Circulating heat-increasing energy-saving brick bed furnace

A traveling type, kang stove technology, which is applied to stoves/stoves with hot water devices, household heating, heating methods, etc. Fully utilized thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

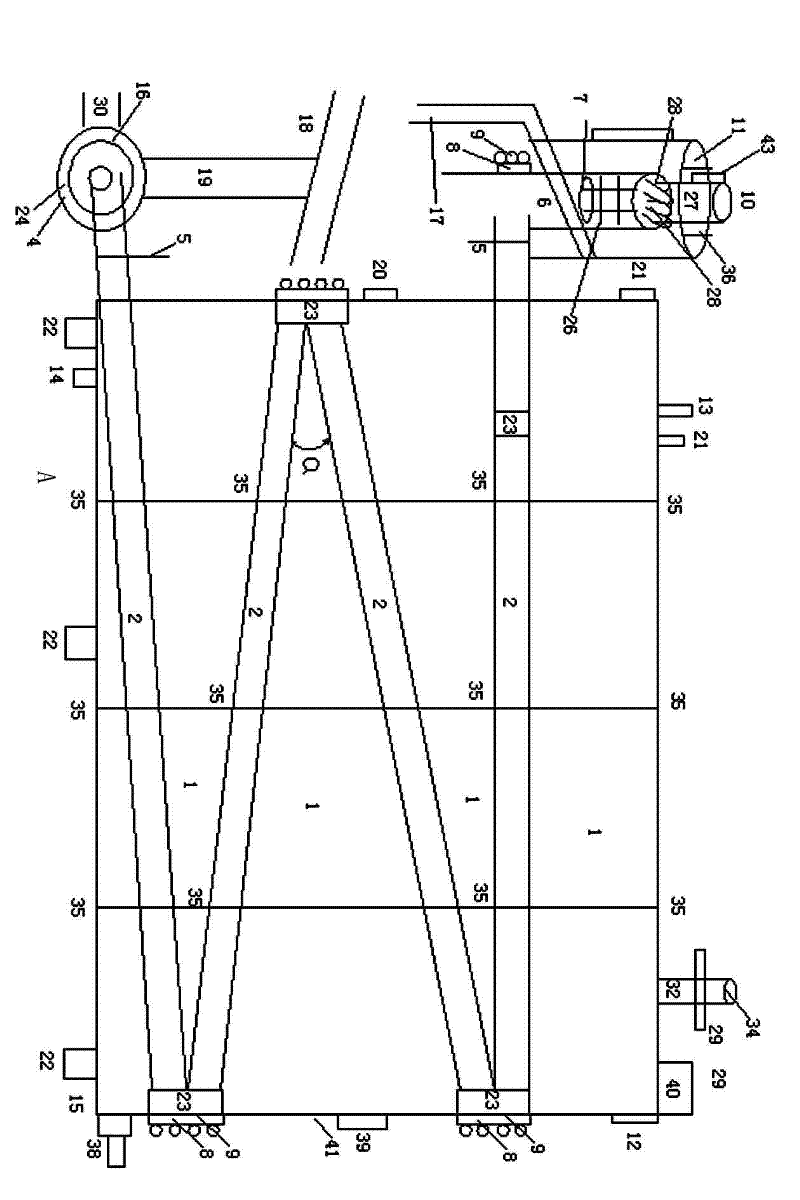

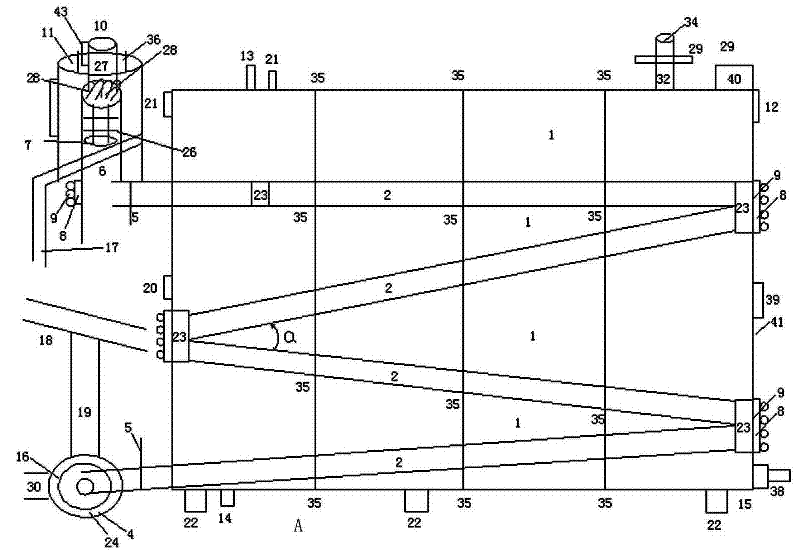

[0023] as attached figure 1 , shown in 2, a kind of itinerant heat-increasing and energy-saving kang furnace of the present invention, this kang furnace mainly comprises furnace body, combustion system, exhaust system, cleaning system, and body of furnace is the rectangular parallelepiped airtight container of interior water 1, and is arranged in the furnace body The pyrotechnic pipeline 2 of the circuit, the pyrotechnic pipeline 2 can be provided with one or more layers according to needs, the space outside the pyrotechnic pipeline 2 is filled with water 1, and a bracket is set between the pyrotechnic pipeline 2 and the lower inner wall of the furnace body to prevent pyrotechnic Pipeline 2 is in direct contact with the lower inner wall to avoid burning and deformation of the lower inner wall due to excessive temperature. The effect is best when the support is arranged in a mesh structure, because the mesh form can also provide better support while ensuring isolation The pyrot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com