Light-emitting diode (LED) multi-chip integrated packaging device

An integrated packaging and multi-chip technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of reduced life, low reliability, and low luminous efficiency, and achieve increased reliability, improved light efficiency, and long service life. prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

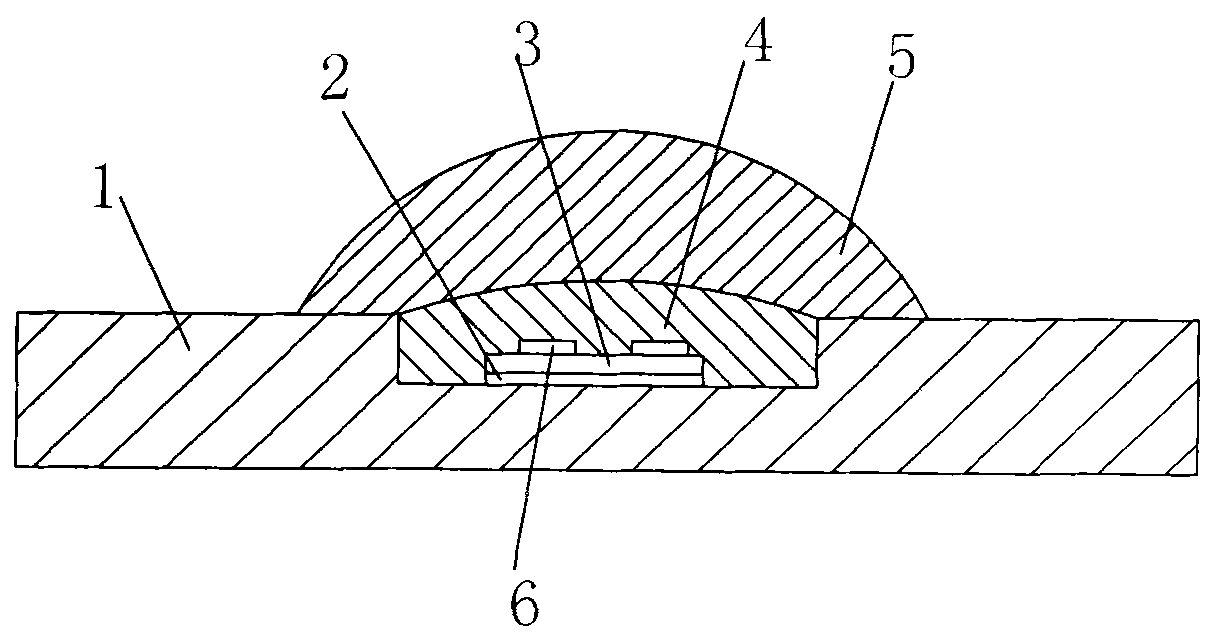

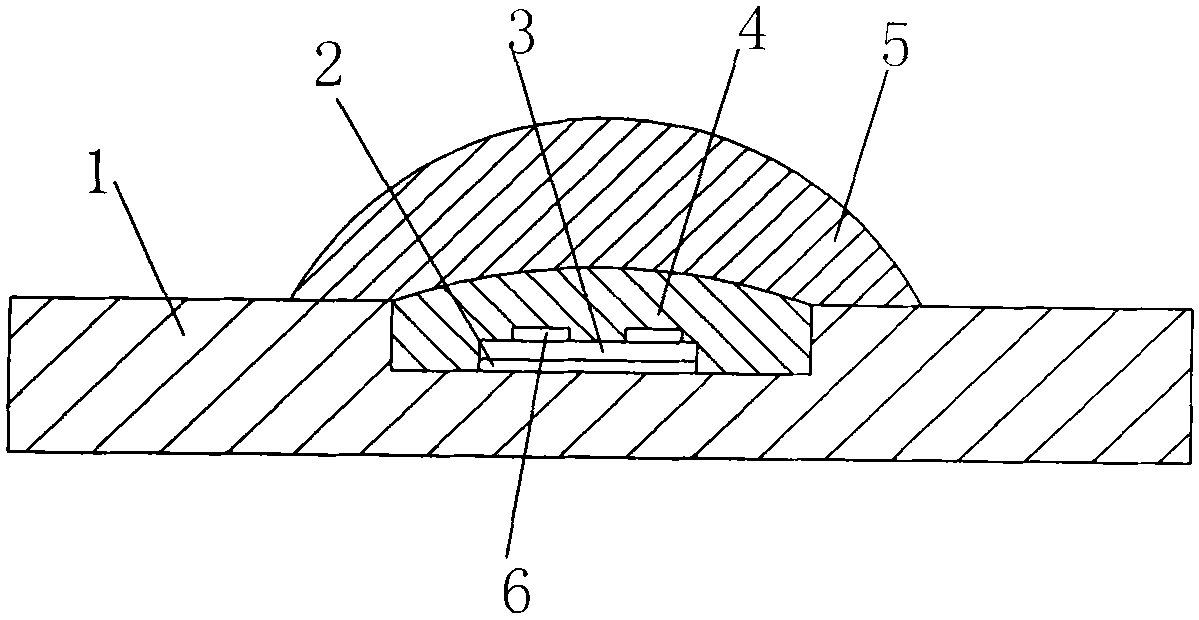

[0009] A kind of LED multi-chip integrated packaging device of the present invention, as figure 1 As shown, it includes a substrate 1 and several chips 6, and it also includes a silicon chip 3, a phosphor layer 4 and an optical silicone lens 5. The bottom of the silicon chip 3 is plated with a gold-plated layer, and several chips 6 are welded in series and parallel on the silicon chip. A series-parallel circuit is formed on the chip 3, the substrate 1 is a red copper plate, a square groove is opened on the substrate 1, the bottom of the square groove is electroplated with nickel silver, the silicon chip 3 is located in the square groove, and an alloy is formed between the silicon chip 3 and the bottom of the square groove. The soldering piece 2 fixes the silicon chip 3 in the square groove; the phosphor layer 4 fills and covers the silicon chip 3 and forms a convex surface on the upper surface, and the silicone lens 5 is fixed on the substrate 1 in a hemispherical shape to cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com