Closed water cooling system being capable of producing condensed water

A cooling system and closed water technology, which is applied in household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of high closed water temperature of air-cooled thermal power units, increased infrastructure investment, and increased water consumption of air-cooled thermal power units. , to achieve the effect of improving cooling efficiency, reducing investment and lowering evaporation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

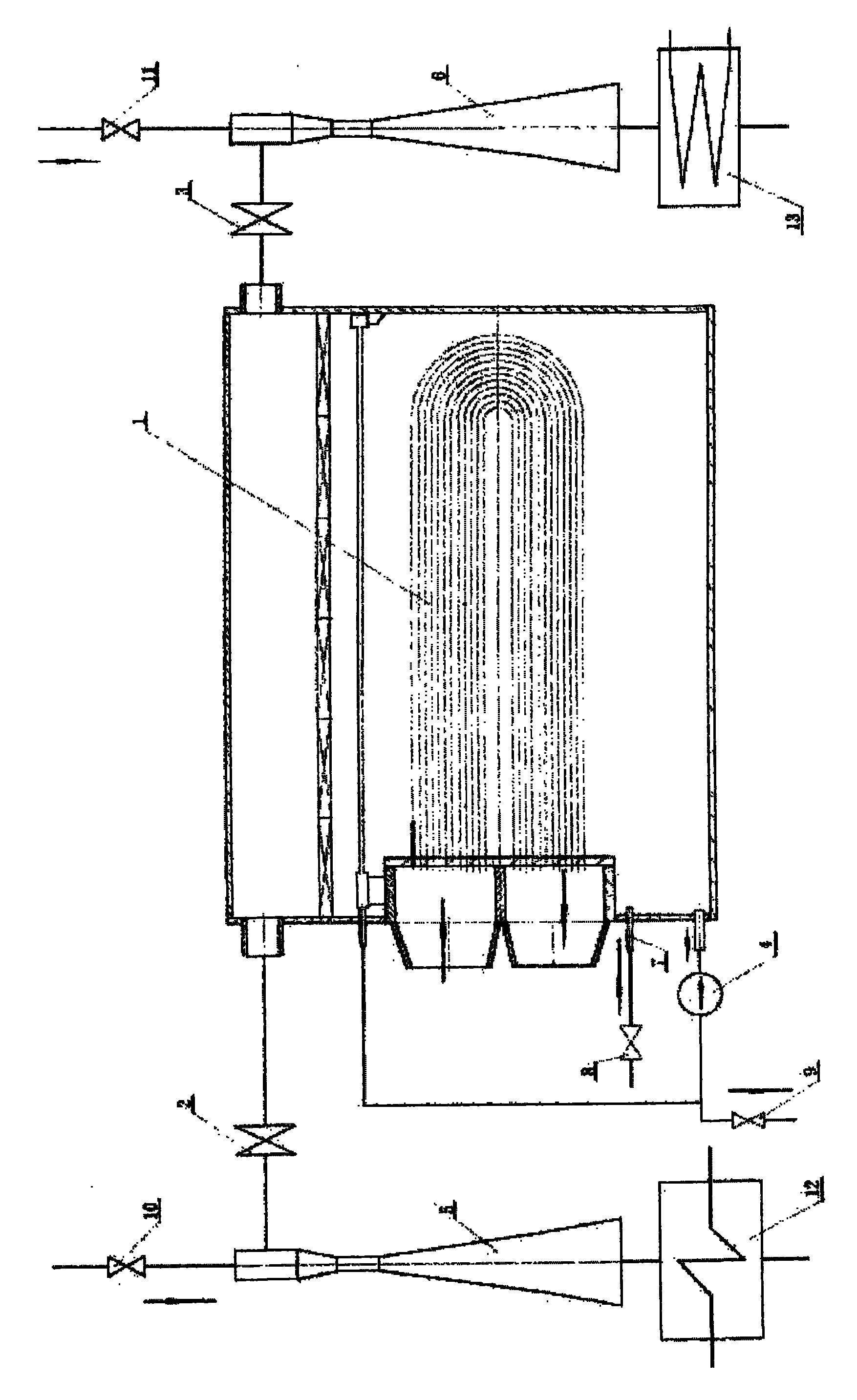

[0037] Now take a closed water cooling system with a closed water flow rate of 2000t / h and a closed water temperature drop of 7K, from 37°C to 30°C, which can produce condensed water as an example to illustrate the optimal way to realize the invention:

[0038] The closed water cooling system capable of producing condensed water in the present invention includes a closed water cooler body (1) capable of producing condensed water, a vacuum butterfly valve A (2), a vacuum butterfly valve B (3), and a membrane water pump (4) , steam injector A (5), steam injector B (6), ultrafiltration industrial water replenishment pipe (7), ultrafiltration industrial water replenishment regulating valve (8), salt balance drain valve (9), 5-stage steam extraction Steam inlet regulating valve (10), plant auxiliary steam inlet steam regulating valve (11), liquid level sensor and DCS control system; 0.001MPa (a) to 0.004MPa ( a) The vacuum state in the interval is realized by steam ejector A (5) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com