A wet method treatment process of purified flue gas with a water collection function in the process and a processing apparatus thereof

A treatment process and treatment device technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as large water consumption, no water recycling or utilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

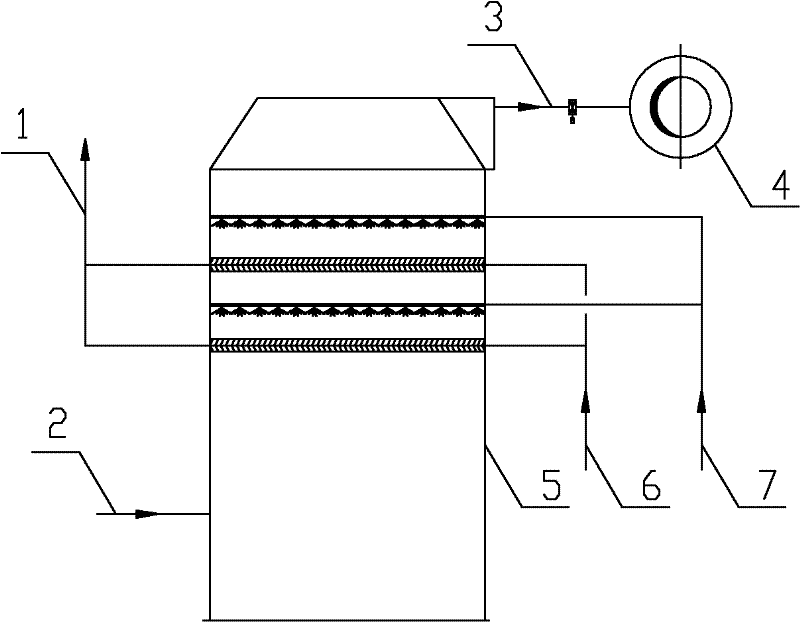

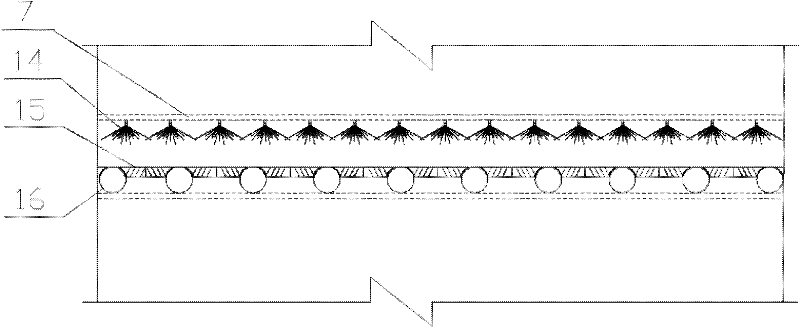

[0028] Such as figure 1 and image 3 As shown, an integrated demister 15 and a cooling device 16 are arranged in the absorption tower 5, and the two ends of the cooling device 16 are respectively connected to the coolant outlet pipe 1 and the coolant inlet pipe 6. In the integrated demister 15 A sprinkler 14 is arranged above the cooling device 16 (that is, a cooler with a demister function), and the sprinkler 14 is connected to the flushing water pipe 7 . The process flow is: the flue gas enters the absorption tower 5 from the original flue 2, and undergoes wet purification in the absorption tower 5, including the water collection function of the demister 15, the cooling device 16 and the water sprayer 14, and then cleans the flue gas It enters the chimney 4 through the clean flue 3 and is discharged.

Embodiment 2

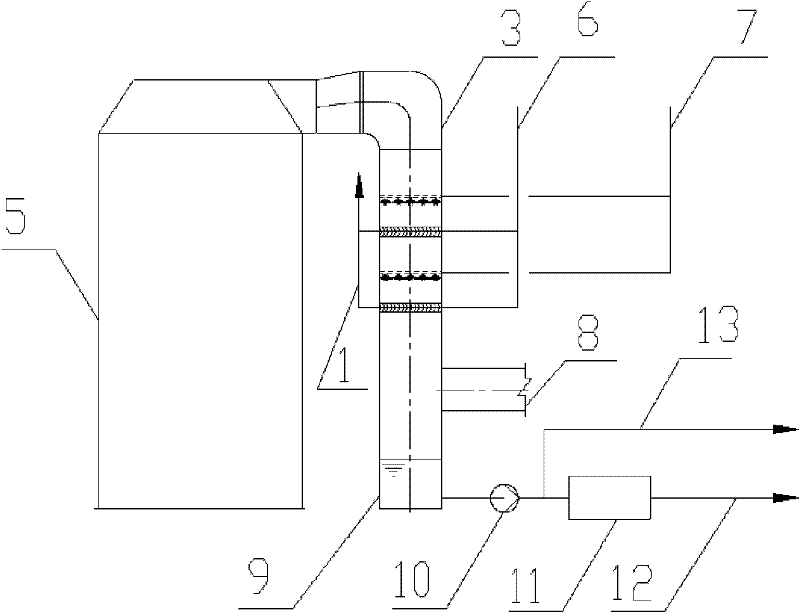

[0030] Such as figure 2 and image 3 As shown, an integrated demister 15 and a cooling device 16 are arranged in the clean flue 3, and the two ends of the cooling device 16 are respectively connected to the coolant outlet pipe 1 and the coolant inlet pipe 6. In the integrated demister 15 and cooling device 16 (that is, the cooler with demister function) is provided with sprinkler 14, and sprinkler 14 is connected to flushing water pipe 7. The clean flue 3 is provided with a clean flue to chimney pipe 8 for discharging clean flue gas, and the clean flue 3 is connected with a recovery water tower 9, and the recovery water tower 9 is connected with a recovery water pump 10, and the recovery water pump 10 is connected with two pipelines, One path is the recycled water pipeline 12 connected to the water treatment device 11 , and the other path is the recycled water desulfurization pipeline 13 . The process flow of this embodiment can be easily understood through the accompanying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com