Liner of ball sports product and manufacture method thereof as well as ball sports product

A production method and technology for sports goods, which can be applied to balls, sports accessories, hollow objects, etc., can solve the problems of low recycling rate, human allergy injury, odor, etc., and achieve good air tightness, soft touch and comfort, Even thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

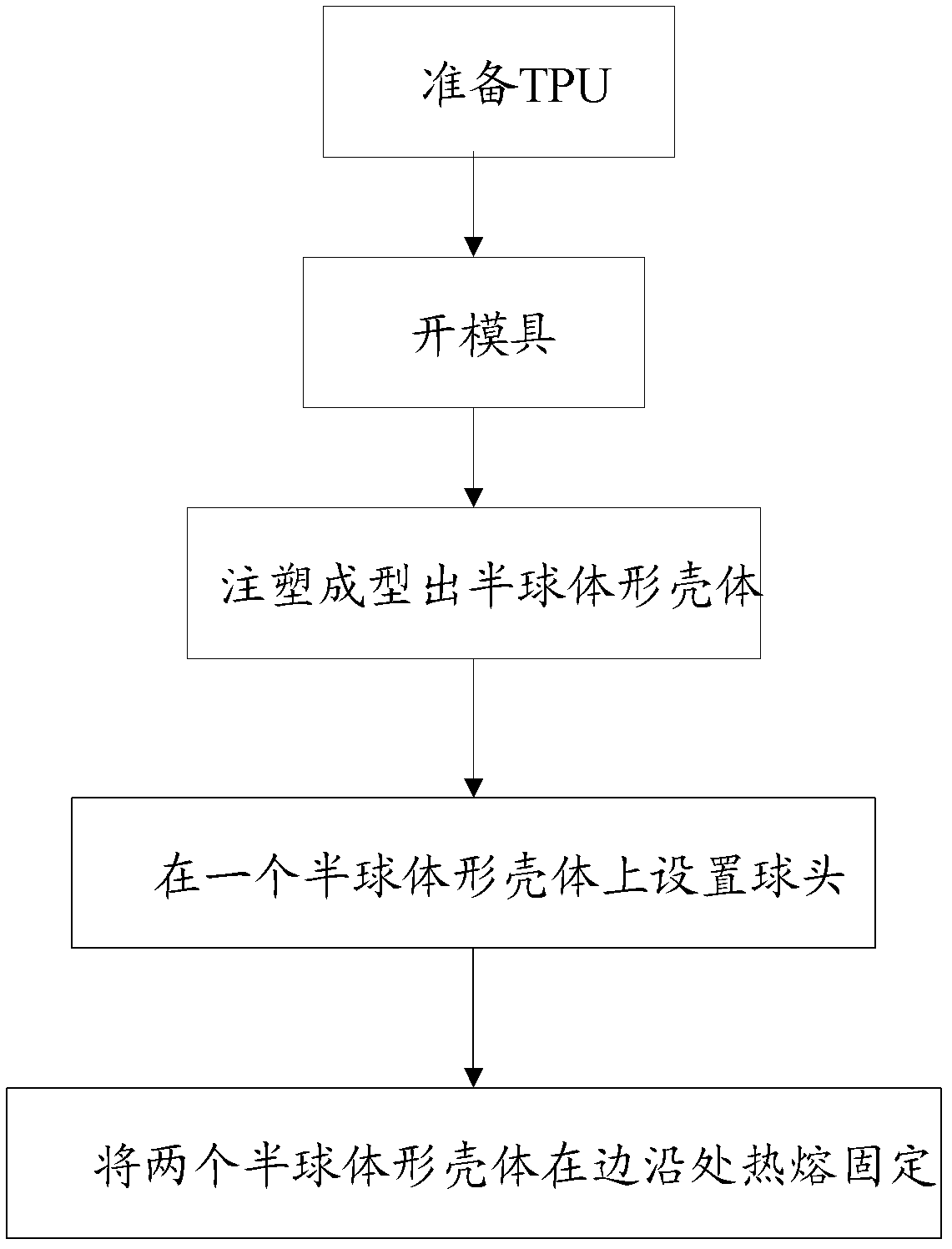

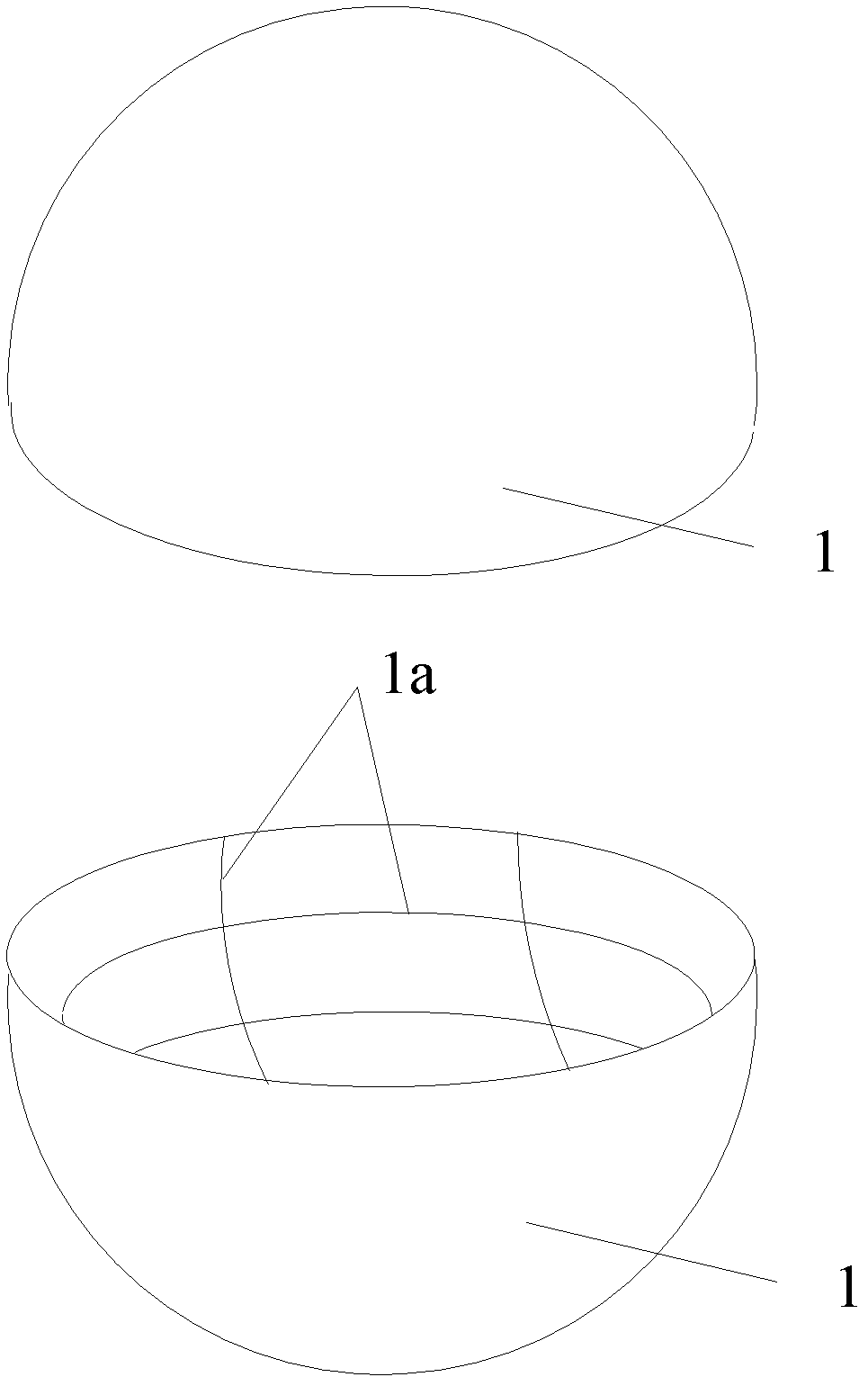

[0071] The liner manufacturing method of this embodiment can refer to the foregoing embodiments, see figure 2 , the skeleton 1a of the liner is set on the inner side of its body-hemispherical shell 1, which is a built-in skeleton, and the impact resistance effect is better.

