Device and method for monitoring and controlling security risk of turbine bearing in on-line manner

A technology for safety risks and steam turbines, applied in the field of steam turbines, can solve the problems of online monitoring and control of safety risks of steam turbine bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

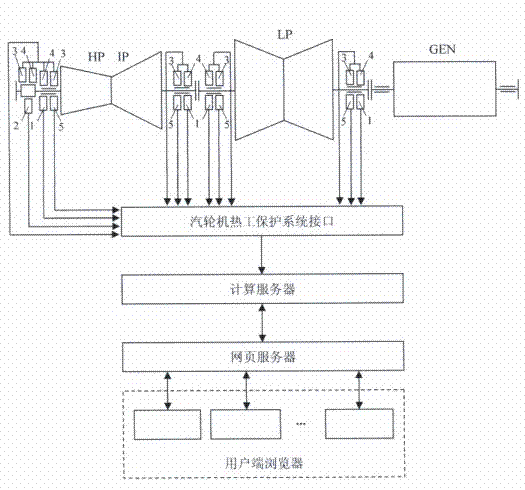

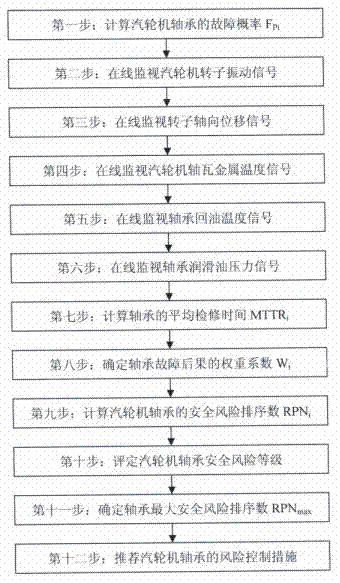

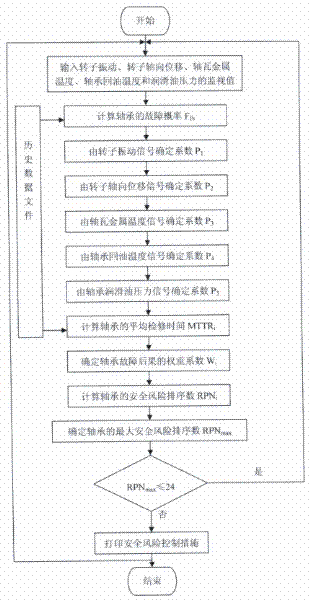

[0051] like figure 1 As shown, the block diagram of the online monitoring and control method of the steam turbine bearing safety risk of the present invention, the online monitoring and control device of the steam turbine bearing safety risk of the present invention is composed of a vibration sensor 1, an axial displacement sensor 2, a bearing metal temperature sensor 3, and a bearing return oil temperature. Sensor 4, bearing lubricating oil pressure sensor 5, steam turbine thermal protection system interface, computing server, web server and client browser. The thrust bearing on the side of the high and medium pressure rotor governor is provided with an axial displacement sensor 2, a Bearing metal temperature sensor 3 and a bearing return oil temperature sensor 4, radial bearing on the side of high and medium pressure rotor governor, radial bearing on the side of high and medium pressure rotor generator, radial bearing on the side of low pressure rotor governor and low pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com