Ultraviolet light solidified antistatic organosilicon separant

A silicon release agent and anti-static technology, applied in the direction of coating, etc., can solve the problems of low production efficiency, environmental pollution, high cost, etc., and achieve the effects of improving production efficiency, reducing pollution, and reducing product pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

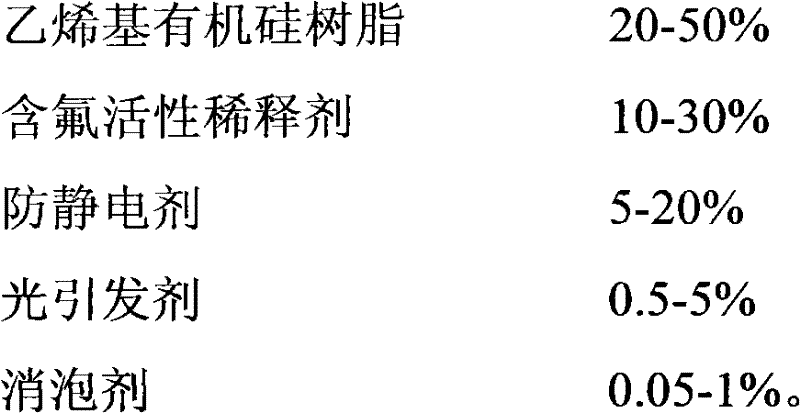

Method used

Image

Examples

Embodiment 1

[0018] Add 25g of hexafluorobutyl acrylate to the agitator, start the high-speed dispersing disc at 500rpm, then add 63g of γ-methacryloxypropyltrimethoxysilane-terminated polysiloxane resin, 10g of antistatic agent, 2g Photoinitiator 1173 / 184 (ratio 1:1) 0.2g defoamer BYK333, after all the materials are added, adjust the speed to 2500rpm, disperse at high speed for 3 hours, filter the material with a 300-mesh nylon mesh.

[0019] The release agent is coated on a 0.025 micron thick PET polyester film by a coater, cured with a 365nm ultraviolet lamp, the curing energy is 80-120mJ / cm2, and the dry film thickness after curing is about 1 micron. Perform performance tests such as anti-static, peeling force, and adhesion.

Embodiment 2

[0021] Add 25g of hexafluorobutyl acrylate into the agitator, start the high-speed dispersion disc at 500rpm, then add 58g of γ-methacryloxypropyltrimethoxysilane-terminated polysiloxane resin, 15g of antistatic agent, 2g Photoinitiator 1173 / 184 (ratio 1:1) 0.2g defoamer BYK333, after all the materials are added, adjust the speed to 2500rpm, disperse at high speed for 3 hours, filter the material with a 300-mesh nylon mesh.

[0022] The release agent is coated on a 0.025 micron thick PET polyester film by a coater, cured with a 365nm ultraviolet lamp, the curing energy is 80-120mJ / cm2, and the dry film thickness after curing is about 1 micron. Perform performance tests such as anti-static, peeling force, and adhesion.

Embodiment 3

[0024] Add 25g of hexafluorobutyl acrylate into the agitator, start the high-speed dispersion disc at 500rpm, then add 53g of γ-methacryloxypropyltrimethoxysilane-terminated polysiloxane resin, 20g of antistatic agent, 2g Photoinitiator 1173 / 184 (ratio 1:1) 0.2g defoamer BYK333, after all the materials are added, adjust the speed to 2500rpm, disperse at high speed for 3 hours, filter the material with a 300-mesh nylon mesh.

[0025] The release agent is coated on a 0.025 micron thick PET polyester film by a coater, cured with a 365nm ultraviolet lamp, the curing energy is 80-120mJ / cm2, and the dry film thickness after curing is about 1 micron. Perform performance tests such as anti-static, peeling force, and adhesion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com