Macromolecular environmentally-friendly sand-fixing dust suppressant

A technology of dust suppressant and polymer, which is applied in the field of polymer environment-friendly sand-fixing and dust-suppressing agent and its synthesis, can solve the problem of high price of sand-fixing agent, achieve good application prospect and promotion value, good stability and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

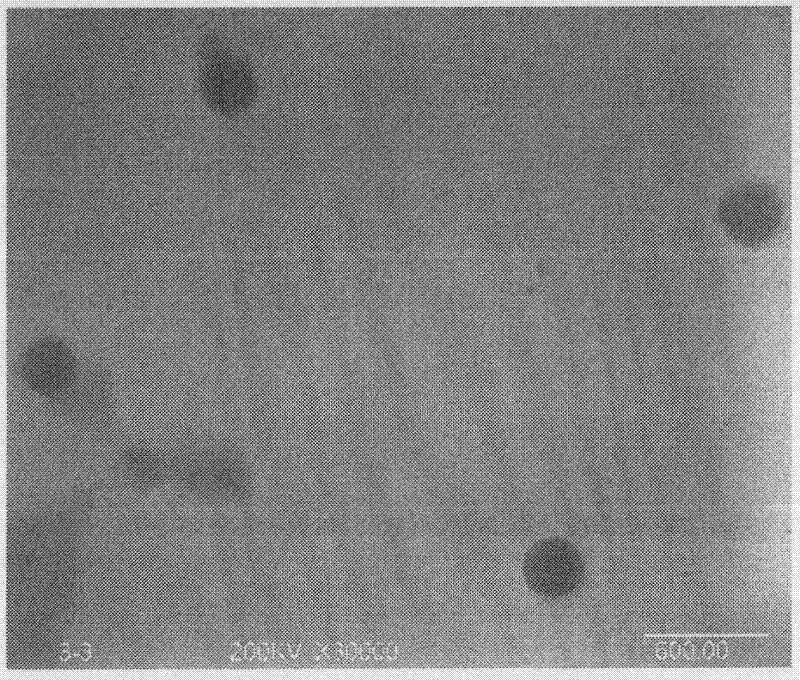

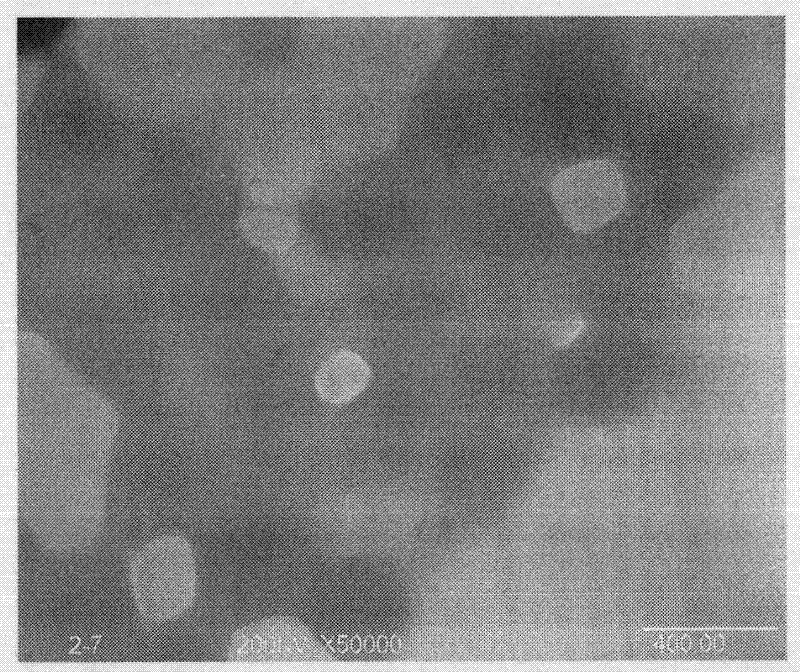

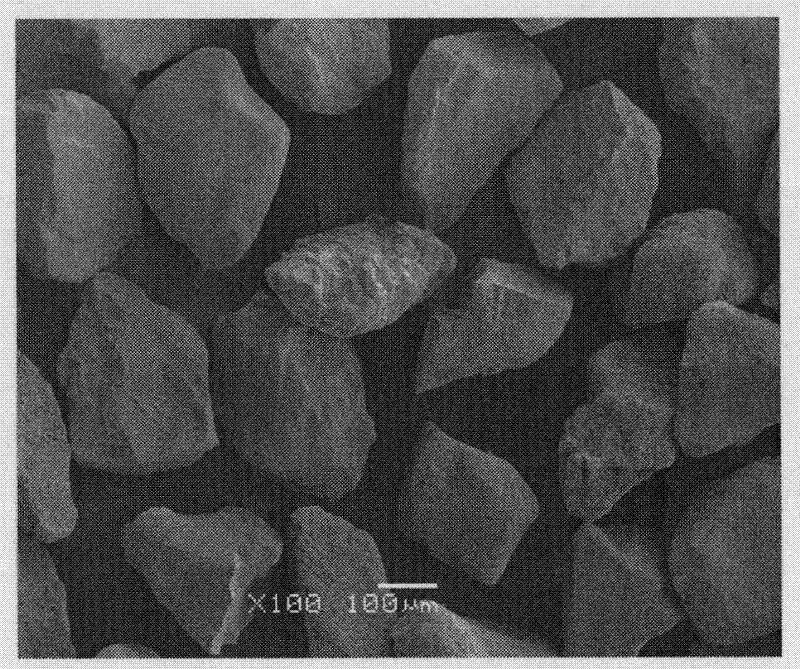

Image

Examples

Embodiment 1

[0027] a. to dissolve, to mix

[0028] Take 30 parts of deionized water and 1.05 parts of polyvinyl alcohol into the reactor, stir for 15 minutes, heat up to 85-90°C to make it almost completely dissolved, cool down to about 55°C, and then slowly add 20 parts of deionized water dissolved 0.9 parts of compound emulsifier, add 4 parts of vinyl acetate, and stir to make it fully mixed.

[0029] b. Pre-emulsification

[0030] After the mixed solution in the first step was vigorously stirred for 15 minutes, 2.5 parts of 2.4% ammonium persulfate solution was added, the temperature was raised to 60-65° C., and the reaction was carried out for 30 minutes.

[0031] c. Polymerization

[0032] When the mixed solution in the second step has blue light and less reflux, add the remaining 12 parts of vinyl acetate, all 8 parts of methyl methacrylate and 6 parts of butyl acrylate dropwise, and add 3-4 parts every 15 minutes. Drop the initiator and adjust the dropping speed to ensure that t...

Embodiment 2

[0034] a. to dissolve, to mix

[0035] Take 30 parts of deionized water and 1.05 parts of polyvinyl alcohol into the reactor, stir for 15 minutes, heat up to 85-90°C to make it almost completely dissolved, cool down to about 55°C, and then slowly add 20 parts of deionized water dissolved 0.12 parts of compound emulsifier, add 4 parts of vinyl acetate, and stir to make it fully mixed.

[0036] b. Pre-emulsification

[0037] After the mixed solution in the first step was vigorously stirred for 15 minutes, 2.5 parts of 2.4% ammonium persulfate solution was added, the temperature was raised to 60-65° C., and the reaction was carried out for 30 minutes.

[0038] c. Polymerization

[0039] When the mixed solution in the second step has blue light and less reflux, add the remaining 12 parts of vinyl acetate, all 8 parts of methyl methacrylate and 6 parts of butyl acrylate dropwise, and add 3-4 parts every 15 minutes. Drop the initiator and adjust the dropping speed to ensure that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com