber laser and manufacturing method, which is applied in the laser field, can solve problems such as difficult operation and failure to meet requirements, and achieve the effects of high flatness, high finish, and enlarged output area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

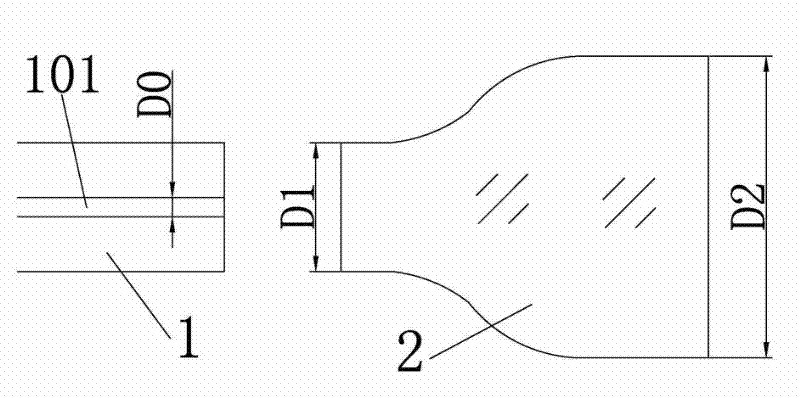

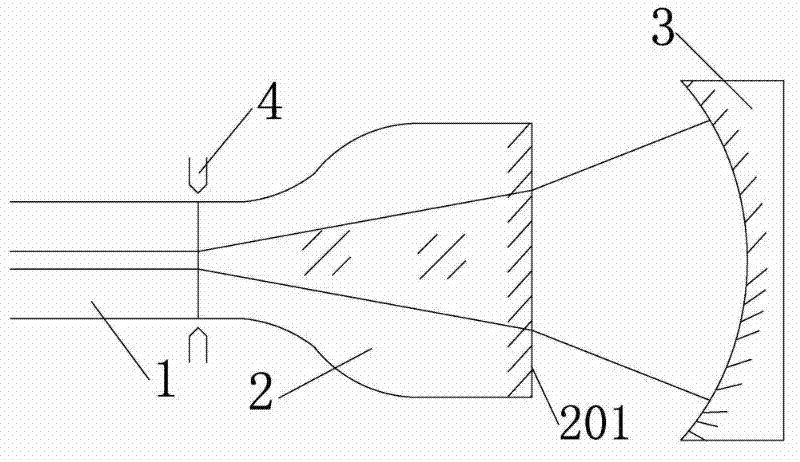

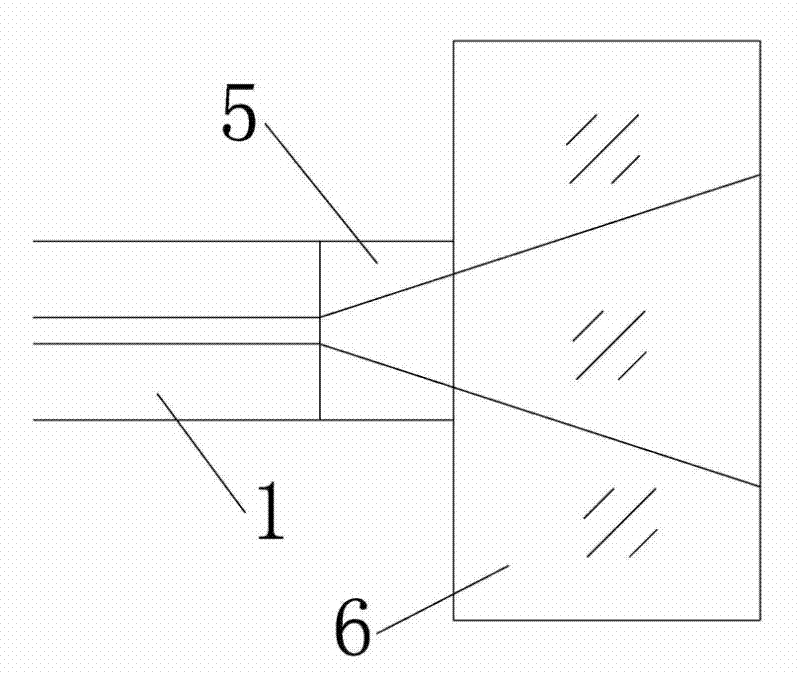

[0016] Such as figure 1 , 2 As shown, the present invention adopts an optical element 2, which is directly melt-connected with the end face of the optical fiber 1 of the high-power fiber laser; the diameter D1 of one end of the optical element 2 is equal to or similar to the diameter of the high-power optical fiber, and the other end is tapered or horn-shaped. The diameter is D2 (D2>D1), and the end surface 201 is coated with an anti-reflection film layer, and forms a laser output end with a plano-concave mirror 3 . Since D2 can be made larger and can be much larger than the diameter D0 of the core 101 of the optical fiber 1, it is easier to handle and obtain high end-face quality.

[0017] The basic principle of a high-power fiber laser end face manufacturing method of the present invention is as follows: figure 1 As shown, it specifically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com