System and method for realizing cogeneration by using heat-conducting oil furnace and semiconductor power generation device

A heat-conducting oil furnace and power generation device technology, which is applied in the direction of generators/motors, heat storage heaters, electrical components, etc., can solve the problems of using a large amount of cooling water, only losing it to the atmosphere, and utilizing the latent heat of cooling liquid vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

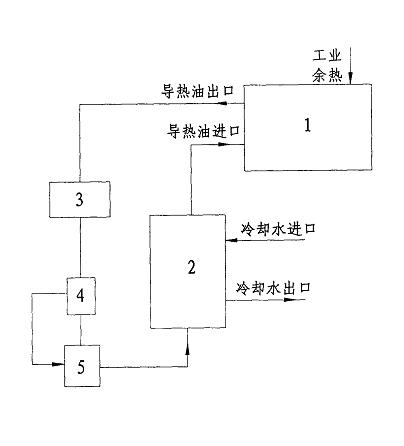

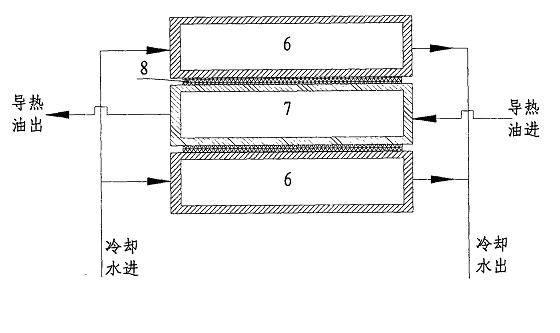

[0021] Such as figure 1 , 2 Shown are the block diagram and structure diagram of the prior art semiconductor thermoelectric generator power generation device, which are marked as: 1-heat exchanger, 2-semiconductor thermoelectric generator, 3-oil storage tank, 4-thermostat, 5- Oil pump, 6-heat conduction oil pipeline, 7-cooling water pipe, 8-semiconductor thermoelectric power generation chip.

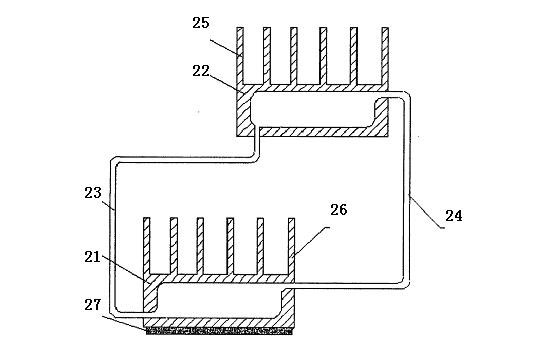

[0022] Such as image 3 Shown is the cooling device used for the semiconductor thermoelectric power generation module, the picture marks: 21-radiator, 22-condenser, 23-pipe, 24-air pipe, 25,26-thin fin, 27-existing Semiconductor thermoelectric power generation module in technology.

[0023] The semiconductor thermoelectric power generation device 50 includes a semiconductor thermoelectric power generation module 68, a power generation module hot end 58, a phase ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com