Energy-saving silencer

A noise reduction and noise reduction technology, applied in the field of mufflers, can solve problems such as narrow frequency band of noise reduction, achieve the effects of reducing fuel consumption, solving noise reduction and transmission loss, and reducing noise emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

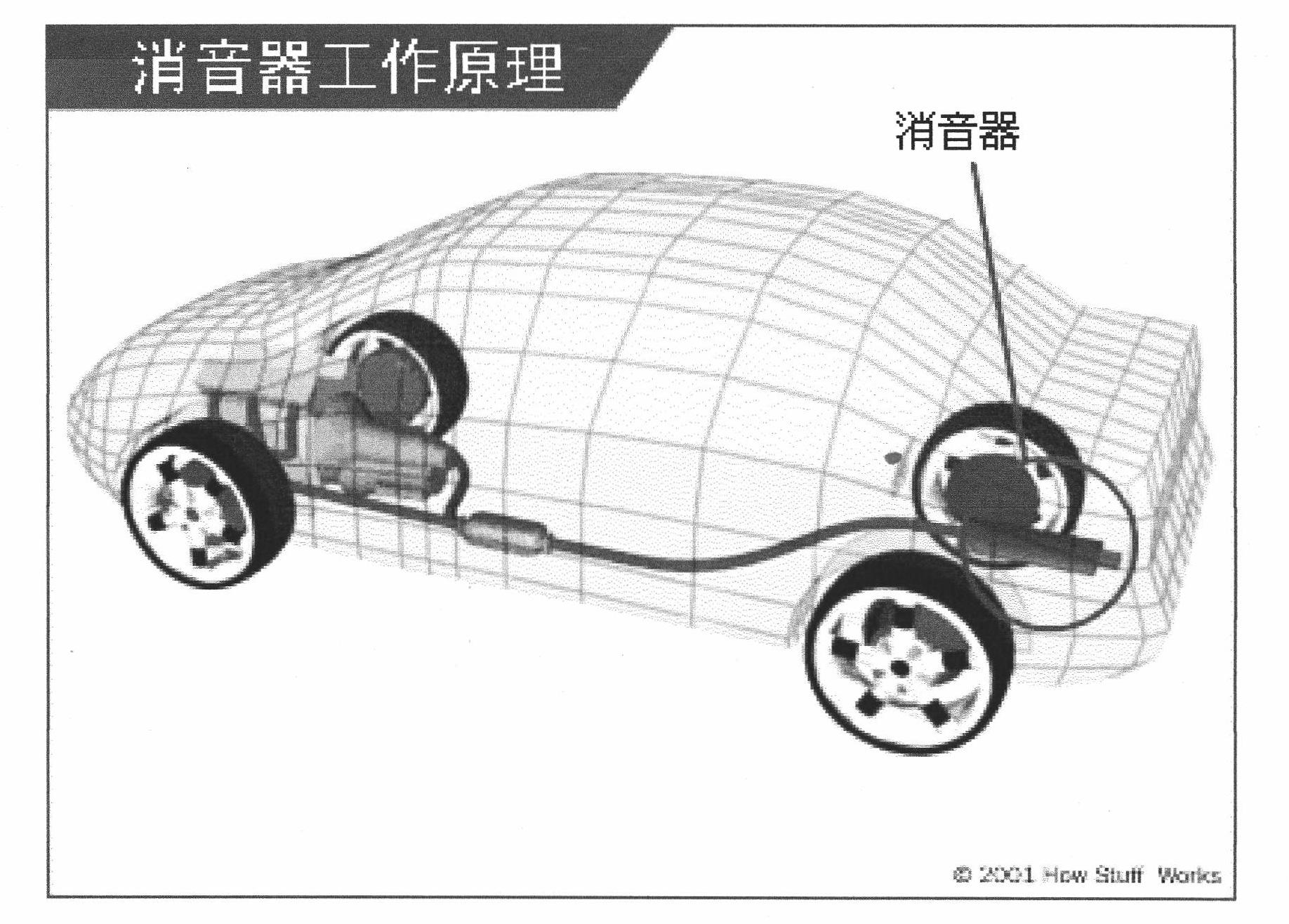

[0042] Such as Figure 11 :

[0043] 1. When the engine exhaust gas is discharged ( Figure 11 10 and 11 in the example), directly hitting the wind rotor blades with a certain twist angle to drive the wind rotor blades to rotate, directly plays a significant effect of comprehensive noise reduction of anti-elimination and resistance elimination.

[0044] 2. When one or more groups of through-holes on the wind rotor blades work continuously, the exhaust gas flow produces a Helmholm resonance effect in this confined space, which has the effect of shock absorption, noise reduction and energy saving.

[0045] 3. Helmholtz resonance principle explains Helmholtz resonator "Resonance tube" is a general term for Helmholtz resonators (it is named after Herman von Helmholtz (1821-1894), an authoritative scientist in this field Its name. Its design principle is very simple. A large box with a small opening will resonate at a certain frequency. Multi-stroke engines also produce sound wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com