Continuous countercurrent catalytic oxidation device of ventilation air gas of coal mine

A catalytic oxidation and wind gas technology, applied in gas emission, safety devices, mining equipment and other directions, can solve the problems of increasing system complexity, affecting the stable operation of the device, difficult maintenance, etc. Reduces the effect of airflow reversing systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

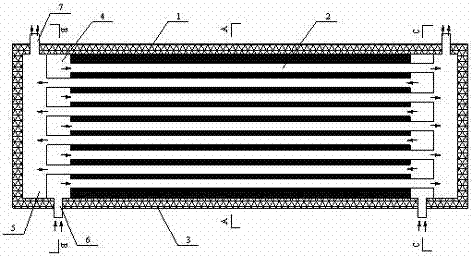

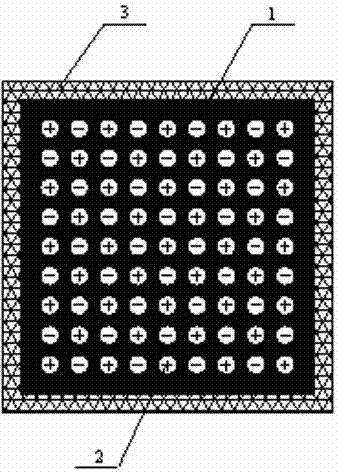

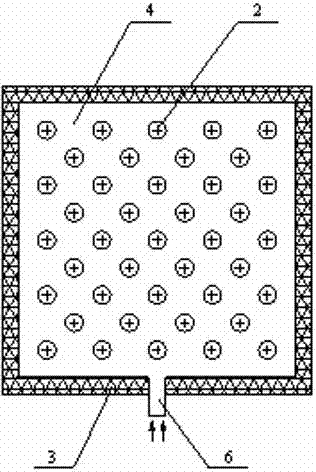

[0016] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a continuous countercurrent catalytic oxidation device for exhaust gas in coal mines is composed of a ceramic regenerator 1, a circular channel 2, an insulating material 3, an air intake chamber 4, an exhaust chamber 5, an air intake pipe 6 and an exhaust pipe 7 Composition, the ceramic regenerator 1 is located in the center of the whole device, the two ends of the ceramic regenerator 1 are provided with an air intake chamber 4 and an exhaust chamber 5, and the circular channel 2 is along the length direction of the ceramic regenerator 1 Evenly arranged in it, the air intake chamber 4 is located at both ends of the circular passage 2 communicating with it, the air intake pipe 6 at both ends of the bottom communicates with the air intake chamber 4, and the exhaust chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com