Cement clinker manufacturing device and manufacturing method

A technology for cement clinker and manufacturing equipment, which is applied in the field of cement clinker manufacturing equipment, and can solve problems such as clinker melting and adhesion, coating failure, and reduction of clinker firing heat, so as to achieve the effect of reducing firing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

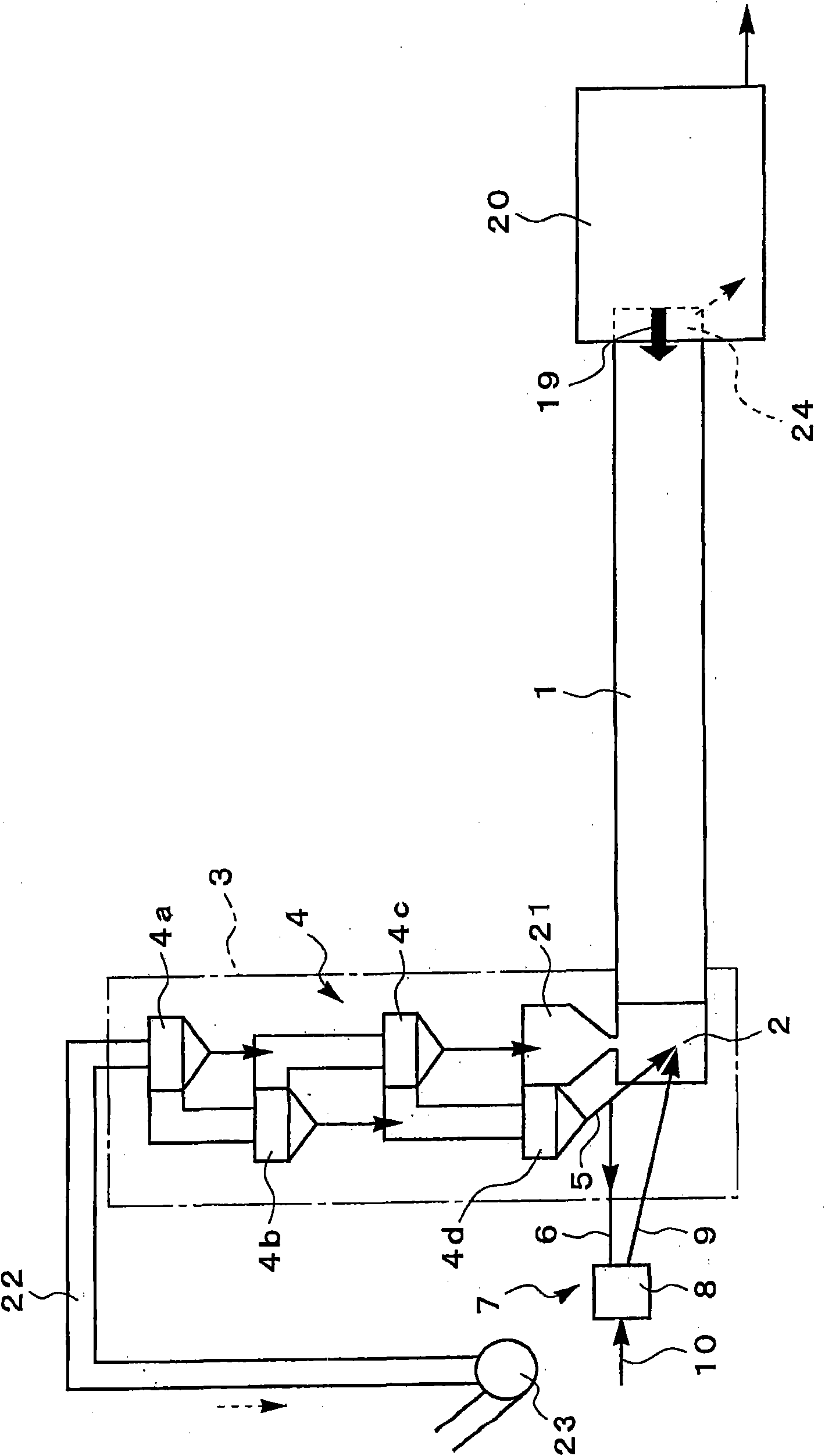

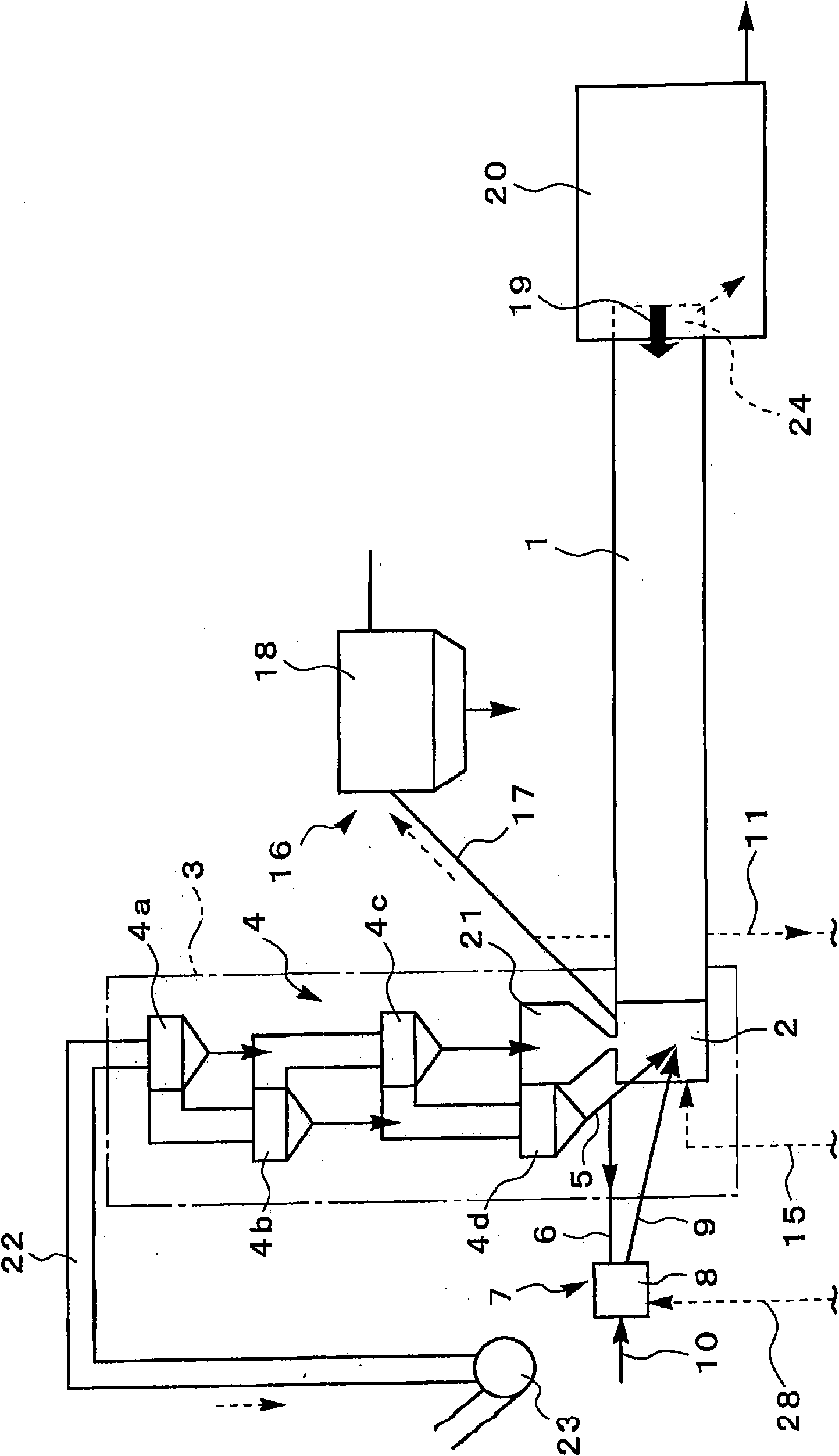

[0057] figure 1 Showing the first embodiment of the manufacturing apparatus of cement clinker of the present invention, figure 2 Indicates its modified example.

[0058] Such as figure 1 As shown, the first embodiment has a rotary kiln 1 for firing cement raw materials, and a preheater 3 for preheating cement raw materials is arranged in series at the kiln tail 2 on the left side of the figure of the rotary kiln 1 , the kiln front 24 on the right side of the figure is used to heat the main burner 19 inside, and the kiln front 24 is used to cool the clinker cooler 20 of the fired cement clinker. The chute 5 of the cyclone separator 4 of the lower section takes out the take-out pipeline 6 of the cement raw material, the firing furnace 8 connected with the take-off pipeline 6, and the above-mentioned cement raw material fired in the firing furnace 8 is returned to the rotary The return pipeline 9 of the kiln tail 2 of the kiln 1 is roughly constituted.

[0059] Among them, t...