Embodiment 2

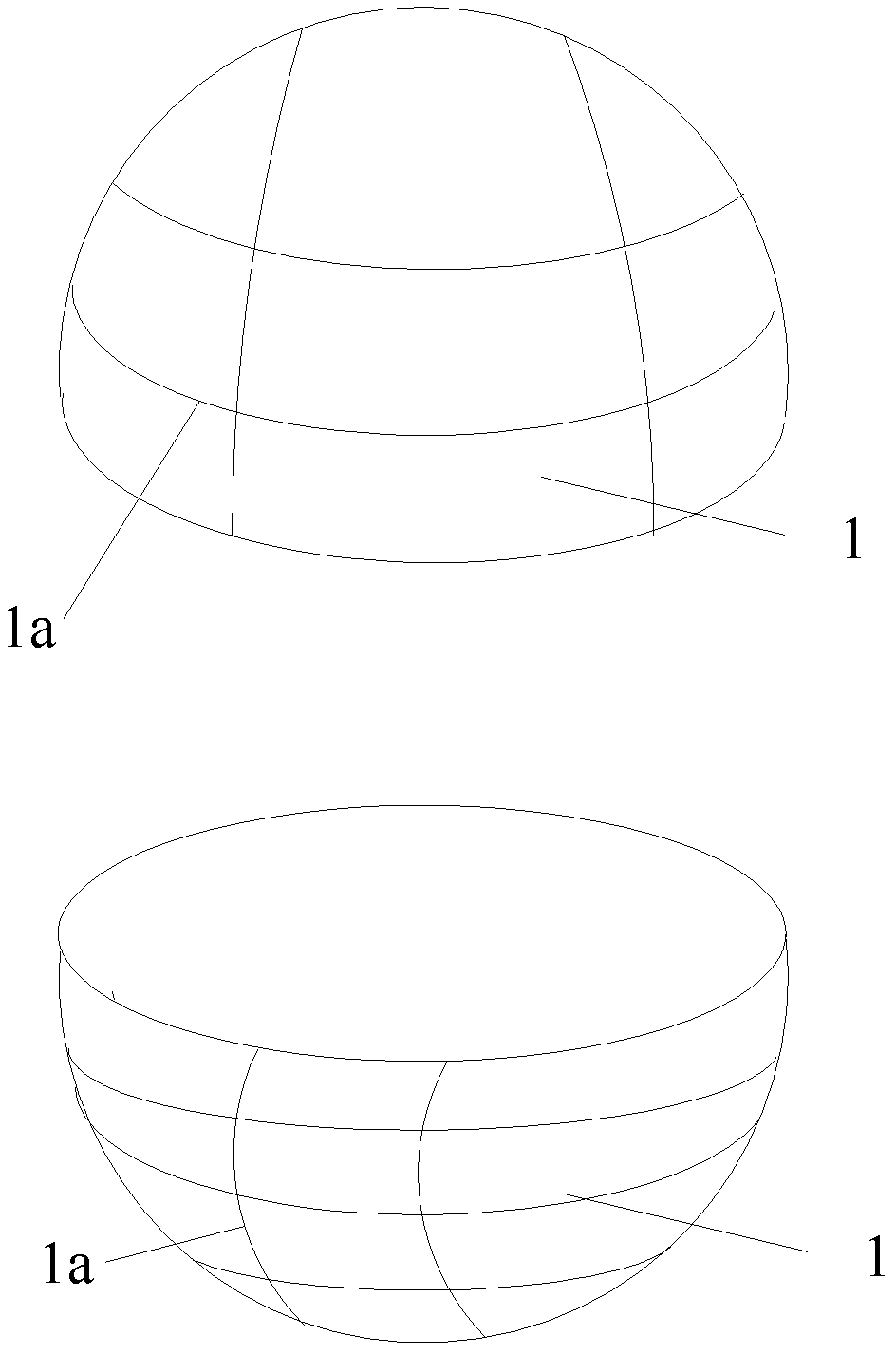

[0073] The liner manufacturing method of this embodiment can refer to the foregoing embodiments, see image 3 , The skeleton 1a of the liner is arranged on the outside of its body-hemispherical shell 1.

Embodiment 3

[0075] see Figure 4 , The difference between this embodiment and Embodiment 1 is that the skeleton 1a of the inner tank is arranged on the inner and outer sides of the body-hemispherical shell 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com