Method and device for utilizing exhaust gas of haydite rotary kiln

A rotary kiln and tail gas technology, which is applied in the field of tail gas utilization of ceramsite rotary kiln, can solve the problems that the sludge raw material cannot fully utilize the heat source and needs to be improved, and achieve the effect of shortening the curing time, improving the product quality and improving the early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

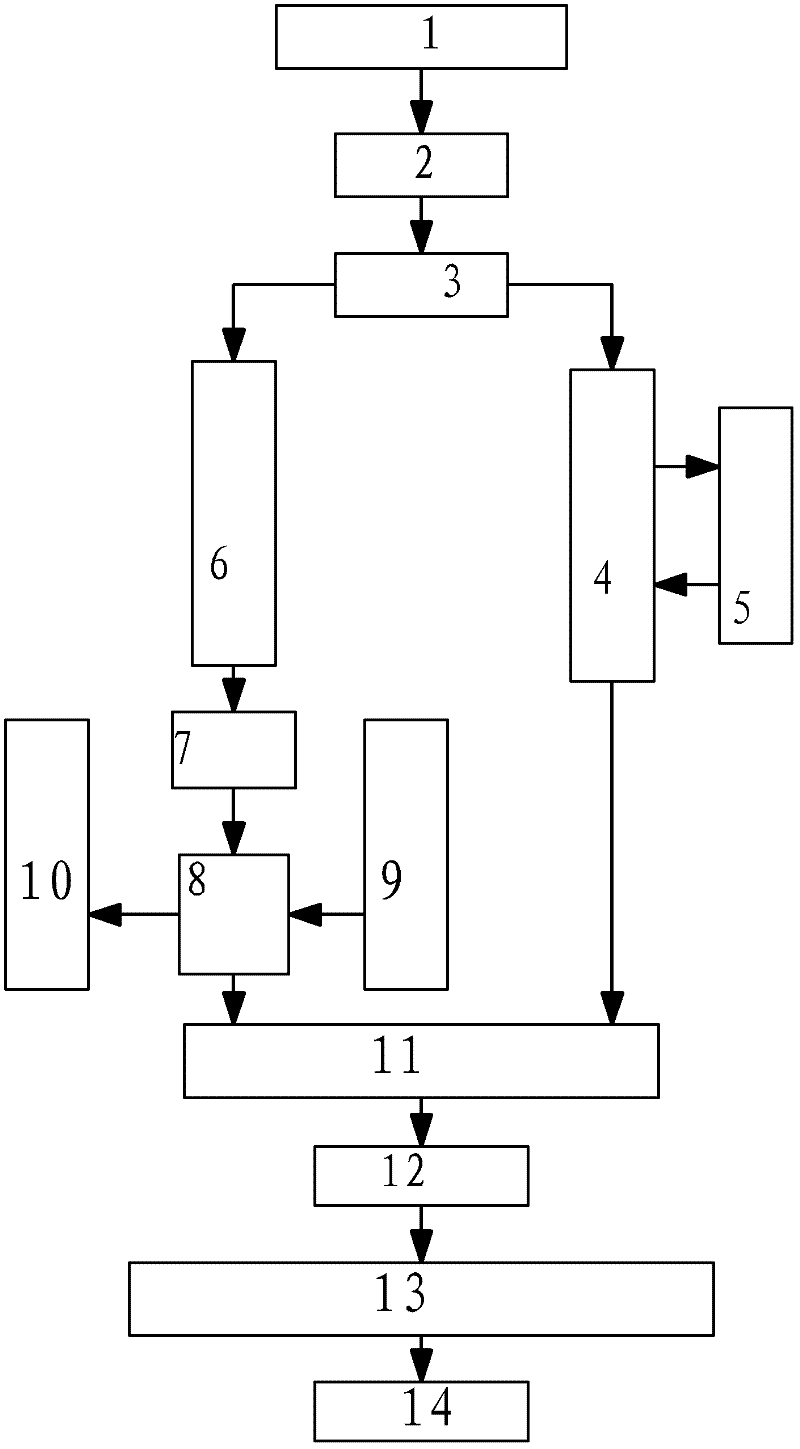

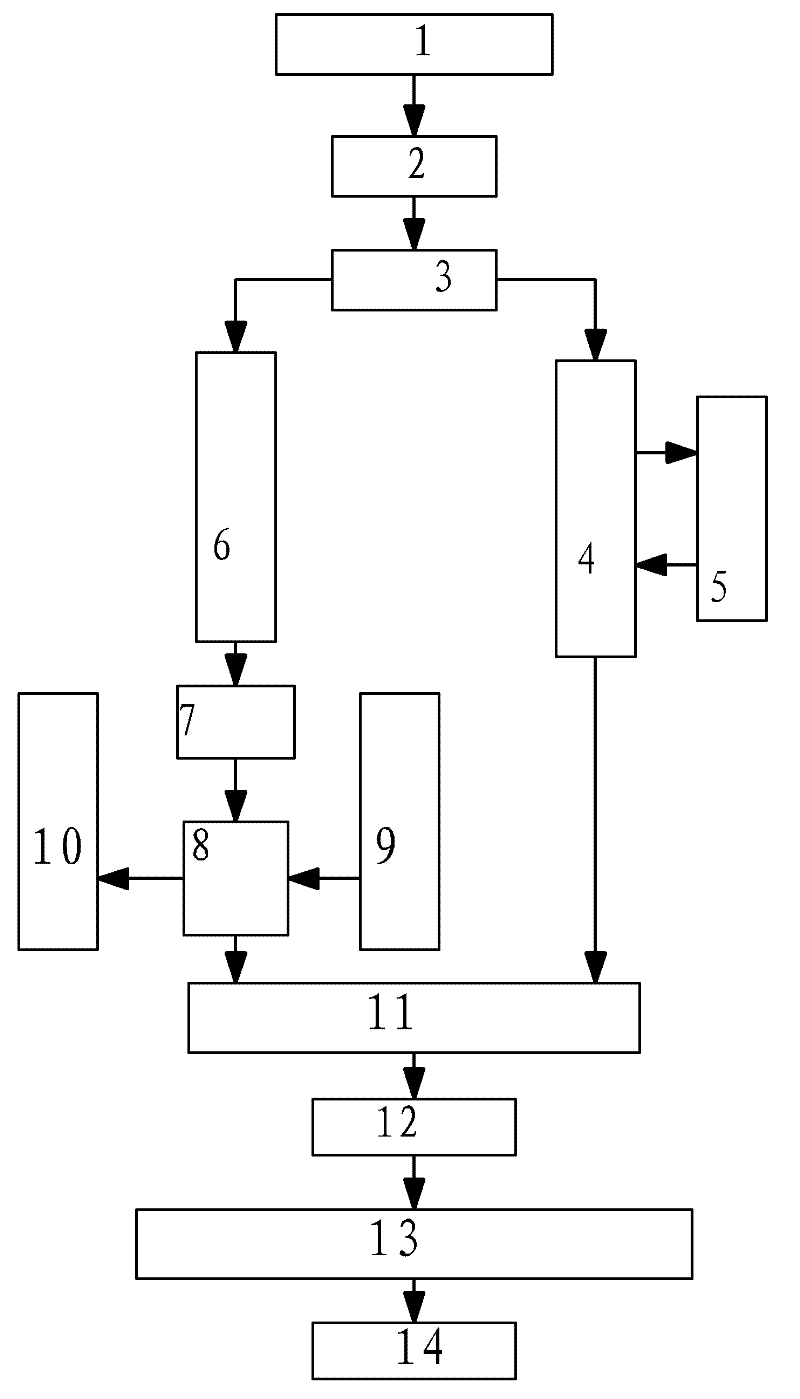

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0025] Such as figure 1 As shown, the device for utilizing the tail gas of the ceramsite rotary kiln includes a ceramsite rotary kiln 1. The tail of the ceramsite rotary kiln 1 is connected with a flue 3, and the flue 3 has two outlet pipes, and the two outlet pipes correspond to each other one by one. The dryer 8 and the heat exchanger 4 are connected.

[0026] The ceramsite rotary kiln 1 is in the shape of a cylinder, and its hollow inner cavity is the firing kiln cavity of ceramsite. The ceramsite rotary kiln 1 is arranged obliquely, with a low entrance end and a high exit end, that is, the head end of the kiln body is inclined downward. The tail end is inclined upwards, and the ceramsite rotary kiln 1 can rotate at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com