Method for recovering surfactant from soil washed liquid

A technology of surfactant and washing liquid, which is applied in the field of treating soil washing liquid and recovering surfactant, which can solve the problems of insufficient separation, troublesome liquid storage and disposal, etc., and achieve reduced treatment cost, good effect, and reduced sewage The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: the method for reclaiming surfactant from soil washing liquid

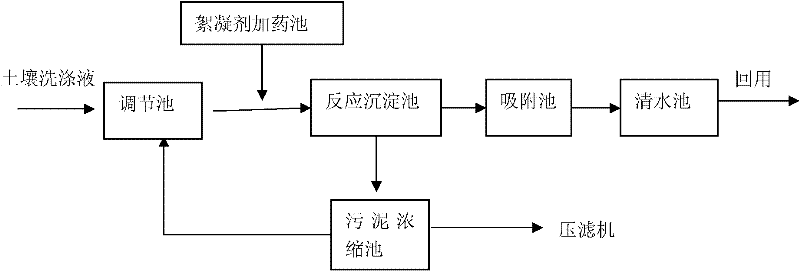

[0041] 1. Method (process such as figure 1 shown):

[0042] 1) After washing the soil with water containing surfactant TX100, precipitate, remove solid particles, recover the washed liquid, and obtain a soil washing liquid. Preliminary detection shows that the soil washing liquid contains 581.6 mg / L of surfactant and polycyclic aromatic hydrocarbons 0.507mg / L;

[0043] 2) The soil washing liquid is left to stand in the regulating tank until the water quality and quantity are stable, and the water surface is stable without ripples;

[0044] 3) Add cationic polyacrylamide (CPAM) accounting for 1% of the volume of the soil washing solution to the soil washing solution after standing, so that the flocculant and the soil washing solution are fully contacted and mixed to form a flocculent precipitate, and together with the sewage From flowing into the settling tank, leave standstill for 8 hours, ...

Embodiment 2

[0072] Embodiment 2: the method for reclaiming surfactant from soil washing liquid

[0073] 1, method, basically with embodiment 1, filtration rate is 18m / h.

[0074] 2, detection method is the same as embodiment 1;

[0075] 3. Results (see Table 3 and Table 4):

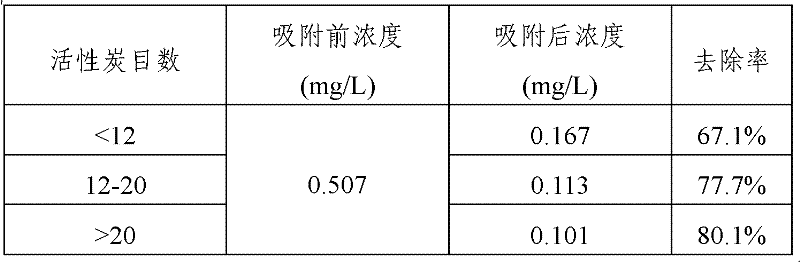

[0076] Table 3: Data before and after adsorption of polycyclic aromatic hydrocarbons (filtration rate is 18m / h)

[0077]

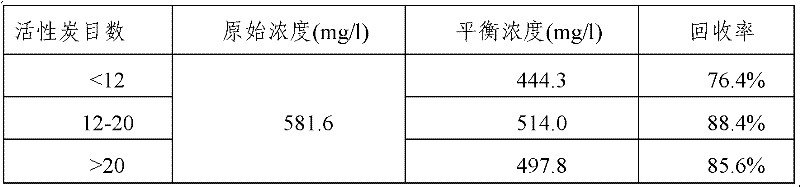

[0078] Table 4: Concentration values before and after adsorption of TX100 (filtration rate is 18m / h)

[0079]

[0080] After testing, it was found that:

[0081] 1) Removal rate of polycyclic aromatic hydrocarbons: when the filtration speed is 18m / h, the removal rate of polycyclic aromatic hydrocarbons is 72.8% when filtered with less than 12 mesh activated carbon; the removal rate of polycyclic aromatic hydrocarbons is 84% when filtered with 12-20 mesh activated carbon ;Filtered with activated carbon larger than 20 mesh, the removal rate of polycyclic aromatic hydrocarbons is 86%; ...

Embodiment 3

[0083] Embodiment 3: the method for reclaiming surfactant from soil washing liquid

[0084] 1, method, basically with embodiment 1, filtration rate is 24m / h.

[0085] 2, detection method is the same as embodiment 1;

[0086] 3. Results (see Table 5 and Table 6):

[0087] Table 5: Data before and after adsorption of polycyclic aromatic hydrocarbons (filtration rate is 24m / h)

[0088]

[0089] Table 6: Concentration values before and after adsorption of TX100 (filtration rate is 24m / h)

[0090]

[0091] After testing, it was found that:

[0092] 1) Removal rate of polycyclic aromatic hydrocarbons: when the filtration speed is 24m / h, the removal rate of polycyclic aromatic hydrocarbons is 71.4% when filtered with less than 12 mesh activated carbon; the removal rate of polycyclic aromatic hydrocarbons is 79% when filtered with 12-20 mesh activated carbon ;Filtered with activated carbon larger than 20 mesh, the removal rate of polycyclic aromatic hydrocarbons is 82%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com