Compression type exhaust gas self cooling system

A cooling system and compression technology, applied in the field of thermal energy and power, can solve the problems of exhaust energy loss, dissipation, bulky volume, etc., and achieve the effect of eliminating emissions and high-efficiency gas-phase closed cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

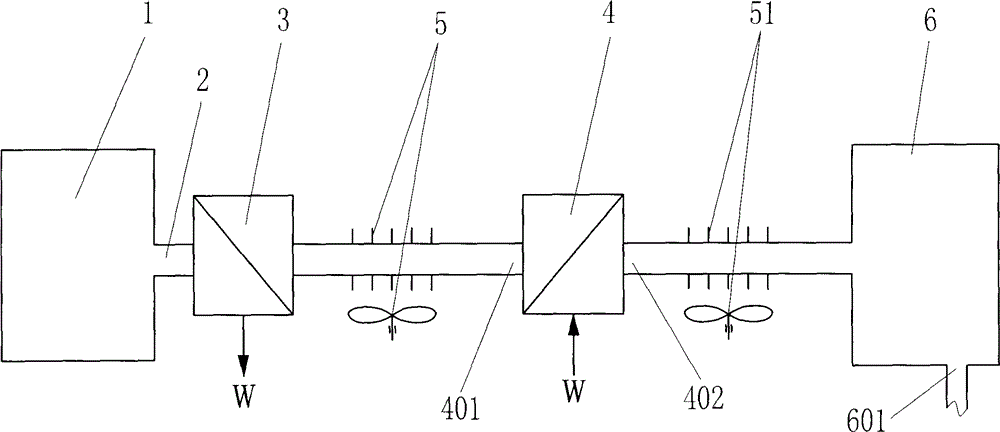

[0036] Such as figure 1 The compressed exhaust self-cooling system shown includes a thermodynamic system 1, a thermodynamic system exhaust duct 2, an exhaust thermodynamic unit 3, a compressor 4, a first heat exhauster 5, a second heat exhauster 51 and The expansion unit 6, the thermal power system exhaust channel 2 of the thermal power system 1 communicates with the air inlet of the exhaust thermal power unit 3, and the exhaust port of the exhaust thermal power unit 3 communicates with the cooled gas of the first heat exhauster 5 The inlet is communicated, the cooled gas outlet of the first heat exhauster 5 is communicated with the compressor inlet 401 of the compressor 4, the compressed gas outlet 402 of the compressor 4 is communicated with the cooled gas inlet of the second heat exhauster 51, and the first The cooled gas outlet of the second heat removal device 51 communicates with the air inlet of the expansion unit 6 , and the exhaust heat power unit 3 outputs power to t...

Embodiment 2

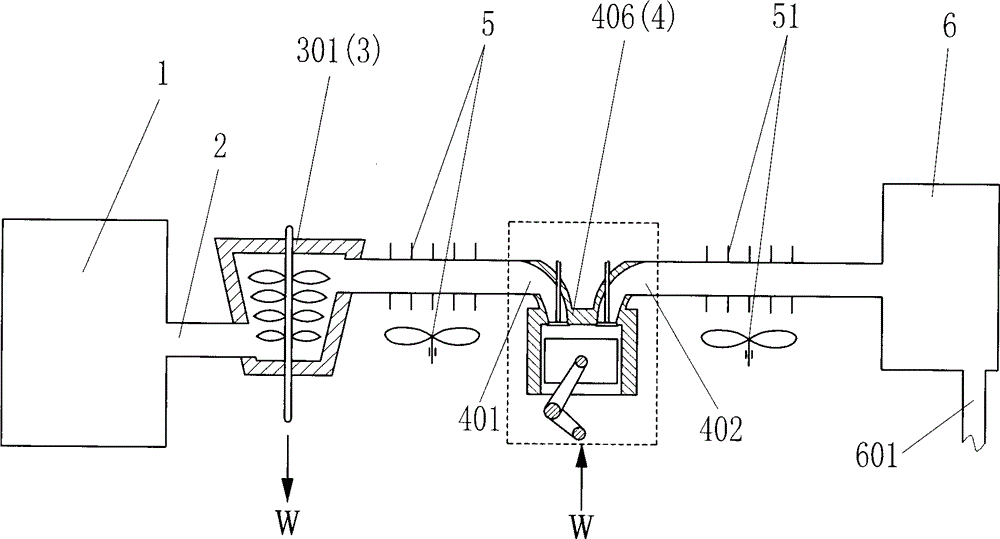

[0038] Such as figure 2The difference between the compressed exhaust self-cooling system shown in Embodiment 1 is that the exhaust heat power unit 3 is set as a power turbine 301, and the exhaust gas in the exhaust passage 2 of the heat power system passes through the power turbine 301 to the outside. After working to cool down, the first heat exhauster 5 exhausts and cools down, and then enters the air inlet 401 of the compressor. The compressor 4 is a piston compressor 406 . The expansion unit 6 is provided with a cold gas liquid-solid outlet 601 .

Embodiment 3

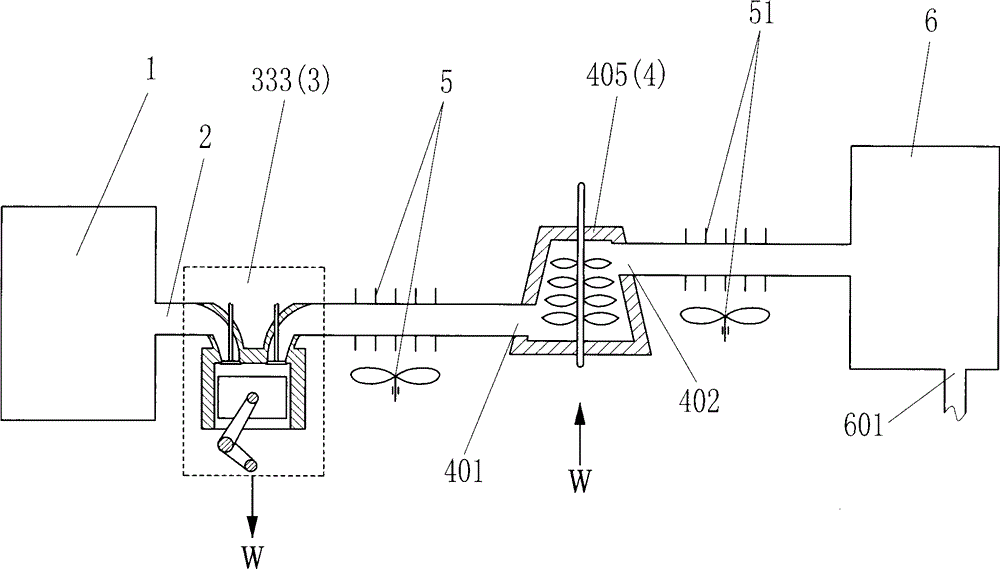

[0040] Such as image 3 The difference between the compressed exhaust self-cooling system shown in Embodiment 2 is that the exhaust thermal power unit 3 is set as a piston-type working mechanism 333, and the exhaust gas in the exhaust passage 2 of the thermal power system passes through the piston-type working mechanism. The power mechanism 333 works externally to cool down and then enters the air inlet 401 of the compressor after the first heat exhauster 5 exhausts heat and cools down. The compressor 4 is a turbo compressor 405 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com