Device structure with channel-oxide-nanotube super junction and preparation method thereof

A device structure, nanotube technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, diodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

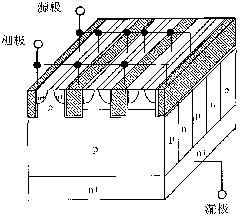

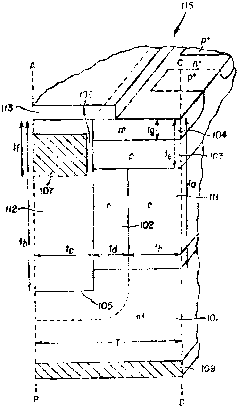

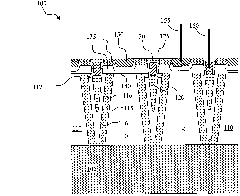

[0034] image 3 A cross-sectional view of a trenched nanotube metal oxide semiconductor field effect transistor (MOSFET) device 100 according to the present invention is shown. The MOSFET element is formed in a P-type epitaxial layer 110 on the N+ substrate 105 . A plurality of trenched nanotubes 115 and a plurality of trenches are formed in the epitaxial layer 110 . The trench sidewalls are slightly beveled to form a tapered trench. As an example, the side walls may be slightly sloped at 87-89 degrees. Each trench sidewall is covered by N+ epitaxial layer 115 . Another lightly doped P- epitaxial layer 116 is grown over N+ epitaxial layer 115 . Due to the remaining trench width and the slope angle of the trench, the sidewalls of the P- epitaxial layer 116 meet toward the bottom and fully fill the bottom of the trench. The remaining central portion of the trench is filled with a dielectric such as silicon oxide 120 . The MOSFET device 100 also includes a trench gate 130 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com