Atmosphere controlled quenching device for magnetically buffering fall of furnace body

A technology of quenching device and furnace body, which is applied in the direction of quenching device, manufacturing tools, heat treatment equipment, etc., which can solve problems such as difficult to achieve, slow quenching cooling rate, and failure to meet requirements, and achieve the effect of reducing impact and high quenching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

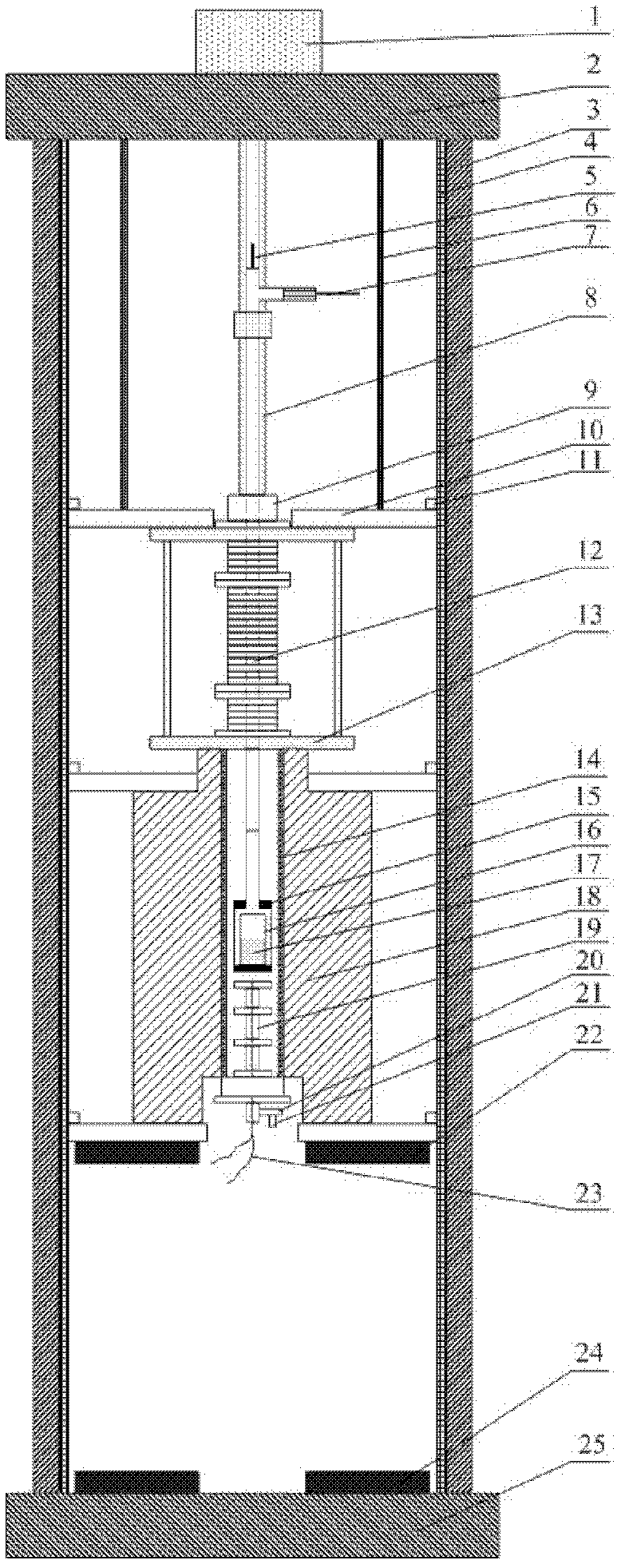

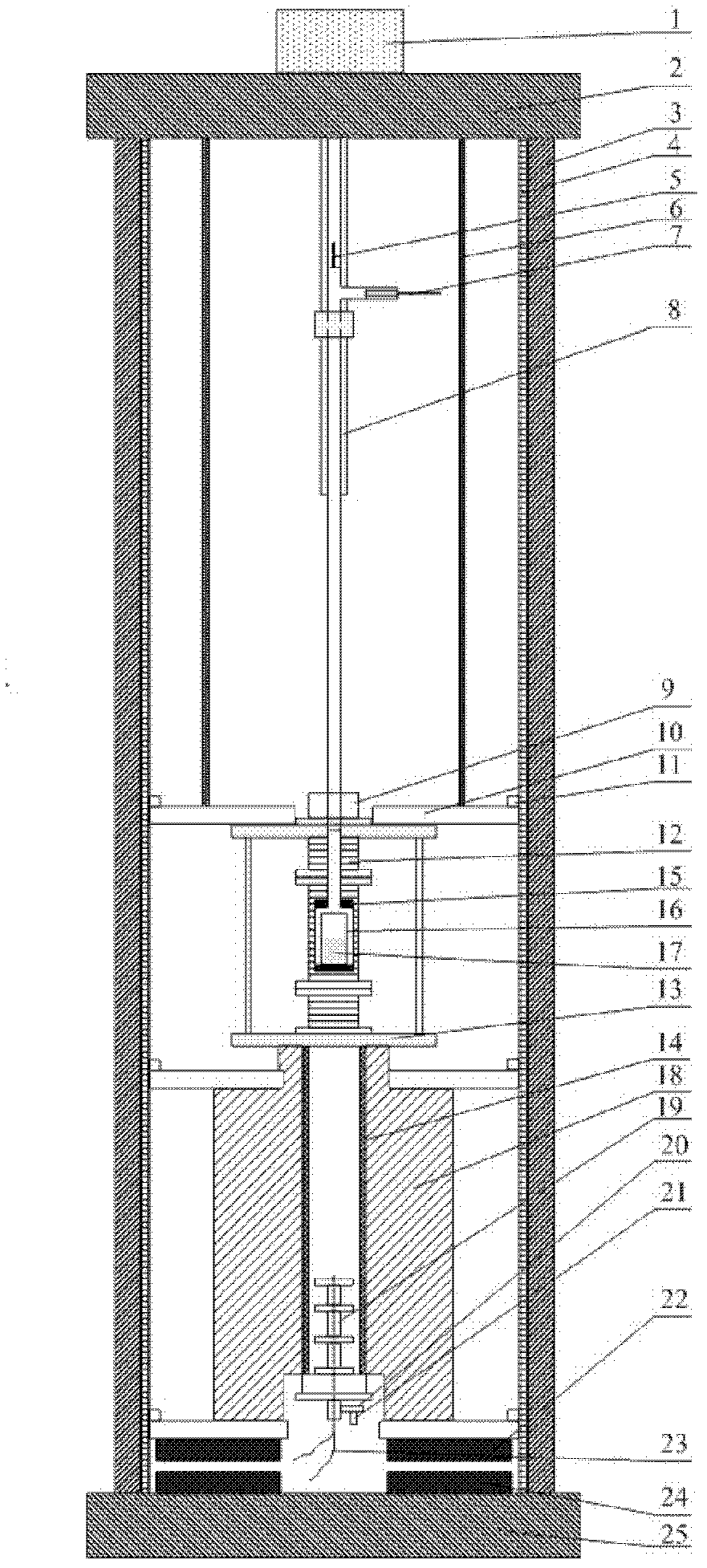

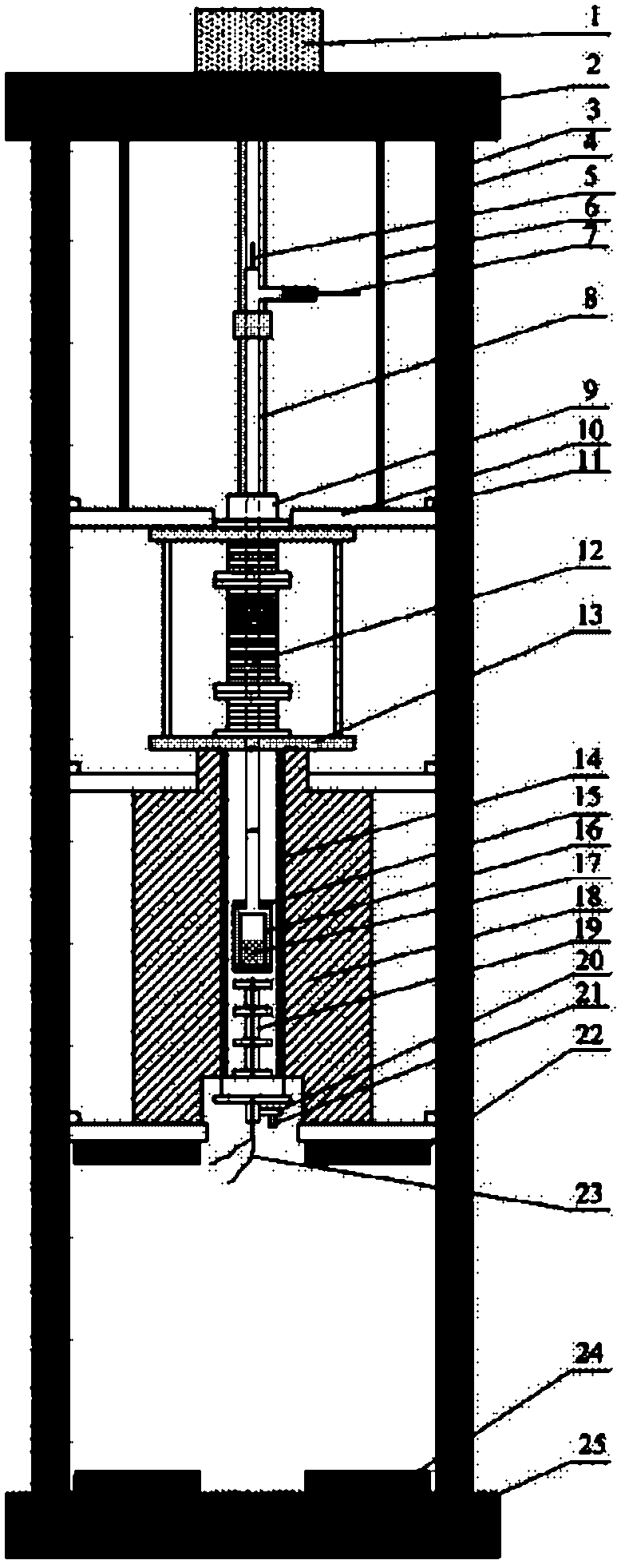

[0024] The present invention provides an atmosphere-controlled quenching device for magnetically buffering the fall of the furnace body, which includes three sets of fixed support plates 10 placed on the vertical guide rail 4 through guide shoes 11, and the three sets of fixed