Embodiment approach 2

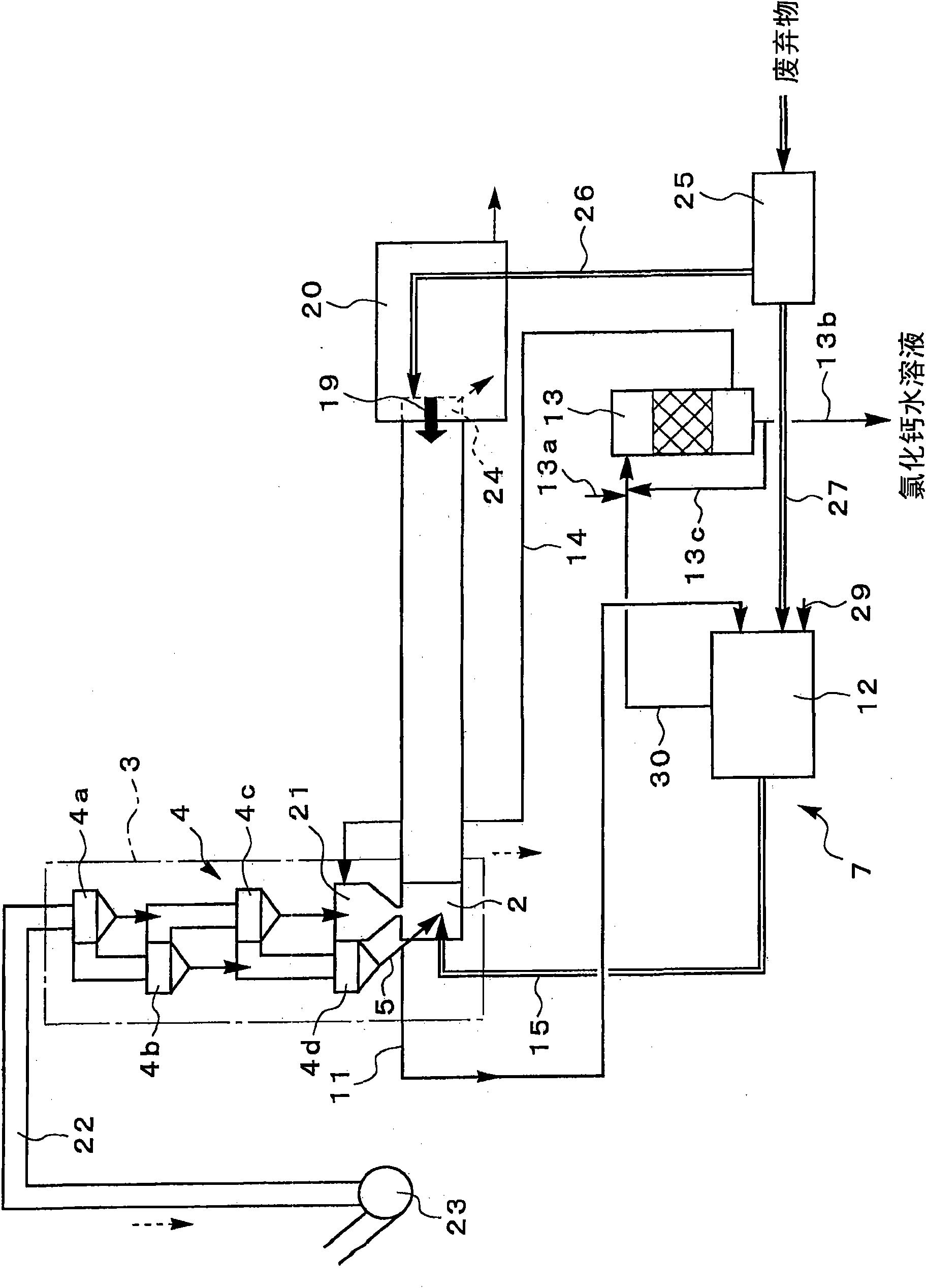

[0074] image 3 Shows the second embodiment of the manufacturing apparatus of cement clinker of the present invention, for the figure 1 The same structural parts shown are similarly attached with the same symbols and their descriptions are simplified.

[0075] Such as image 3 As shown, in the second embodiment, in a cement clinker manufacturing apparatus having a rotary kiln 1, a preheater 3 including a four-stage cyclone separator 4, a calciner 21, etc., as a firing facility 7, a A waste fuelization system for pre-treating chlorine-containing combustible plastic waste and introducing it into the rotary kiln 1.

[0076] The sorting device 25 provided on the most upstream side of the waste fuelization system is installed in the waste fuelization system. The sorting device 25 separates the combustible plastic wastes to be processed into wastes with a high chlorine content such as polyvinyl chloride and polyvinylidene chloride (hereinafter referred to as chlorine-containing p...

Embodiment approach 3

[0101] Figure 4 Shows the third embodiment of the cement clinker manufacturing apparatus of the present invention, for the figure 1 and image 3 The same structural components shown are similarly attached with the same symbols and their explanations are simplified.

[0102] Such as Figure 4 As shown, in the third embodiment, as the firing equipment 7, set figure 1 The kiln 8 of the first embodiment shown is provided with a pyrolysis furnace 12 used in the second embodiment for pretreatment of combustible plastic waste containing chlorine and introducing it into the rotary Waste fuelization system in kiln 1.

[0103] In this third embodiment, the removal line 6 for taking out the cement raw material from the chute 5 of the lower cyclone separator 4d described in the first embodiment and the heat medium supply line 11 described in the second embodiment are connect. Moreover, the thermal decomposition furnace 12 of the above-mentioned waste fuelization system is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com