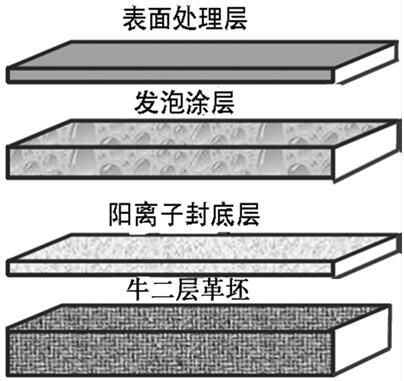

A kind of preparation method of hydrolysis-resistant foamed bovine split leather

A two-layer leather, hydrolysis-resistant technology, applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as low peel strength, powdering, poor hydrolysis resistance, etc., to improve market competitiveness and hydrolysis resistance Excellent performance and the effect of improving peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of cationic water-based polyurethane back sealer, water-based polyurethane foam slurry and surface layer slurry, in parts by weight

[0032] a) Preparation of cationic water-based polyurethane back sealer: 70 parts of 25% solid content N -Methyldiethanolamine ( N -MDEA) type cationic waterborne polyurethane and 2 parts of epoxy resin waterborne crosslinking agent are mixed evenly;

[0033] b) Preparation of water-based polyurethane foaming slurry: 55 parts of anionic aliphatic polyether foaming water-based polyurethane with a solid content of 50%, 0.5 parts of polyacrylate alkali thickener, and 3 parts of stearamide emulsion for foam stabilization agent, 0.2 parts of leveling agent, 2 parts of water-based color paste, and 3 parts of fiber wood powder are mixed evenly, and the foam slurry is made into a foam slurry through an intelligent dynamic generator to obtain a foam with a foaming ratio of 1.5 times and a viscosity of 5000 Pa·s slurry;

[0034] D...

Embodiment 2

[0041](1) Preparation of cationic water-based polyurethane back sealer, water-based polyurethane foam slurry and surface layer slurry, in parts by weight

[0042] a) Preparation of cationic waterborne polyurethane bottom sealer: 80 parts of 20% solid content N -Ethyldiethanolamine ( N -PDEA) type cationic water-based polyurethane and 4 parts of blocked polyisocyanate crosslinking agent are mixed evenly;

[0043] b) Preparation of water-based polyurethane foaming slurry: 70 parts of anionic aromatic polycarbonate foaming water-based polyurethane with a solid content of 55%, 1.5 parts of polyurethane associative thickener, 5 parts of silicone foam stabilizer, Mix 1 part of leveling agent, 3 parts of water-based color paste, and 5 parts of kaolin evenly, and make a foam slurry through an intelligent dynamic generator to obtain a foam slurry with a foaming ratio of 1.8 times and a viscosity of 8000 Pa s;

[0044] Described viscosity is the viscosity when slurry temperature is 25...

Embodiment 3

[0051] (1) Preparation of cationic water-based polyurethane back sealer, water-based polyurethane foam slurry and surface layer slurry, in parts by weight

[0052] a) Preparation of cationic waterborne polyurethane bottom sealer: 90 parts of 15% solid content N -Ethyldiethanolamine ( N -PDEA) and N -Propyldiethanolamine ( N -BDEA) type cationic water-based polyurethane, 5 parts of polyethylenimine and epoxy resin composite cross-linking agent are mixed evenly;

[0053] b) Preparation of water-based polyurethane foaming slurry: 95 parts of anionic polyether-type and polycarbonate-type foaming water-based polyurethane with a solid content of 60%, 2 parts of polyacrylate alkali thickener and polyurethane-based associative thickener Thickener compound, 6 parts of stearamide emulsion and alkanolamide compound, 1.6 parts of leveling agent, 4 parts of water-based color paste, 8 parts of fiber wood powder and kaolin are mixed evenly and made by intelligent dynamic generator Foam s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com