Steel sheet pile coefferdam structure and topdown construction method thereof

A technology of steel sheet pile cofferdam and construction method, which is applied in basic structure engineering, hoisting device, construction and other directions, can solve the problems of difficult recovery of steel, easy sinking of caisson, and high engineering cost, and achieves reduction of permanent construction steel, Improve overall stability and reduce construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

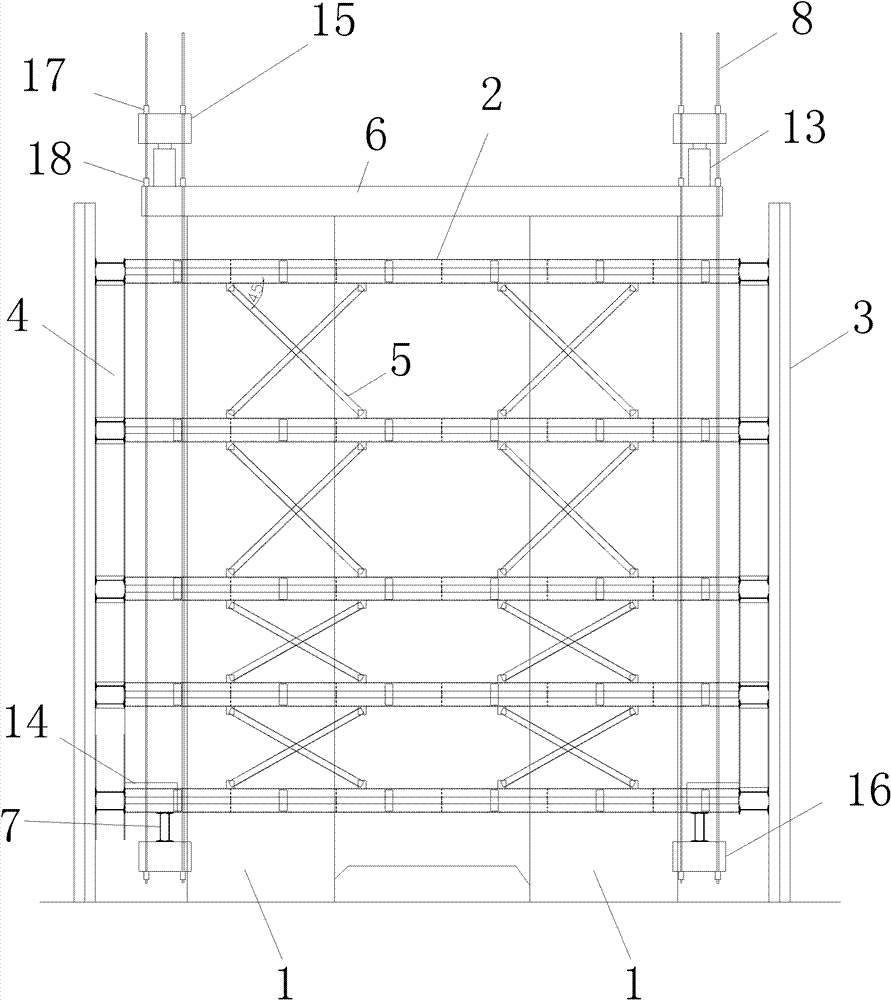

[0039] The present invention will be further described below in conjunction with drawings and embodiments.

[0040] In this example, the materials used are:

[0041] Bracket: 2I 45a I-shaped steel, 6m long.

[0042] Jack: 120 tons.

[0043] Steel pad reinforcement block: 2I 45a I-shaped steel.

[0044] Lower beam: 2I 45a I-shaped steel, 16m long.

[0045] Upper beam: 2I 45a I-shaped steel, 11m long.

[0046] Hanging block: 2I 45a I-shaped steel.

[0047] Jacking block: 2I 45a I-shaped steel.

[0048] Steel sheet pile: Closed Larsen steel sheet pile SKSP-IV type, 24m long.

[0049] Sling: 32mm in diameter, fine-tie threaded steel sling.

[0050] Steel casing: diameter 280mm.

