Umbrella unfolding type airship air bag

An umbrella-type, airbag technology, applied in the field of airships, can solve problems such as weak wind resistance, difficulty in high-altitude flight, complex structure, etc., and achieve the effect of reducing strength, large volume, and increasing wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

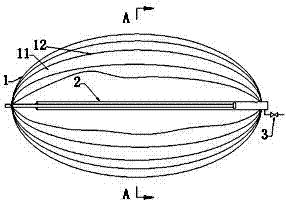

[0011] like figure 1 As shown, the present invention is made up of capsule body 1, axial stretching device 2 and inflation valve 3, and airbag stretching device 2 is installed in capsule body 1, and the gas supply port of inflation valve 3 communicates with the inner chamber of capsule body 1.

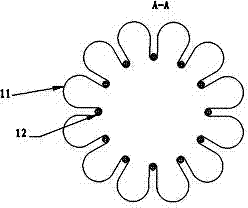

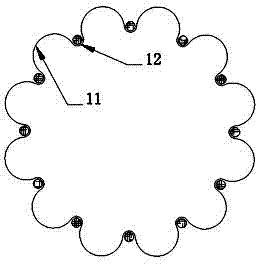

[0012] like figure 2 , 3 As shown, the capsule body 1 is composed of a group of valve-shaped capsule skins 11 and a group of longitudinal ribs 12. A group of valve-shaped capsule skins 11 are made of airtight airbag cloth. Adjacent valve-shaped capsule skins are heat-sealed at the junction Bonded together, a group of longitudinal ribs 12 is composed of strong and flexible threads, and a group of longitudinal ribs 12 are respectively fixed at the junction of adjacent flap-shaped capsule skins. The petal-shaped bag skin 11 can be made of airtight balloon cloth, airship airbag cloth or film material, and the longitudinal rib 12 can be made of high-strength nylon rope, Kevlar or other p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com