Device for electrospinning three-dimensional controlled structure of nanofibers

An electrospun nanofiber, three-dimensional technology, applied in the field of electrospun nanofiber three-dimensional controllable structure device, can solve the problems of complex three-dimensional structure, low technical efficiency, and inaccessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

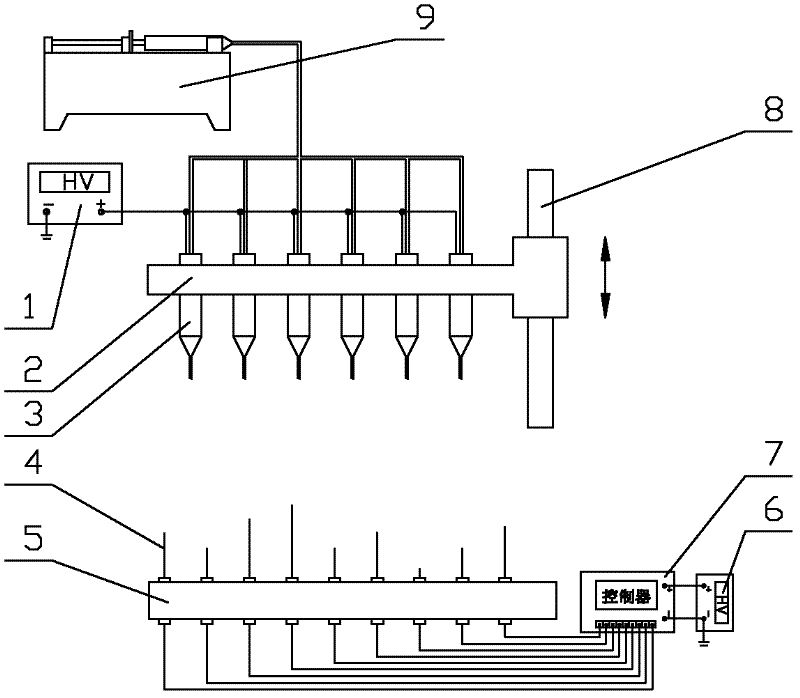

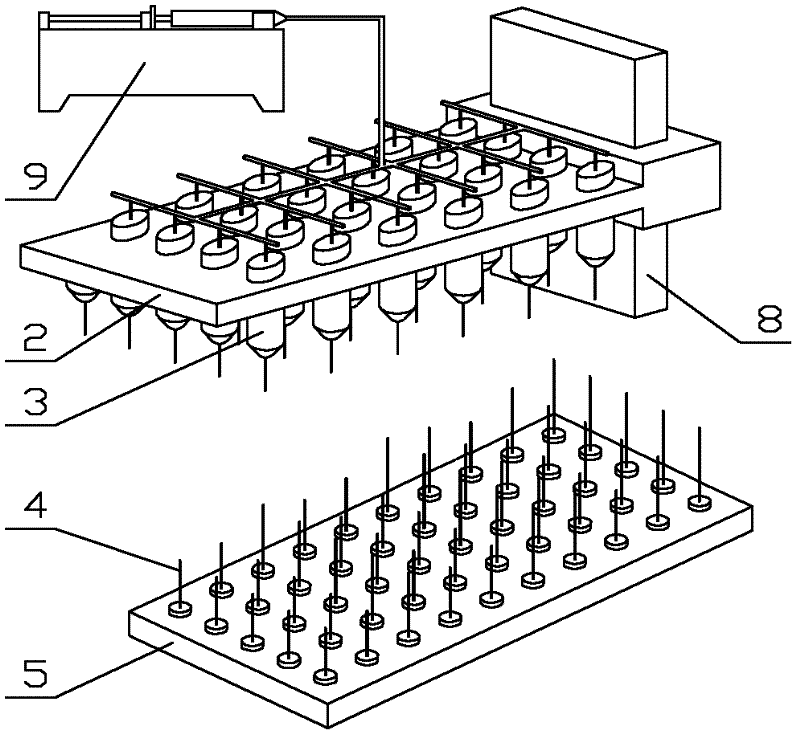

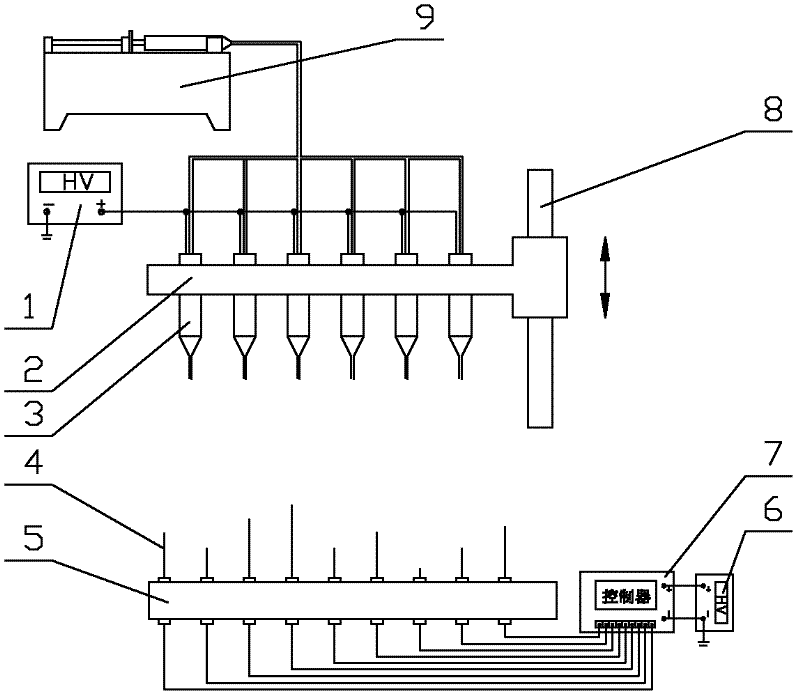

[0022] see figure 1 and 2 , the embodiment of the present invention is provided with DC high-voltage power supply 1, nozzle array support plate 2, spinning nozzle array 3, probe array 4, polytetrafluoroethylene insulating substrate 5 with equidistant holes, controller 6 (using single-chip microcomputer), Auxiliary DC high-voltage power supply 7, guide rail 8 and precision injection pump 9.

[0023]The positive pole of the DC high-voltage power supply 1 (30kV) is electrically connected to the spinning nozzle array 3, and the negative pole of the DC high-voltage power supply 1 is connected to the negative pole of the auxiliary DC high-voltage power supply 7 (10kV) and grounded. The precision syringe pump 9 communicates with the spinning nozzle array 3 through a plastic hose (delivery tube), and provides the spinning nozzle array 3 with a solution with a flow rate of 0.3-20 L / h. The distance between the nozzles of the spinneret array 3 and the polytetrafluoroethylene insulating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com