Modularized filtering slag-discharging device

A modular filter barrel technology, applied in the direction of filtration separation, filtration circuit, chemical instruments and methods, etc., can solve the problems of difficult maintenance, environmental pollution, waste of resources, high cost, etc., achieve simple circuit configuration, improve slag discharge efficiency, Easy and fast effect to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and a preferred embodiment.

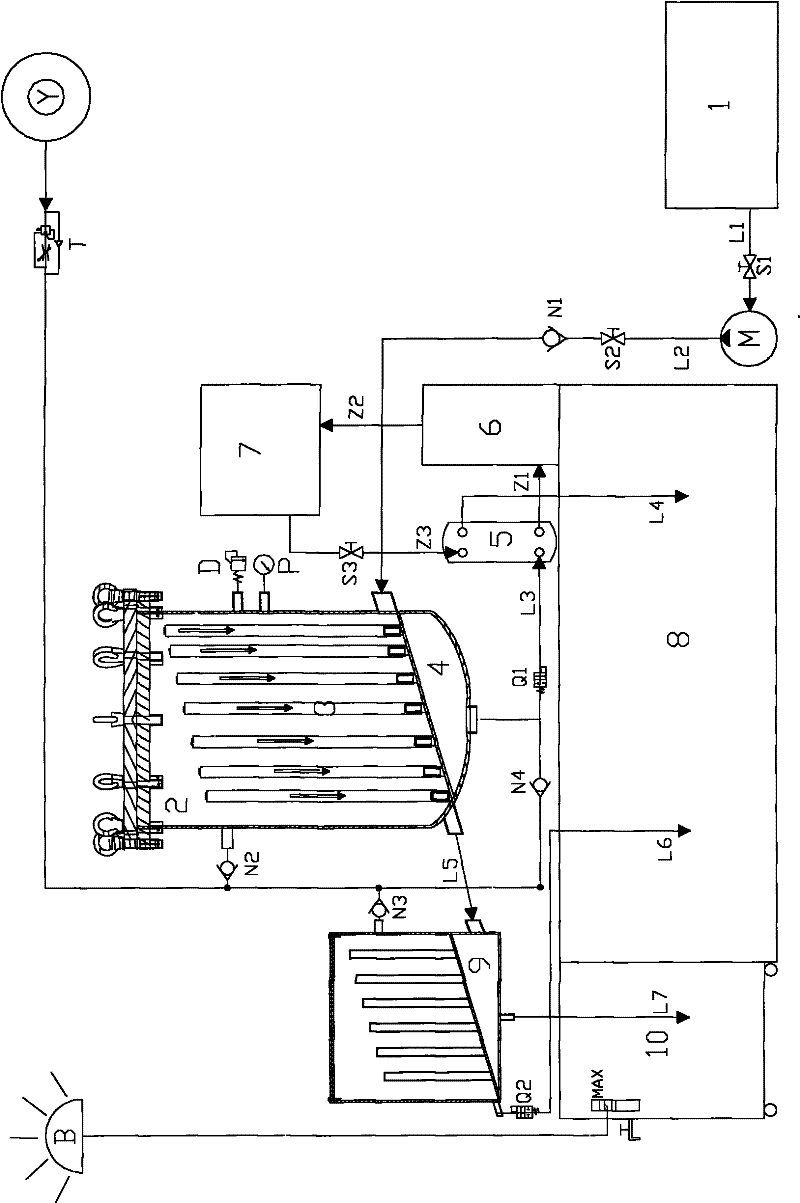

[0024] refer to figure 1 , the modular filter and slag removal system is mainly used to process cutting waste fluid (hereinafter referred to as dirty oil) generated in machining, and it mainly includes an integrated filter barrel 2, a secondary filter device and a refrigeration component. The dirty oil inlet and the clean oil outlet of the aforementioned filter barrel 2 communicate with the dirty oil inlet of the machine platform and the secondary filter device respectively, and its clean oil outlet communicates with the clean oil pool 8 through the refrigeration assembly; the clean oil of the secondary filter device The outlet is communicated with the clean oil pool, and certainly also can be communicated with the clean oil pool through the refrigeration assembly, and its dirt outlet is communicated with the dirt co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap