USB (Universal Serial Bus)-based communication module and communication method for alternating current servo driver

A technology of servo driver and communication module, applied in the field of computer communication, can solve the problems of complicated servo system, low transmission rate, insufficient real-time performance, etc., so as to save the cost of construction and maintenance, reduce cost and complexity, and meet real-time performance. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

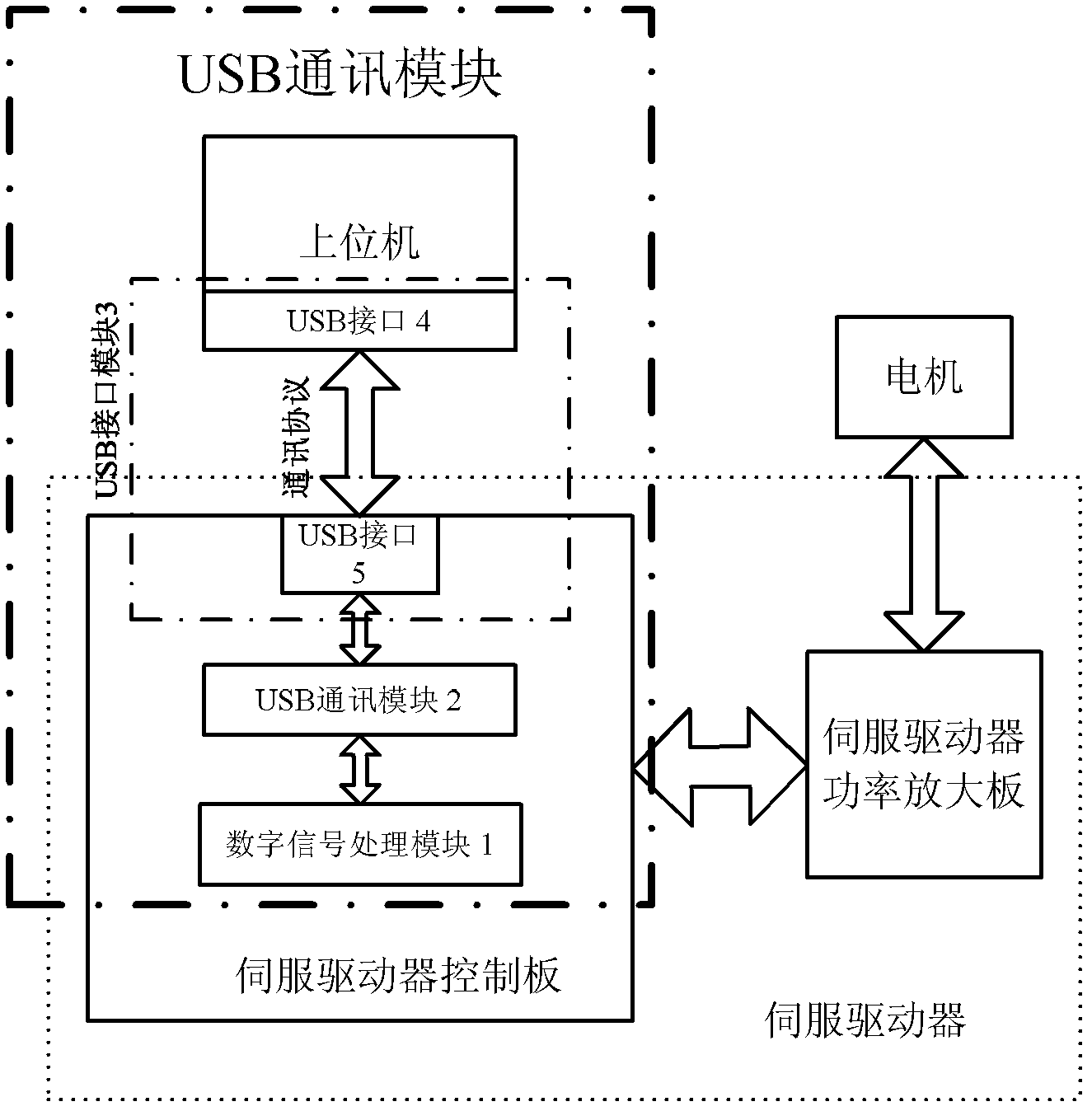

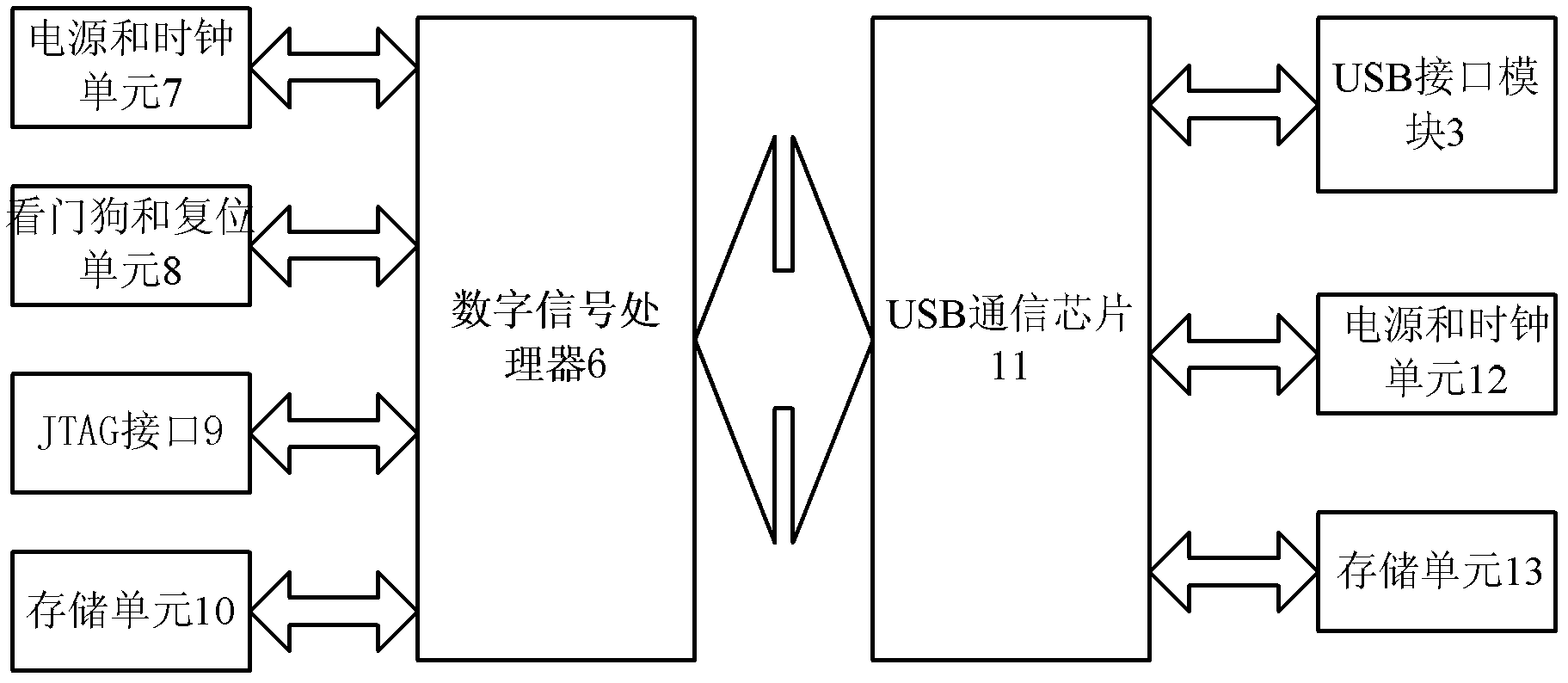

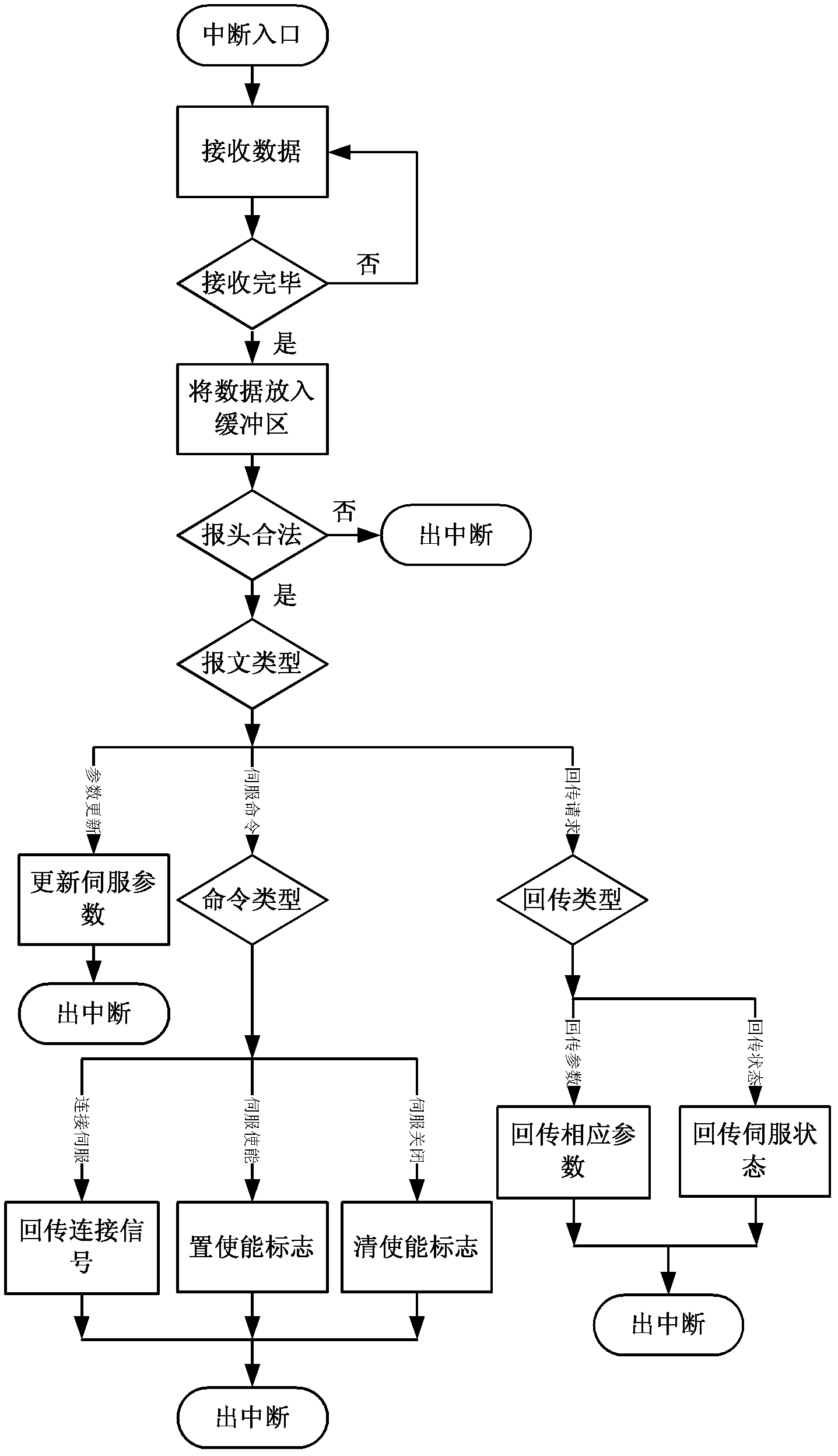

[0038] Such as figure 1 As shown, the USB-based AC servo driver communication module involved in this embodiment includes: a digital signal processing module 1, a USB communication module 2 and a USB interface module 3, wherein: the data of the digital signal processing module 1 and the USB communication module 2 The bus is connected and transmits the message information between the host computer and the servo drive to the USB communication module 2 in parallel. One end of the USB communication module 2 is connected to the digital signal processing module 1, and the other end is connected to the USB interface module 3. And the message information between the upper computer and the servo driver is packaged as USB standard communication form or resolved into parallel data, the USB interface module 3 includes the upper computer USB interface 4 and the servo driver USB interface 5 connected by the transmission cable, and with The USB standard communication form transmits the messa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com