Supercritical water jet cleaning equipment

A technology for supercritical water and cleaning equipment, which is applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. Effects of uniformity, improved cleaning repeatability and wafer-to- wafer uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

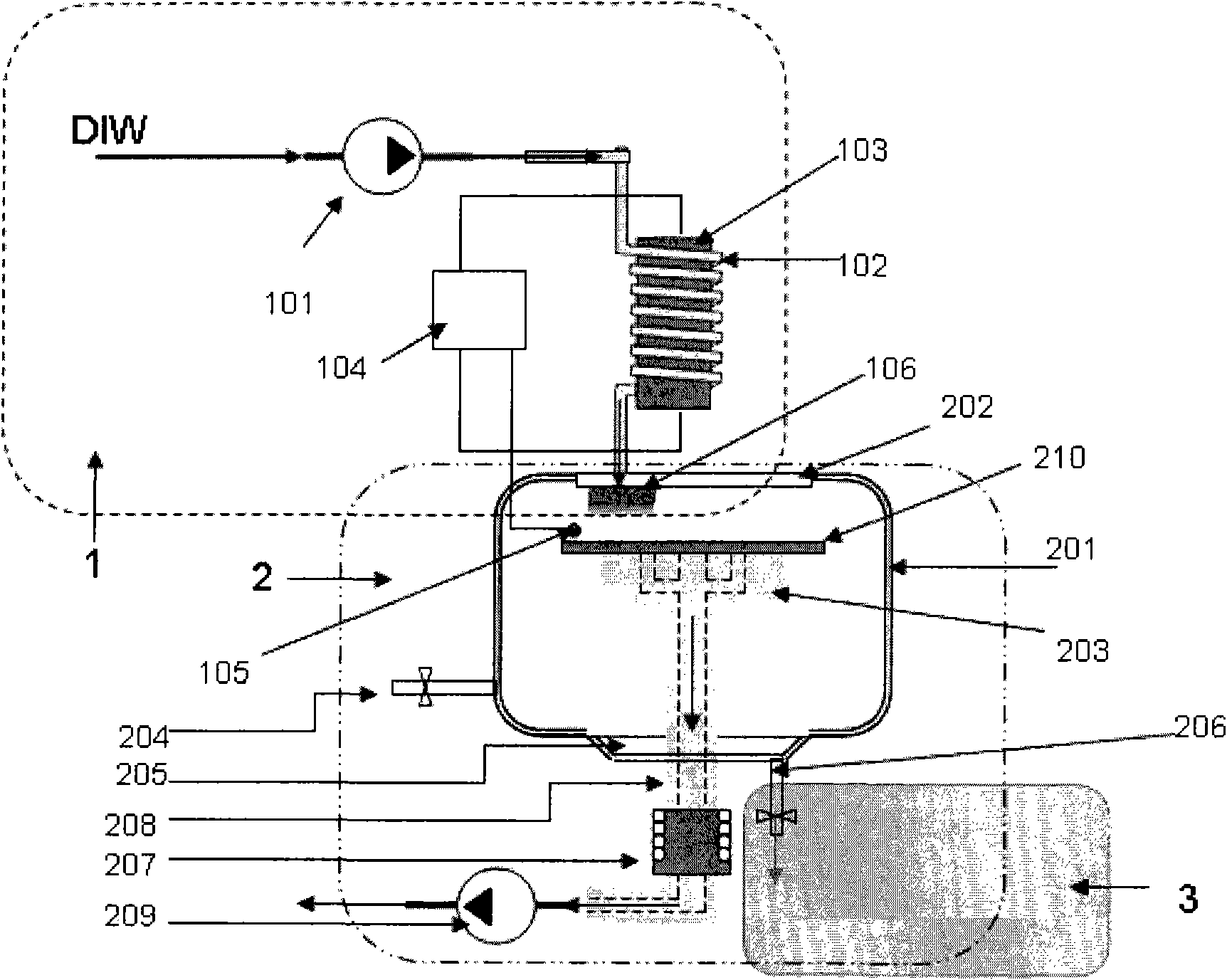

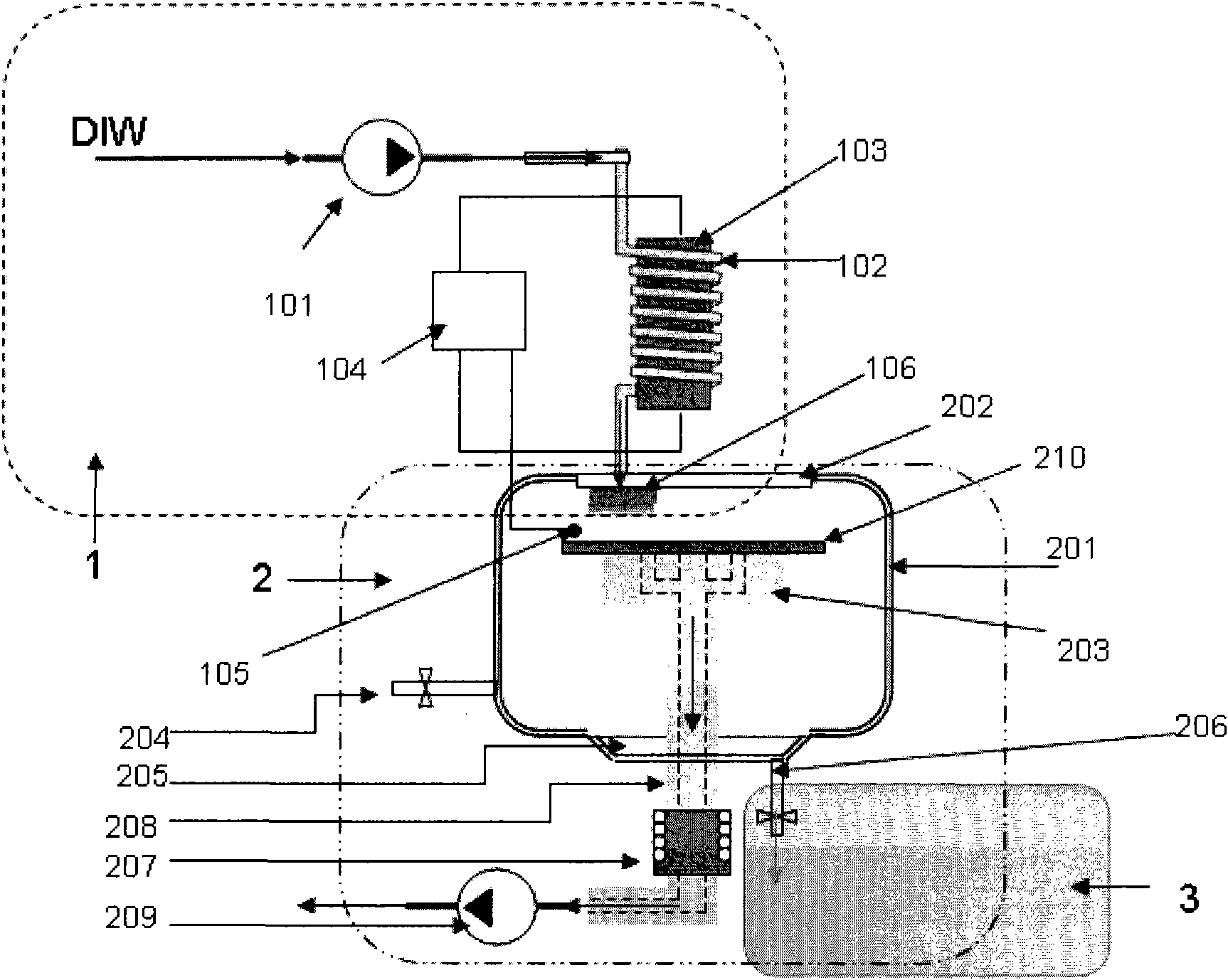

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the following takes the removal of photoresist on the surface of a silicon wafer as a specific example, and refers to the accompanying drawings to further describe the present invention in detail.

[0033] Such as figure 1 as shown, figure 1 Schematic diagram of the supercritical water jet cleaning equipment provided by the present invention, the equipment includes a supercritical water jet generation device 1, a cleaning chamber 2 and a cleaning product recovery treatment device 3, wherein the supercritical water in the supercritical water jet generation device 1 It reaches the silicon wafer in the cleaning chamber 2 in the form of a jet, and forms a supercritical water constant temperature and constant pressure microenvironment on the surface of the silicon wafer. Using the physical and chemical properties of supercritical water, it performs non-destructive cleaning on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com