Anti-wrapping closed hydrostatic slideway structure of numerical control machine

A technology of static pressure guide rails and CNC machine tools, which is applied to metal processing machinery parts, large fixed members, metal processing equipment, etc., and can solve problems such as cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

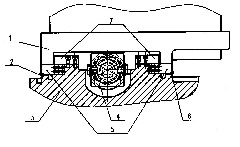

[0011] In this design, the anti-inclusive closed static pressure guide rail structure of the CNC machine tool is installed on the horizontal CNC lathe, such as figure 1 As shown, it is characterized in that the lower ends of the left and right sides of the bed saddle 1 are respectively fixed with movable guide rails 5 by screws, and the upper inner sides of the bed 3 are respectively fixed with fixed guide rails 7 by screws, and several oil chambers are respectively distributed on the three end surfaces of the movable guide rails 5 . A left oil baffle 2 and a right oil baffle 6 are respectively installed under the two outer sides of the saddle to prevent the static pressure oil from leaking to the bed, and the servo motor 4 is the driving power source for the axial feed of the saddle 1 .

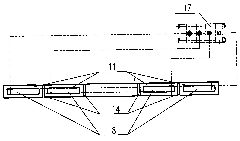

[0012] The movable guide rail 5 of this structure chooses the oil chamber structure form with a horizontal oil return groove, figure 2 It is the oil chamber 8 on the inner side elevation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com