Calcium-based moving bed full-dry desulfurization and dust removal method and device

A technology of desulfurization and dust removal and moving bed, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as desulfurization agent consumption, complaints from surrounding residents, visual pollution, etc., and achieve sulfur dioxide bypass regulation for old materials reuse, The effect of saving operating costs and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

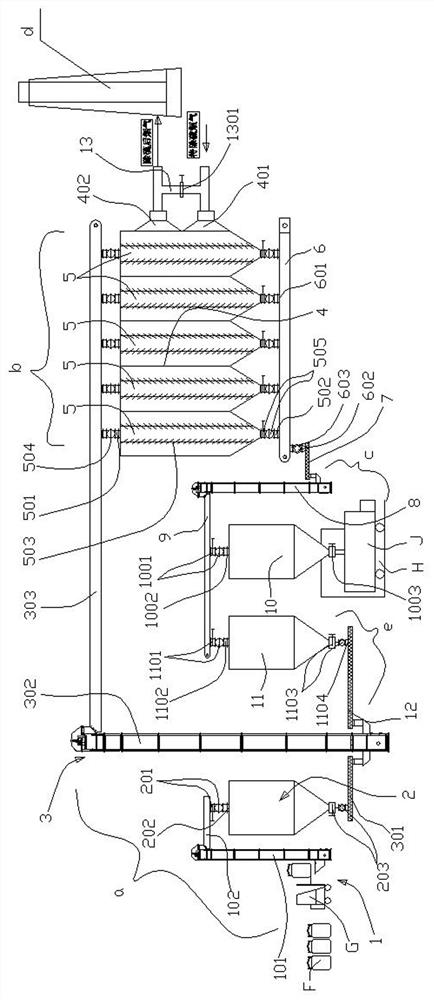

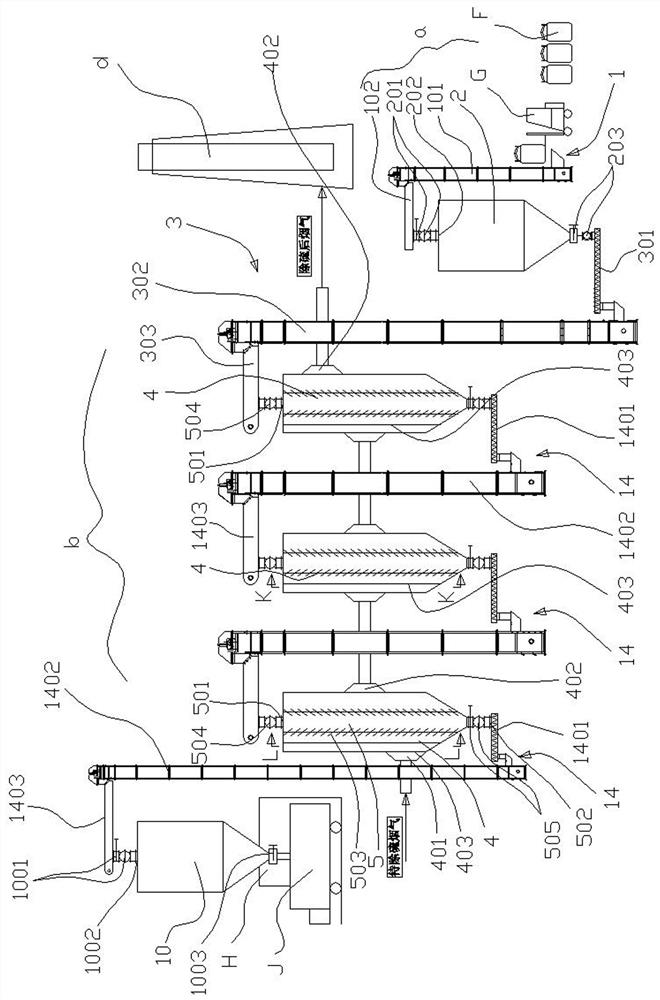

[0052] The present invention will be further described in connection with the accompanying drawings and examples:

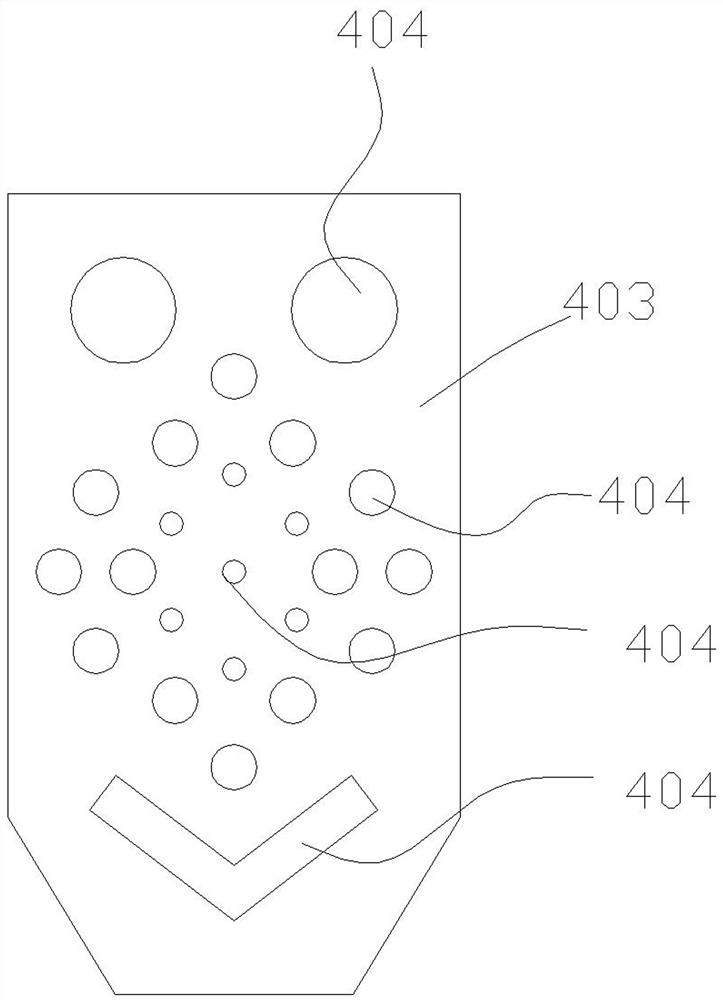

[0053] like figure 1 As shown, the calcium-based moving bed of the present invention Example 1 includes an upper system A, a desulfurization dust removal system B, an discharge system C, a chimney D, a material A including a raw material delivery mechanism 1, and a raw material The material bin 2 connected to the mechanism 1, the desulfurizer transmitting the laminate 3, the raw material delivery mechanism 1 includes a raw material conveyor 101, a raw material conveyor belt 102 connected to the raw dam 101, and the raw material conveyor belt 102 outlet. Connected to the raw material inlet 202 with the inlet plate valve and the star discharge valve 201 of the raw material bin 2, the desulfurizing agent transmission and laminating mechanism 3 includes an outlet plate valve and a star unloading valve 203 with the raw pad 2. The raw material conveyor 301 coupled to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com