Phase change heat exchanger thermoelectric generation device

A technology of phase conversion heat exchanger and thermoelectric power generation, which is applied in the direction of generators/motors, thermoelectric device parts, electrical components, etc., can solve the problems of low power generation efficiency, and achieve simple structure, improved contact, waste heat utilization rate and power generation high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0016] Embodiments of the present invention are described as follows in conjunction with the accompanying drawings:

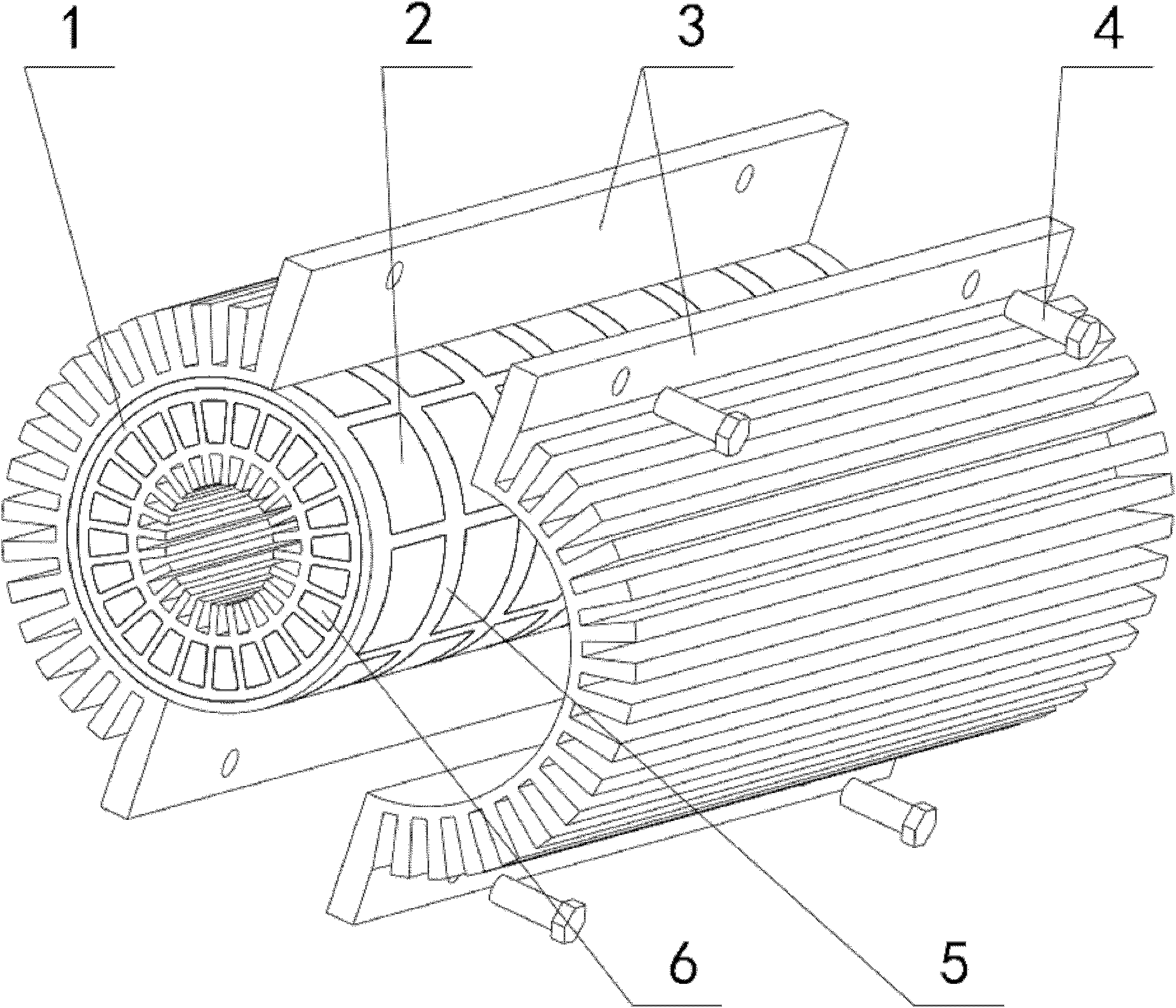

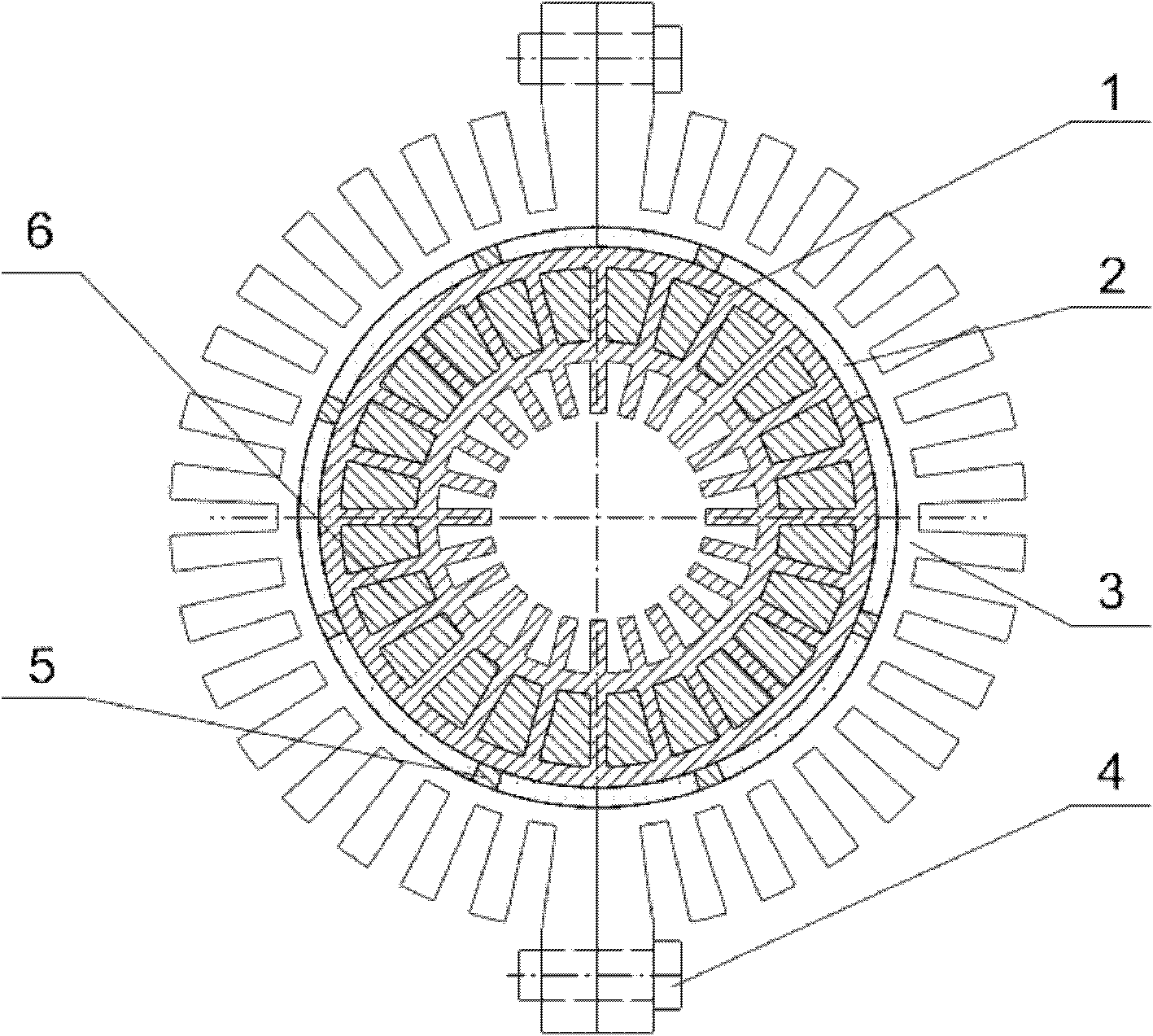

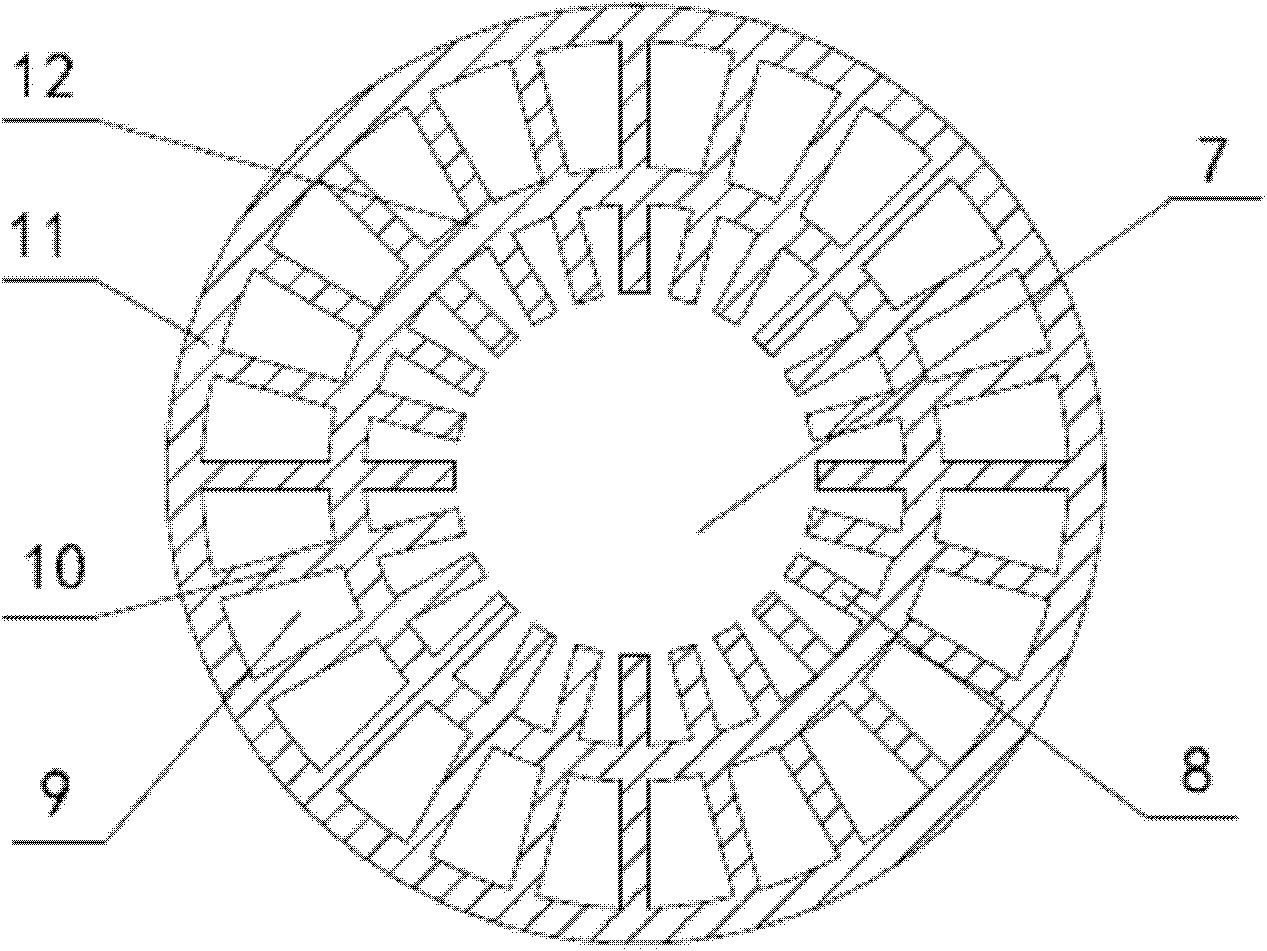

[0017] Such as figure 1 and figure 2 As shown, the present invention is composed of a phase-change heat exchanger 1, a semiconductor thermoelectric power generation sheet 2, a fin radiator 3, a connector 4, an insulating material 5 and a phase-change energy storage material 6, wherein the outer surface of the phase-change heat exchanger 1 Between the arc surface and the inner arc surface of the fin radiator 3, there are semiconductor thermoelectric power generation chips 2 connected in series or in series and parallel, and the semiconductor thermoelectric power generation chips 2 are in contact with the outer arc surface of the phase change heat exchanger 1 The surface of the semiconductor thermoelectric power generation sheet 2 is a high-temperature surface, and the surface of the semiconductor thermoelectric power generation sheet 2 in contact with the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com