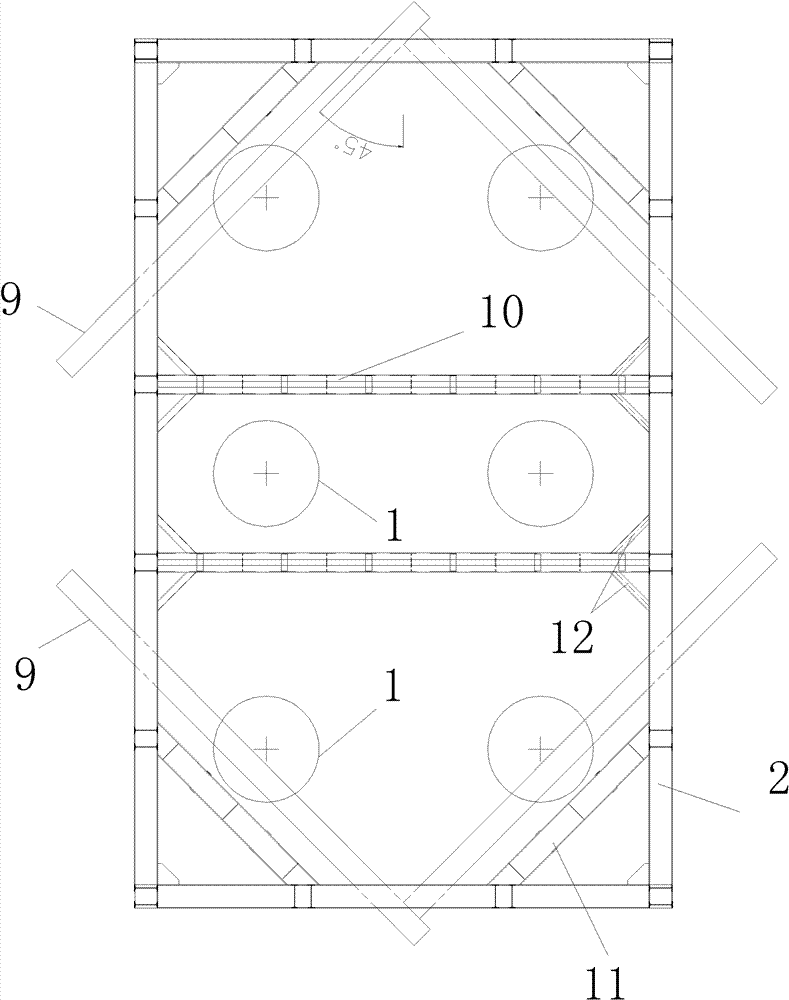

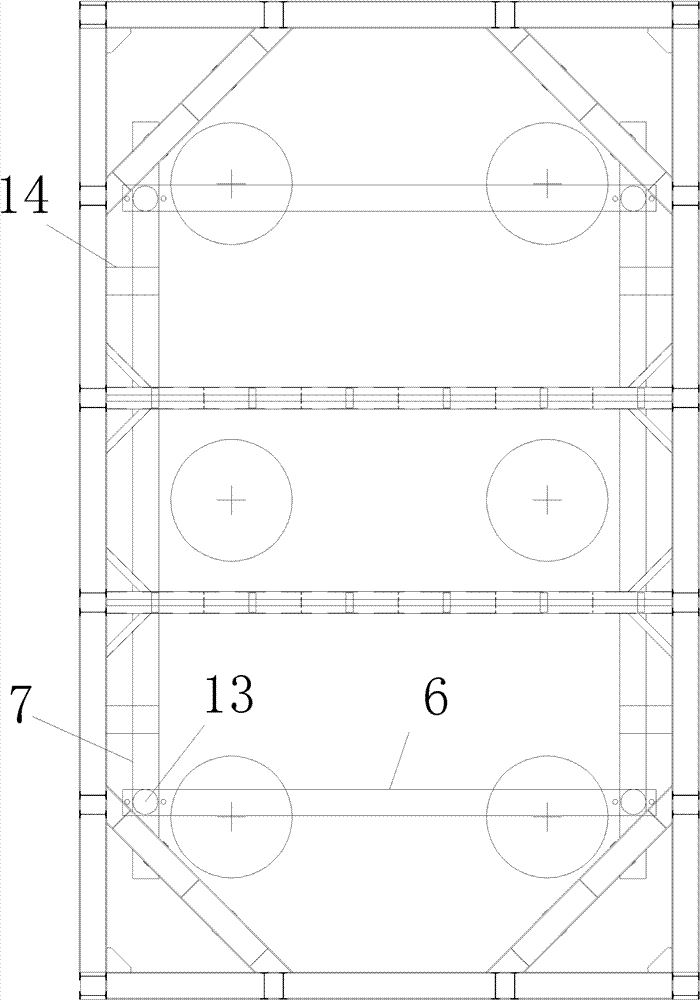

[0051] Such as Figure 1~4 The steel sheet pile cofferdam structure shown includes a steel casing, 5-layer purlins and steel sheet piles inserted around the purlins. The lower part of the steel casing is welded with brackets to form a temporary support platform, and the upper and lower layers of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com