Sealed laminated electrical connector for helium filled disk drive

A technology for disk drives and electrical connectors, which is applied in the direction of instruments, magnetic recording heads, and the surface of magnetic heads, and can solve problems such as reliability degradation, data loss, and impact on head performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

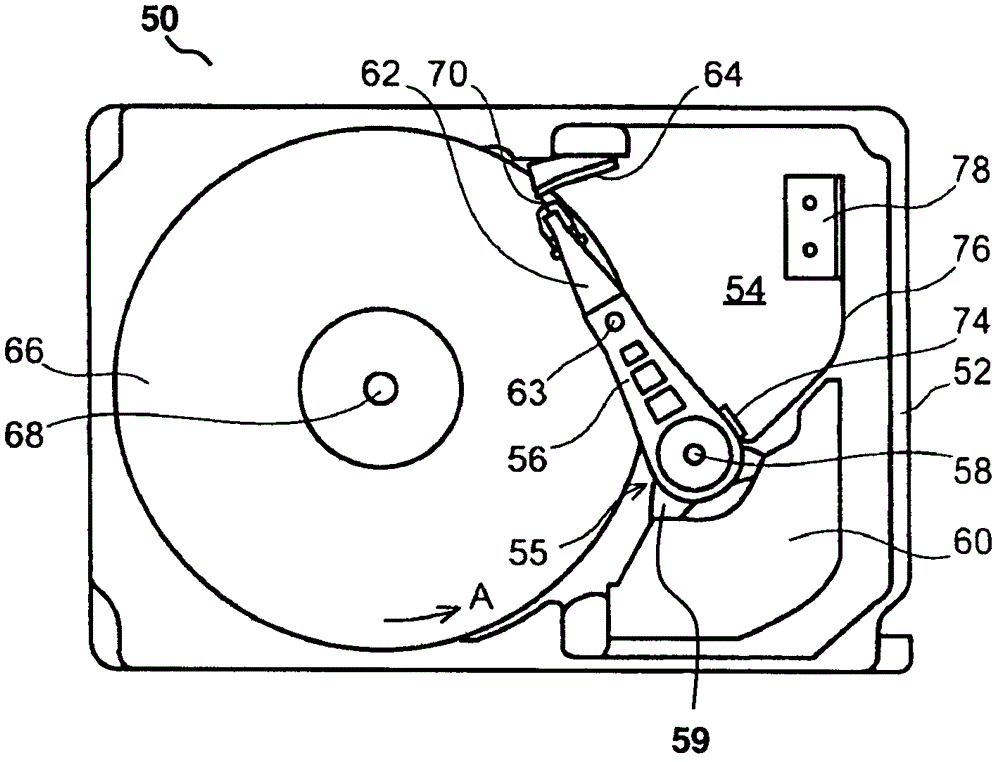

[0019] FIG. 1 is a plan view showing a schematic diagram of a magnetic disk drive 50 according to the prior art. Disk drive base 52 forms a disk drive enclosure 54 with an adjoining top cover (not shown to allow viewing of internal components). Enclosed within disk drive housing 54 is head gimbal assembly (HGA) 62, which includes a read / write head that can be lifted from the surface of platter 66 by interaction between loading tang 70 and ramp 64. Loading and unloading. Disk platter 66, also enclosed in disk drive housing 54, is mounted on spindle motor 68, which is attached to disk drive chassis 52 and enables disk platter 66 to rotate as indicated by arrow A. The HGA 62 is attached to the actuator arm 56 , for example by swaging at the hole 63 . Actuator arm 56 belongs to head actuator 55 which is arranged in disk drive housing 54 and which pivots about pivot bearing barrel 58 in response to torque from voice coil motor 59 . This torque is produced by the electromagnet in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com