Reinforced solar cell module and making method thereof

A technology of solar cells and solar cells, applied in the field of solar energy, which can solve the problems of reduced output power of components, high temperature, and affecting power output of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the technical characteristics and content of the patent of the present invention, the detailed technical description of this patent is as follows in conjunction with the accompanying drawings:

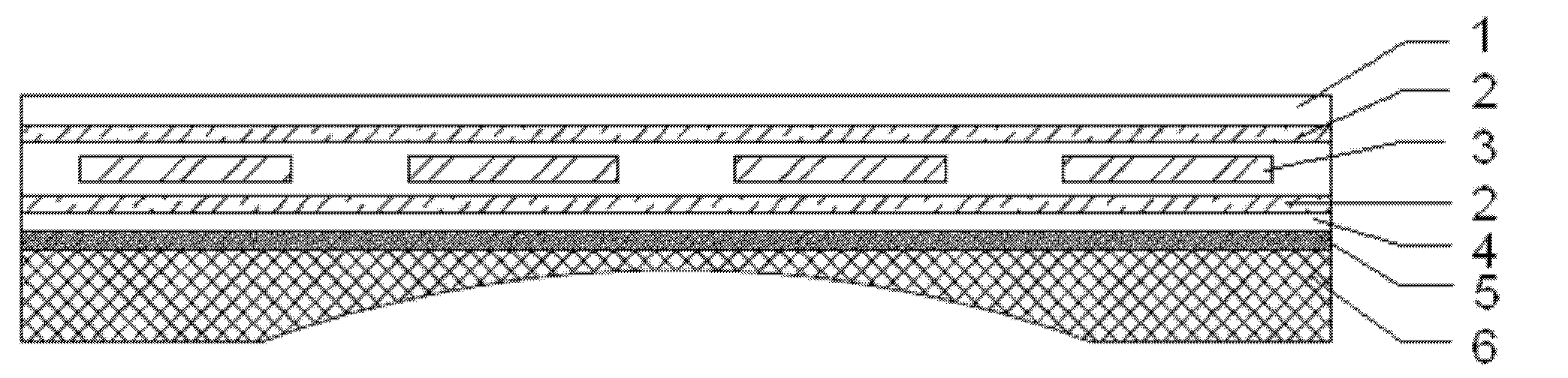

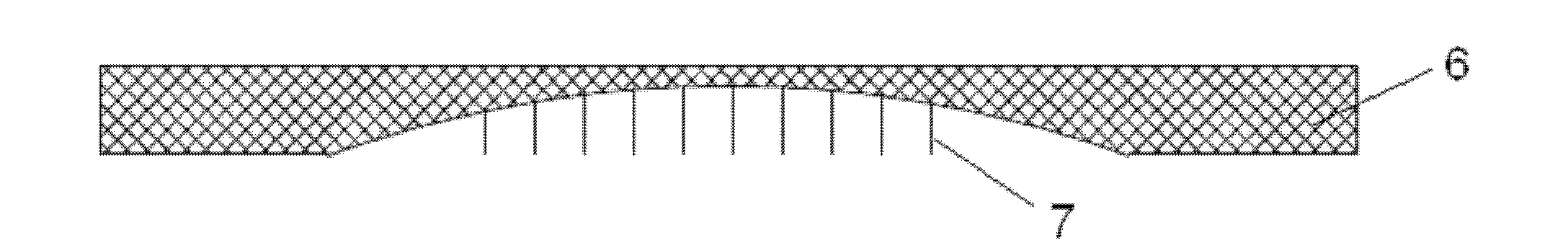

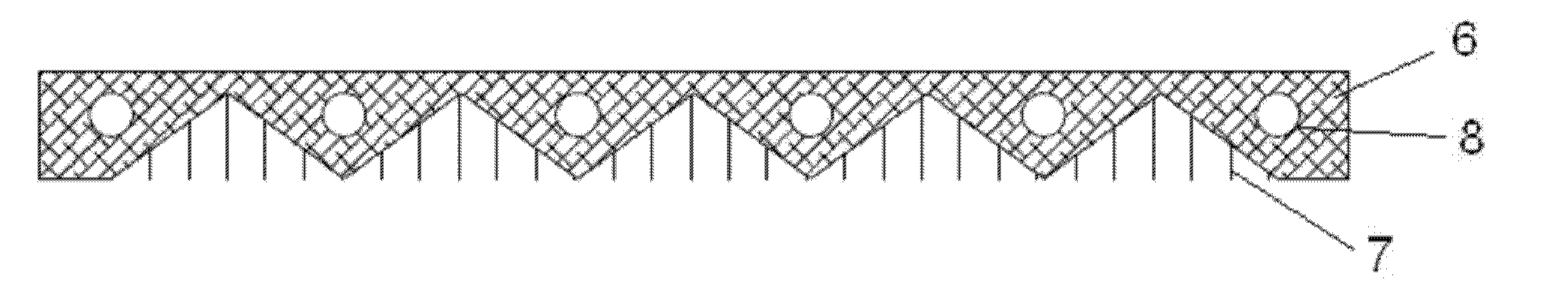

[0030] Such as figure 1 As shown, a reinforced solar cell assembly includes tempered glass 1, solar cells 3, and a back plate 4. There is an EVA layer 2 of encapsulation material, and a reinforcement component 6 is provided on the outside of the back plate 4, and the back plate 4 and the reinforcement component 6 are combined together through thermal conductive silica gel.

[0031] Among them, tempered glass 1 has high light transmittance and plays the role of protecting the solar cells, the packaging material EVA layer 2 has the function of sealing and bonding, and the back plate 4 has the ability of aging resistance, corrosion resistance, preventing water vapor penetration and good performance. Insulation performance, thermally conductive silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com