Induction cooker structure

An induction cooker and wire reel technology, which is used in household stoves/stoves, electric heating fuels, and household heating, etc., can solve the problem of the reduction of the actual power of the induction cooker, the inaccurate temperature setting and temperature measurement, and the inability to guarantee the distance between the wire reel and the bottom of the pot. and other problems, to achieve the effect of simplifying assembly, prolonging service life and saving mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, further illustrate the feature of a kind of induction cooker structure of the present invention and the technical effect that it obtains.

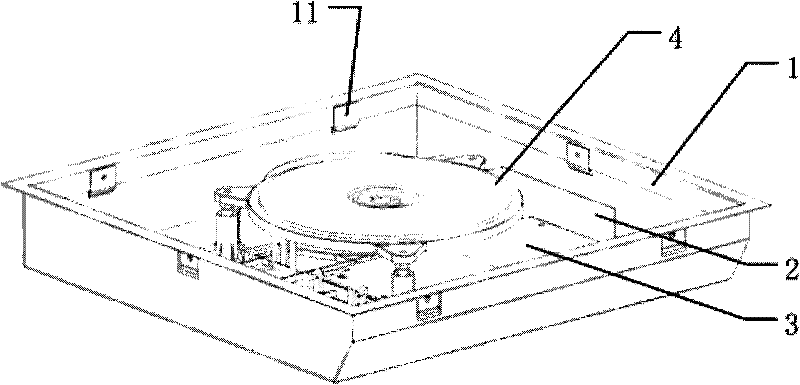

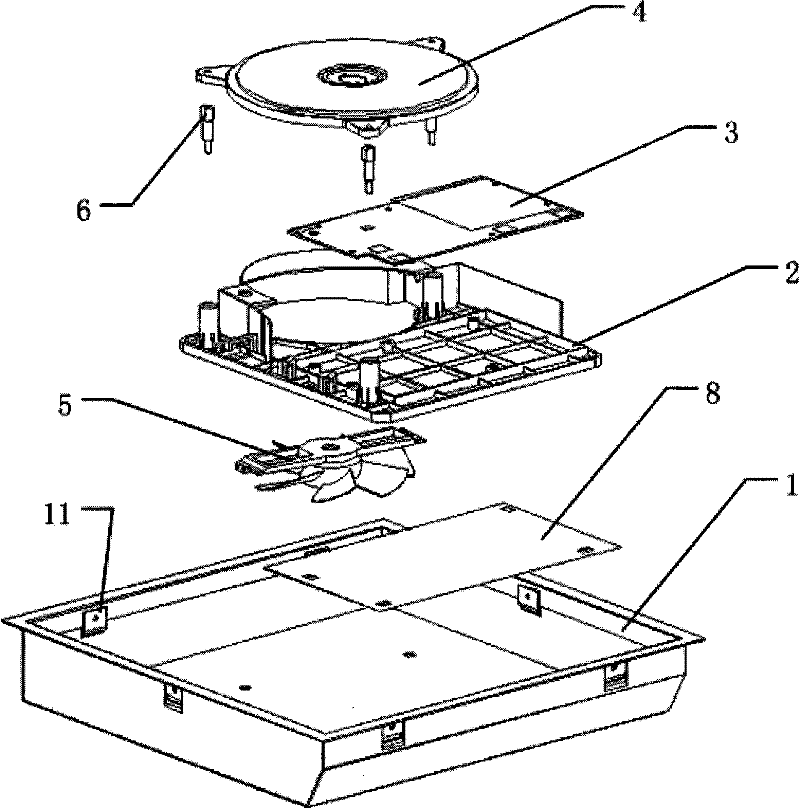

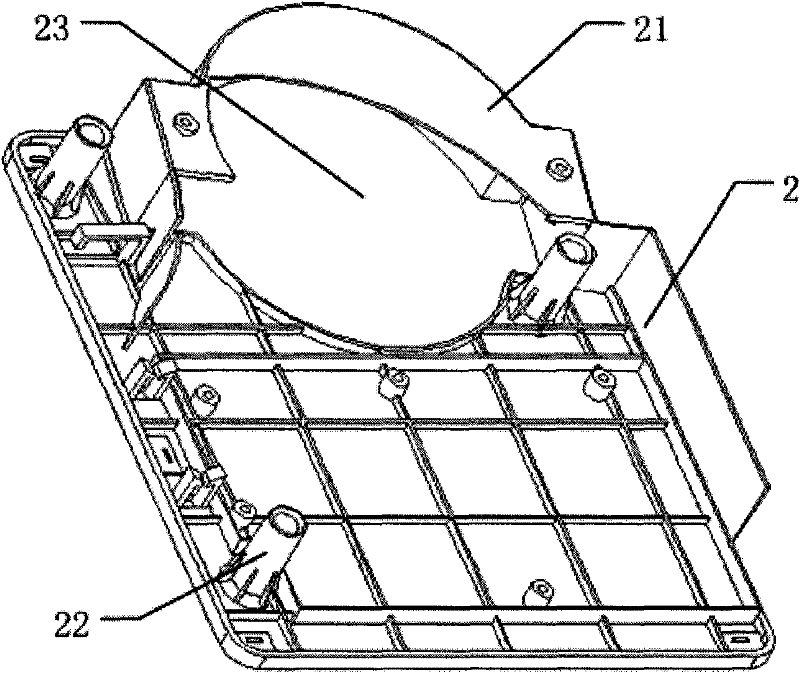

[0022] like Figure 1 to Figure 4 As shown, it is a schematic view of the internal structure of the electromagnetic oven of the present invention after removing the ceramic plate, a schematic view of the decomposition, a schematic view of the structural appearance of the plastic tray, and a schematic cross-sectional view of the assembly of the coil.

[0023] It can be seen from the figure that all functional components of the assembled induction cooker except the ceramic plate are installed in the base of the metal shell. The induction cooker structure includes: a base 1 of a metal shell, an upper cover assembly covering the base (respectively including a ceramic plate and an upper cover frame not shown), and a circuit board 3 and a wire reel 4 installed in the induction cooker body. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com