Intelligent vision capsule identification device

A visual intelligence and recognition device technology, applied in sorting, optical testing flaws/defects, etc., can solve the problems of high labor intensity, low efficiency, poor quality stability, etc., to reduce labor intensity, reduce error rate, imaging good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

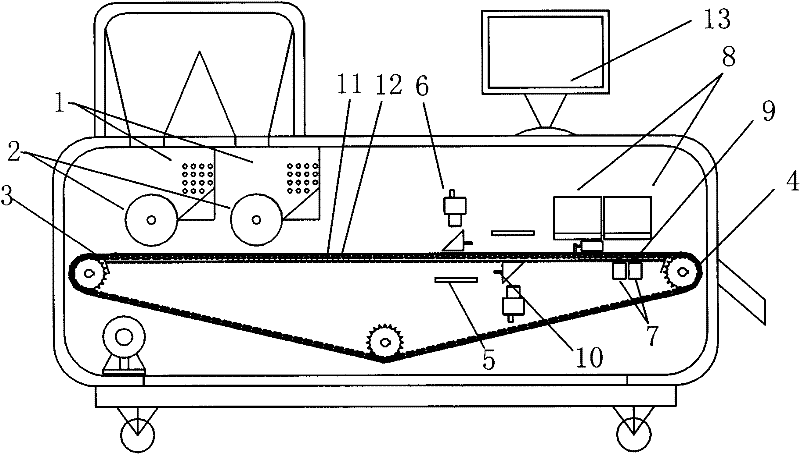

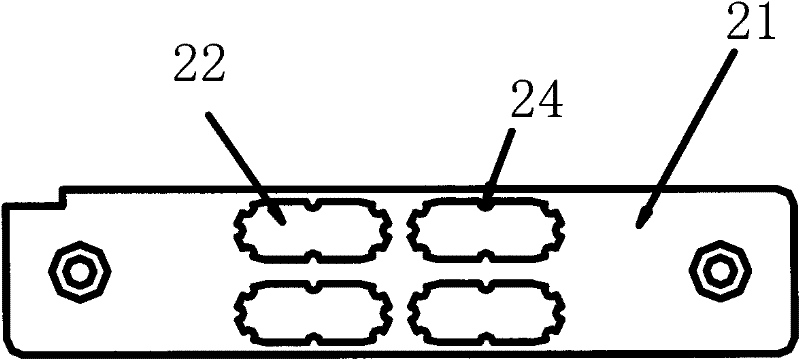

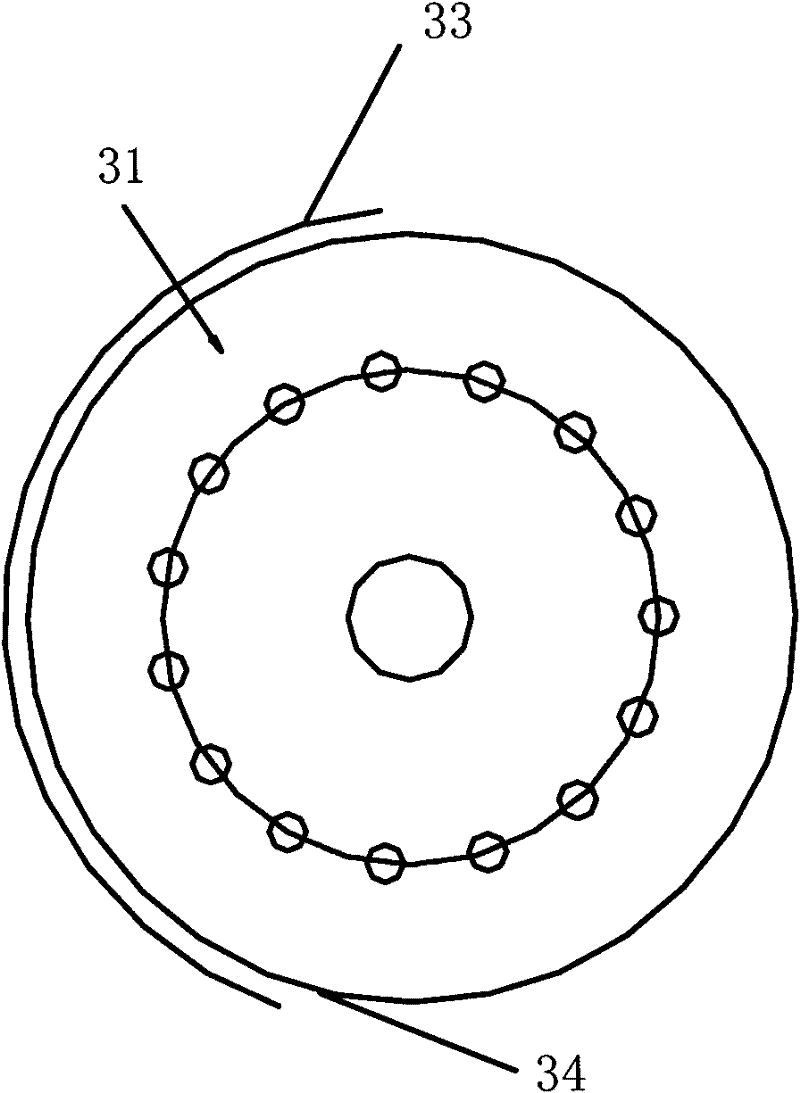

[0027] according to figure 1 The structure shown is a visual intelligent identification capsule device, including an arrangement device 2, a transmission device 3, an identification device 5, a separation device 8, and an intelligent control device 13, and a feeding mechanism 1 with two channels is connected to the upper end of the arrangement device 2 The arrangement device 2 is a round wheel 31, and two rows of L-shaped grooves 32 are distributed on the surface of the round wheel 31, such as Figure 4 As shown in the structure, the length of both sides of the L-shaped groove 32 is equivalent to the length of the capsule, which can ensure that the capsule can be transferred from one side of the groove to the other in the L-shaped groove 32; the feeding mechanism 1 and the surface of the round wheel 31 The position of the L-shaped groove 32 is corresponding; there is an arc-shaped protective screen 33 on the surface of the round wheel 31, such as image 3 The structure shown;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com