Propylene polymers for lab/medical devices

A polymer, propylene technology, used in laboratory utensils, laboratory containers, hypodermic instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

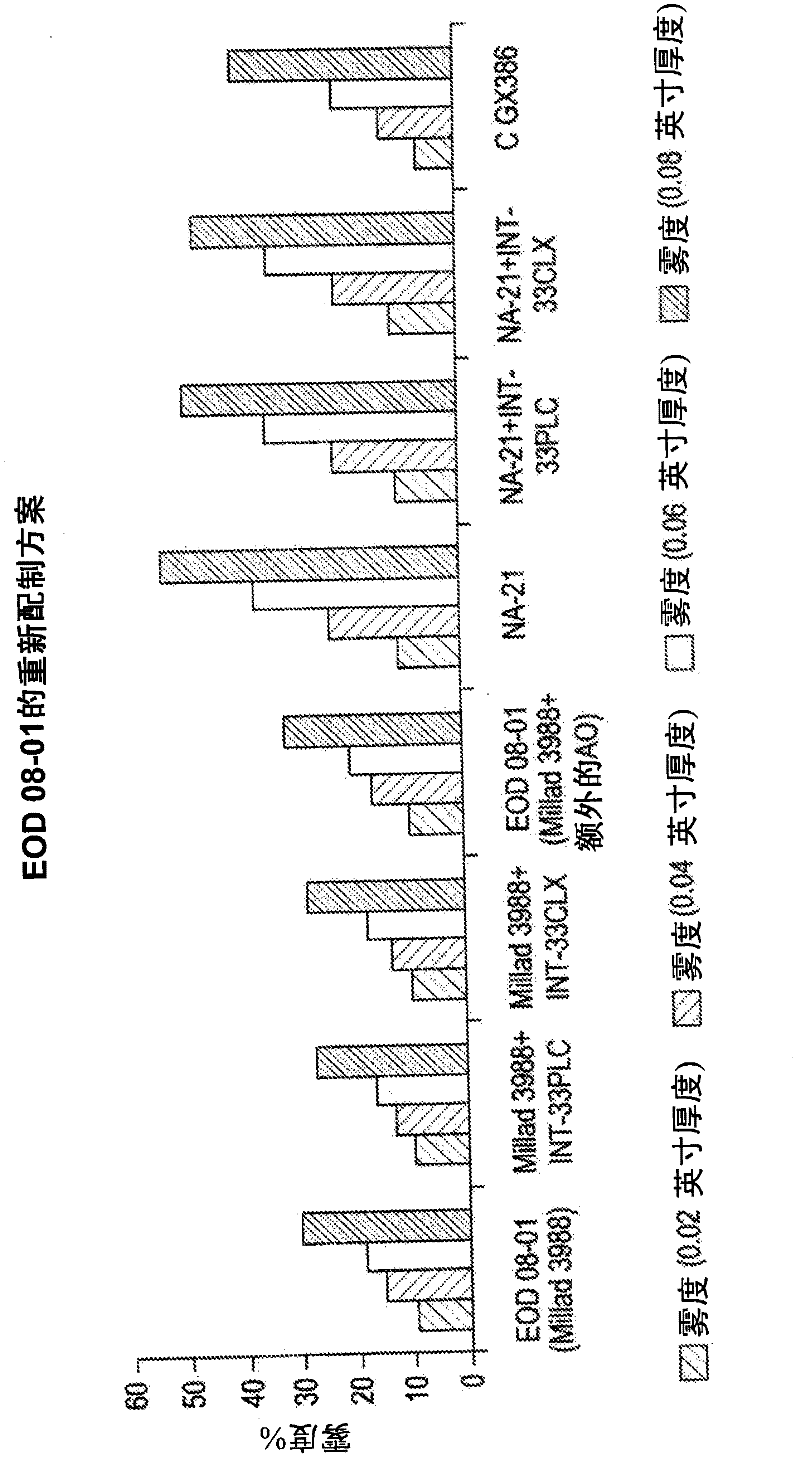

Image

Examples

Embodiment

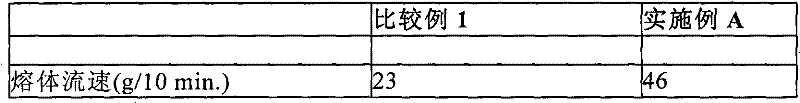

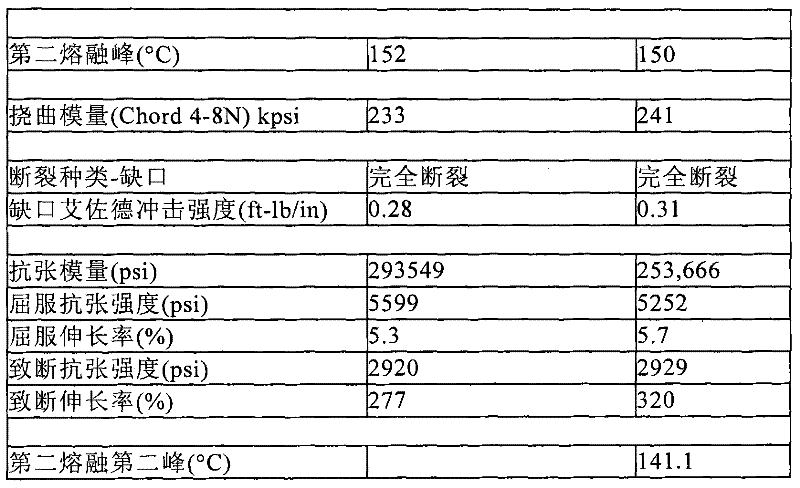

[0067] Metallocene Catalyst System SiMe 2 (2-methyl-4-phenylindenyl) 2 ZrCl 2 A 40-melt flow ethylene / propylene random copolymer polypropylene (Example A) was prepared. A 40-melt flow ethylene / propylene random copolymer polypropylene (Example B) was prepared using the same metallocene catalyst system as in Example A. Example A had an ethylene content of 0.5% by weight and Example B had an ethylene content of 1.0% by weight. Examples A and B are formulated for laboratory and medical devices with high clarity, high toughness, and resistance to the levels of gamma radiation conventionally used to aseptically process polypropylene. Table 1 provides the characteristics of Example A.

[0068] Table 1. Characteristics of Example A

[0069] Melt flow rate (g / 10min)

Embodiment B

[0095] Example B: Random Copolymer Polypropylene Containing 1.0 wt% C2 Prepared Using Metallocene Catalyst Technology

Embodiment A

[0096] Example A: Random copolymer polypropylene containing 0.5% by weight of C2 prepared using metallocene catalyst technology

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com