Nanoscale electrode processing method based on AFM (atomic force microscopy)

An electrode processing and nano-electrode technology, which is applied in the fields of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of difficult to obtain cutting-edge electrodes, no records of nano-scale electrodes, and difficulty in meeting detection requirements for electrodes, and achieves easy operability. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

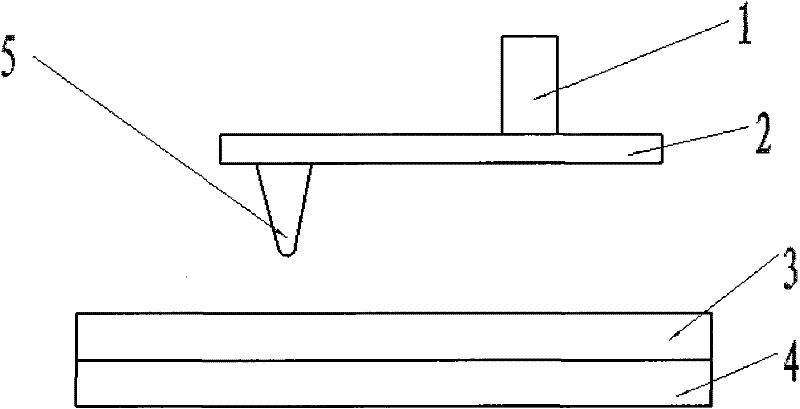

[0021] The working status of the present invention is as figure 1 As shown, 1 is PZT, 2 is AFM cantilever beam, 3 is gold electrode, 4 is silicon dioxide, and 5 is probe.

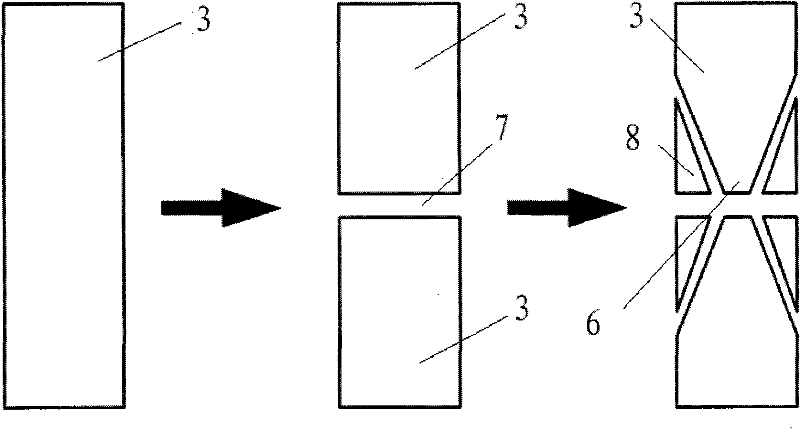

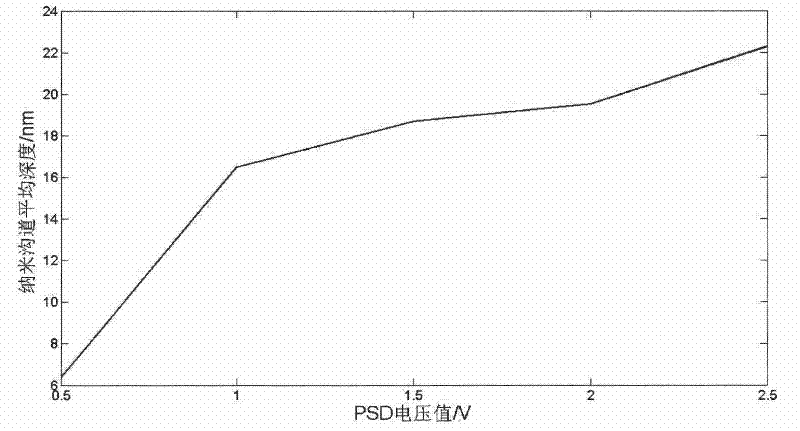

[0022] 1) Determine the relationship between cutting depth and PSD signal: as figure 1 , figure 2 As shown, the probe 5 processes a nano-channel 7 on the substrate, and at the same time divides the gold electrode 3 into a pair. In order to determine the cutting depth, it is first necessary to determine the relationship between the cutting depth and the PSD signal: for a silicon dioxide substrate in several Nano-channels with a certain depth are processed under different PSD voltage values (from small to large), and the processed nano-channels are scanned and imaged, and the depth values corresponding to different PSD signals are measured, and the fitting results are as follows: image 3 The graph of the relationship between voltage and depth is shown;

[0023] 2) Processing of nanochannels: Assuming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com