support plates 10 are respectively fixed A body of furnace 18 and the cooling chamber 12 connected thereto are provided. And in order to make the relative position of cooling chamber and body of heater move up and down on track fixed and sealing connection, add fixed support 13 at the upper and lower ends of cooling chamber 12 deliberately. The body of furnace 18 and the water-cooled cooling chamber 12 can move up and down, and its integral upward movement is completed by the traction machine 1 placed on the top 2 of the cabinet through the traction steel wire 6 . Since the traction machine 1 needs to bear a relatively large weight, the outer wall 3 of the chassis carrying the top 2 of the chassis needs ...

Embodiment 2

[0037] In the following, the application of the invention will be further described in conjunction with the determination of the distribution balance of vanadium in slag and metallic copper.

[0038] First body of heater 18 and water-cooled cooling chamber 12 are lowered to the lowest position as attached figure 2 location shown. The three-stage cooling chamber 12 is opened. The Mo test crucible 16 loaded in the metal Mo hanging basket 15 and the sample high-purity metal copper sheet heated with the furnace and the oxide 17 mixed and pressed in the proportion of slag. The cooling chamber 12 is then installed. The vanadium oxide that needs to be fed at high temperature is compressed into a tablet and loaded into the sampler 7 . Start traction machine 1, body of heater 18 and water-cooled cooling chamber 12 are risen to highest position as attached figure 1 shown. Hanging basket 15, crucible 16 and the sample 17 that heats up with furnace are just in time in the isothermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com