Photovoltaic interconnector for absorbing stress

An interconnection strip and photovoltaic technology, which is applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of reduced battery life and high cost of interconnection strips, and achieve the effect of reducing debris and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

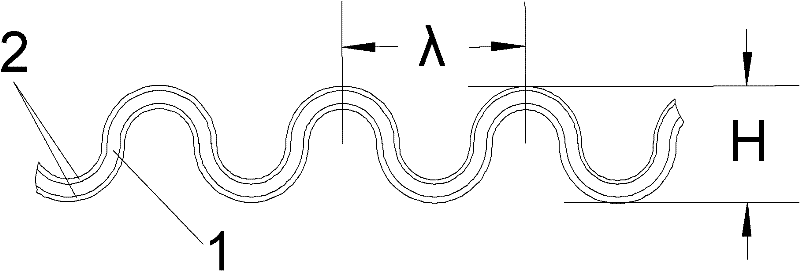

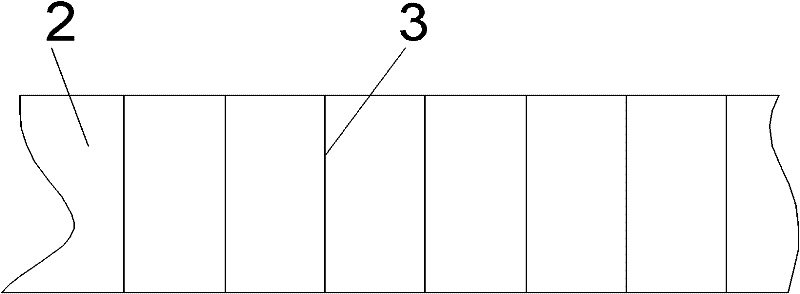

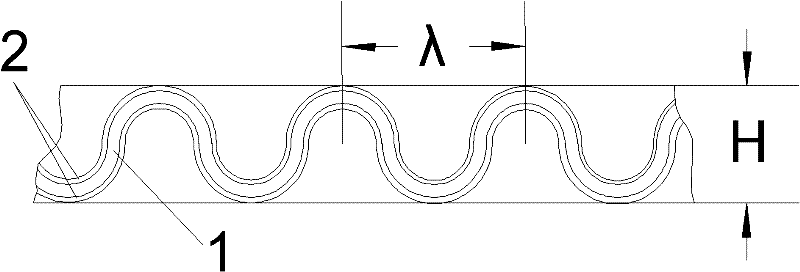

[0020] Such as figure 1 , 2 As shown in the interconnection strip, 1 in the figure is the base copper strip, its thickness is 0.05mm, and its width is 0.1mm, 2 is the tin alloy layer, its thickness is 0.001mm, and the composition of the tin alloy is calculated as: Cu 0.10 , Ag0.1, Si 0.001, P 0.09, and the balance is Sn. The entire interconnection strip is sinusoidal along its longitudinal direction, its wavelength λ=1mm, and its peak height H=0.005mm.

Embodiment 2

[0022] The situation of embodiment 1 is basically the same, except that the thickness of the copper strip is 0.2mm, and the width is 2.0mm, and the thickness of the tin alloy layer is 0.035mm, and the composition of the tin alloy is calculated in % by weight: Cu 2.00, Ag3.5,, Si0.006, P0.002, Pb10, the balance is Sn, its wavelength λ=10mm, and the peak height H=0.01mm. Other situations are identical with embodiment 1.

Embodiment 3

[0024] The situation of embodiment 1 is basically the same, but the thickness of the copper strip is 0.16mm, and the width is 1.6mm, and the thickness of the tin alloy layer is 0.02mm, and the composition of the tin alloy is calculated in % by weight: Cu 1.0, Ag 2, Si 0.0. .003, P0.05, Pb32, the balance is Sn, its wavelength λ=5mm, peak height H=0.007mm. Other situations are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com