Plunger hydraulic motor with automatical initiative input and driven state switchover

A hydraulic motor, plunger type technology, applied in the direction of variable capacity engine, machine/engine, reciprocating piston engine, etc., can solve the problems of increasing rotor resistance, turbulence, waste of energy, etc., to reduce resistance, reduce internal Loss and burden reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

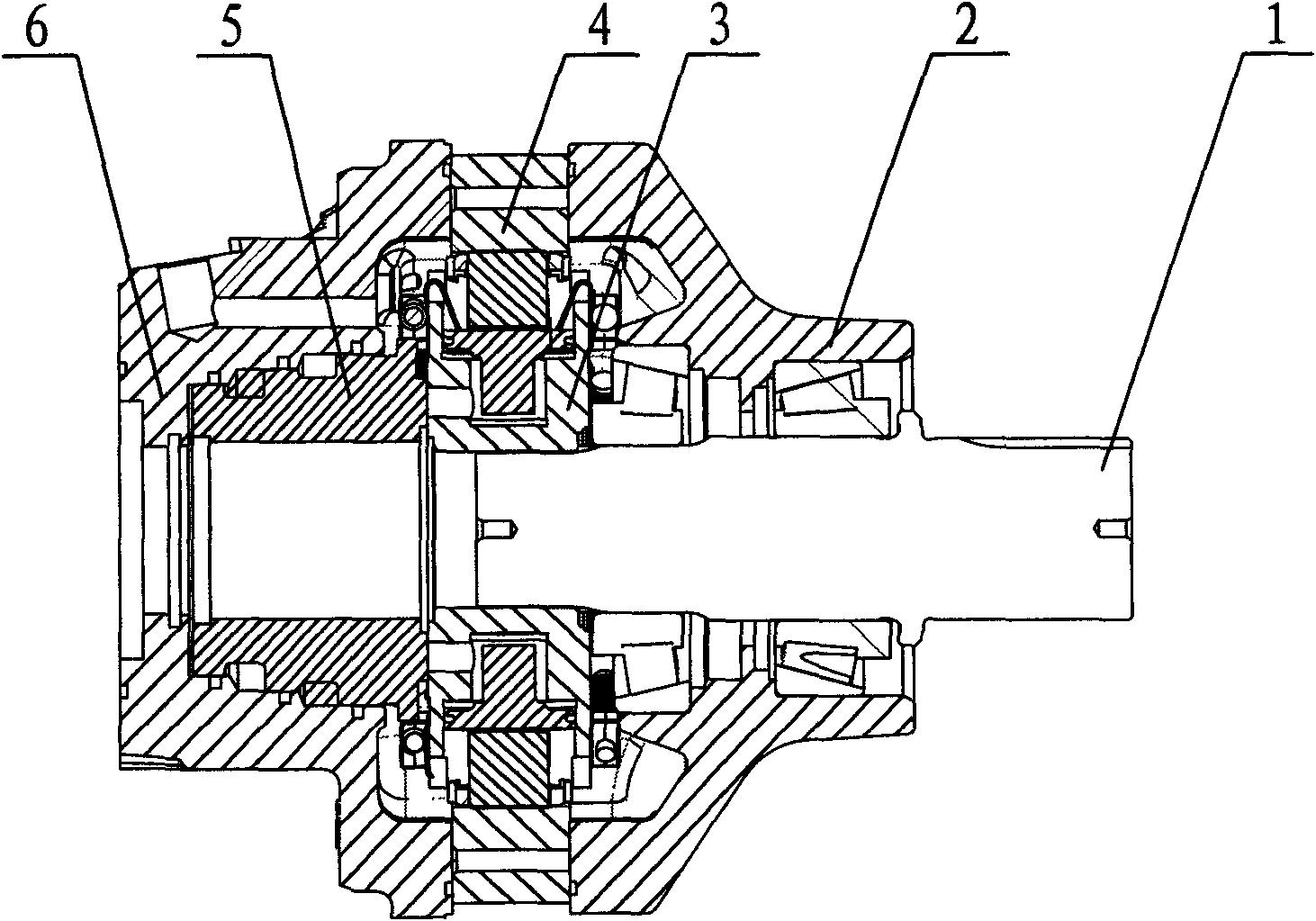

[0022] A plunger hydraulic motor, such as figure 1 As shown, it includes a front cover 2 , a rear cover 6 , a flow plate 5 , a stator 4 , a rotor 3 and a shaft 1 . The rear cover, distribution plate and stator are fixedly connected by bolts, the rotor is fixed on the upper rotating shaft, and the rotating shaft is connected to the front cover and rear cover through bearings, and then the front cover, stator, distribution plate and rear cover are fixed by bolts .

