Pesticide emulsifiable granules and method for preparing same

A technology of emulsifiers and pesticides, applied in the field of emulsifiable granules and their preparation, can solve the problems of easy particle agglomeration, affecting performance, disintegration and dispersibility, and the decline of emulsification performance and suspension rate quality indicators, so as to promote social and ecological benefits The effect of improving, reducing toxicity, and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

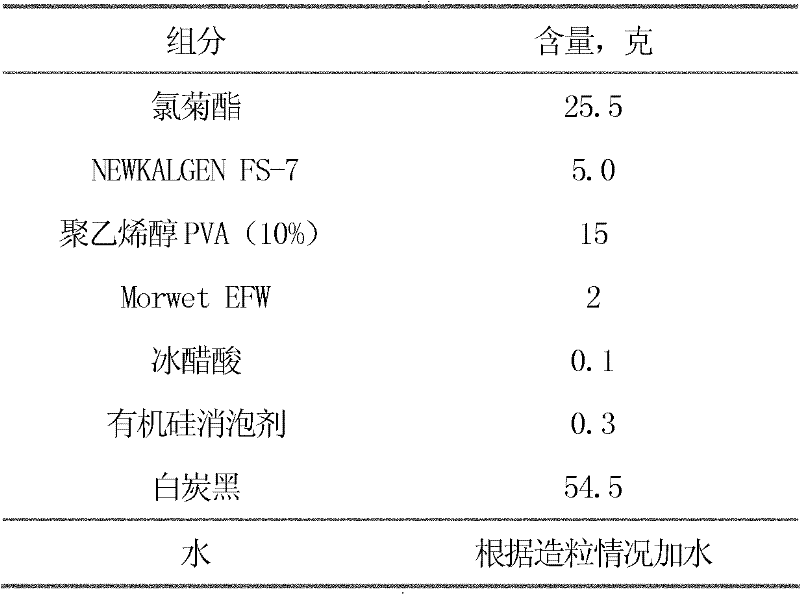

[0034] The composition ratio of table 1 embodiment 1

[0035]

[0036] Add 25.5g of permethrin raw material to 5.0g of emulsifier NEWKALGEN FS-7 (Japanese Takemoto Oils and Fats) and stir evenly (oil phase); Add 15g of water phase and stir to form a milky white paste; add the mixed emulsion to the carrier silica and stir, adjust the pH value to about 6 with 0.1g of glacial acetic acid, 0.3g of silicone defoamer, wetting and dispersing agent Morwet EFW 2.0g was stirred evenly to form a kneaded pre-granulation mixture, which was then granulated by pan-type pressure and dried to obtain 25.5% permethrin EG.

Embodiment 2

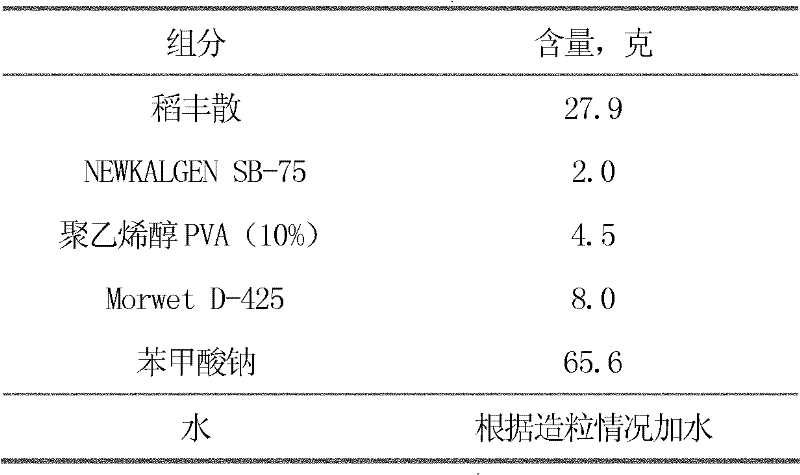

[0038] The composition ratio of table 2 embodiment 2

[0039]

[0040] Add 27.9g of Daofengsan ester raw material to 2.0g of emulsifier NEWKALGEN SB-75 (Japanese Takemoto Oil) and stir evenly (oil phase); pour the configured oil phase into 10% water-soluble polymer PVA 4.5g of the water phase and stirred to form a milky white paste; the mixed emulsion was added to the carrier sodium benzoate and stirred, and the wetting and dispersing agent MorwetD-4258.0g was stirred evenly to form a kneading pre-granulation mixture, and then added by pan Press and granulate, dry and dry to obtain 27.90% Daofengsan EG.

Embodiment 3

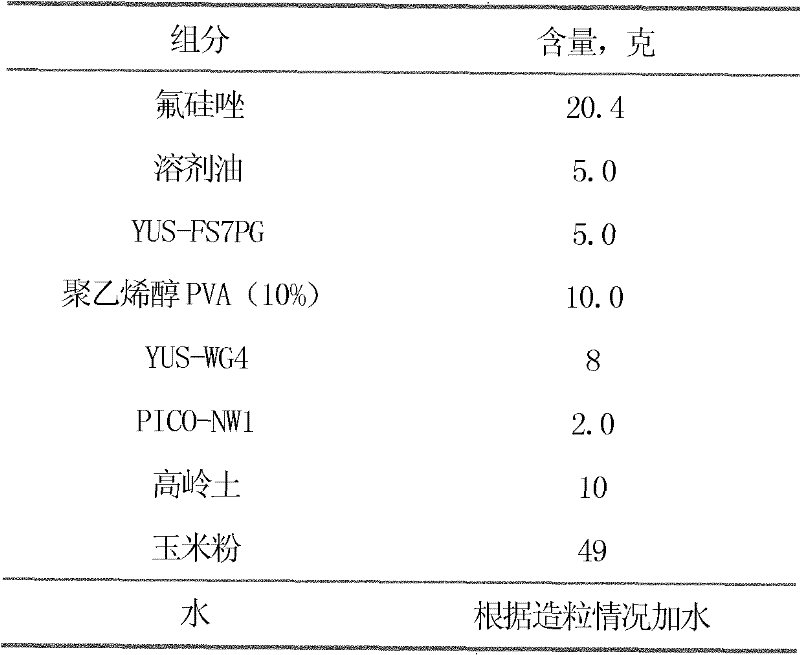

[0042] The composition ratio of table 3 embodiment 3

[0043]

[0044]Dissolve 20.4g of flusilazole original drug with 5g of solvent oil, then add 5.0g of emulsifier YUS-FS7PG (Japanese bamboo oil) and stir evenly (oil phase); pour the prepared oil phase into 10% Add 10g of water-soluble polymer PVA to the water phase and stir to form a milky white paste; add the mixed emulsion to the carrier corn flour and stir, wetting and dispersing agent YUS-WG48.0g, PICO-NW12.0g, kaolin 10 g was stirred evenly to form a kneading pre-granulation mixture, which was then granulated by pan-type pressure and dried to obtain 17.1% flusilazole EG.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com