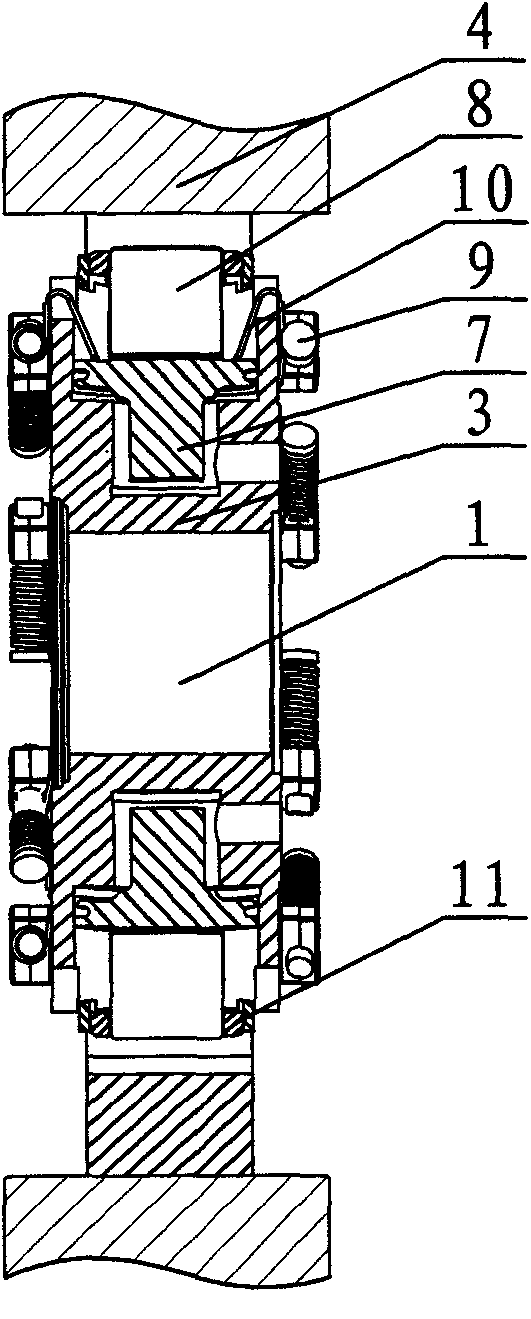

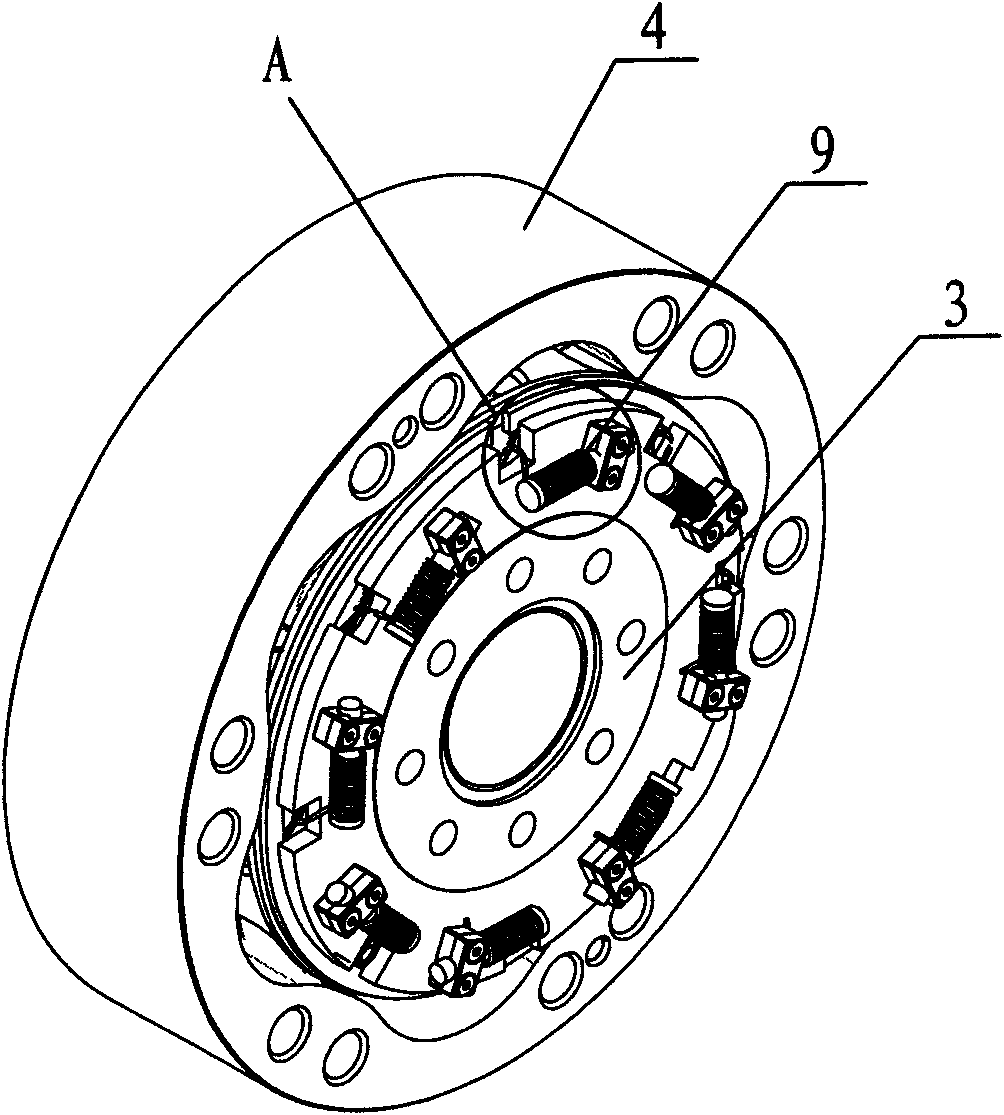

[0023] Such as figure 2 , image 3 , Figure 4 As shown, eight plunger holes 31 are evenly distributed on the rotor 3 , and a plunger 7 is installed in the plunger hole 31 , and the top of the plunger 7 is rotatably connected with the roller 8 . A retaining ring 11 is also installed on the plunger hole 31 to reduce the shaking when the roller 8 rotates.

[0024] There are also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com