Heat conducting nanometer material and preparation method and application thereof

A nano-composite material, nano-scale technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment processing, etc., can solve the problems of limited improvement in mechanical properties of composite materials, lack of thermal conductivity of composite materials, and reduction of production costs. , to achieve the effect of improving mechanical properties and thermal conductivity, accelerating the pace of industrialization of in-situ composite technology, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Remove the brown part contained in the natural halloysite, dry it with hot air at 90°C for 10 hours, and then pulverize it; take the pulverized halloysite powder, distilled water and powdered sodium hexametaphosphate at a mass ratio of 1:10:0.002 to prepare solution; stirred at room temperature for 24 hours and then stood still for 72 hours; took the clear solution after standing and stratified and dried it with hot air at 90°C for 24 hours until the halloysite became a block; crushed the block halloysite and passed 200 Mesh sieve to obtain nano-scale pure halloysite powder; nano-scale halloysite powder has a tubular structure, which can be called halloysite nanotubes (HNTs), and HNTs is rich in high thermal conductivity components Al2O3 (Al 2 o 3 ), the mass content of aluminum oxide is as high as 40.4%.

[0037]The raw materials of polyamide 66 and Vectra A 950 (TLCP) were vacuum-dried at 110°C for 10 hours; the halloysite nanotubes (HNTs) prepared above were dried i...

Embodiment 2

[0042] Remove the brown part contained in the natural halloysite, dry it with hot air at 90°C for 10 hours, and then pulverize it; take the pulverized halloysite powder, distilled water and powdered sodium hexametaphosphate at a mass ratio of 1:10:0.5% to prepare into a solution; stirred at room temperature for 24 hours and then stood still for 72 hours; took the clear solution after standing and stratified and dried it with hot air at 90 ° C for 24 hours until the halloysite became a block; crushed the block halloysite, and passed 200 mesh sieve to obtain nano-scale pure halloysite powder;

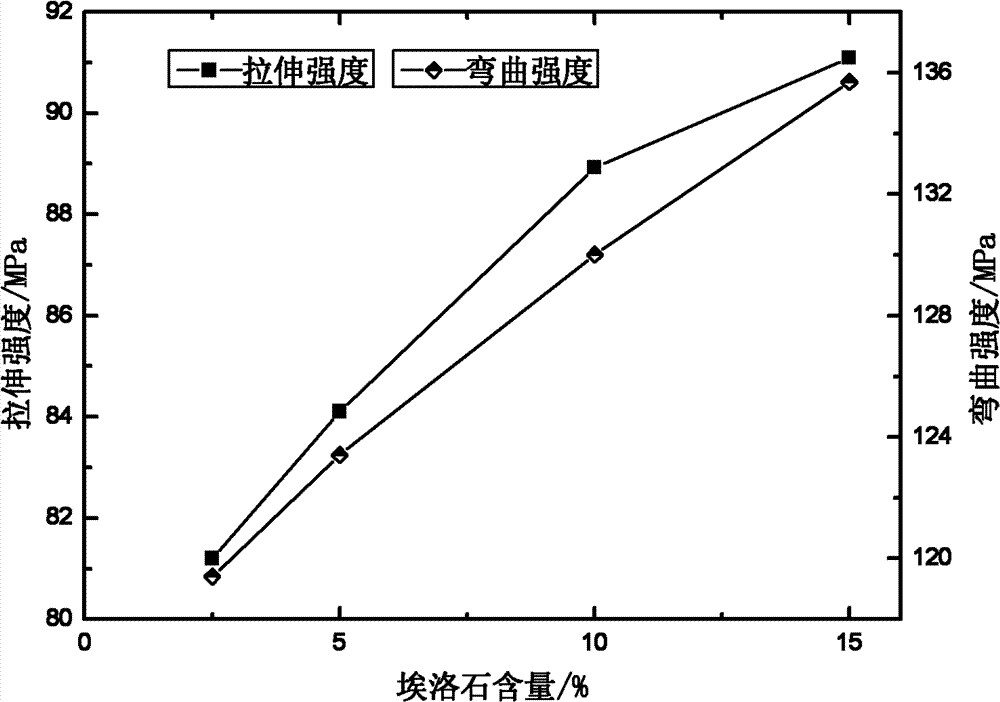

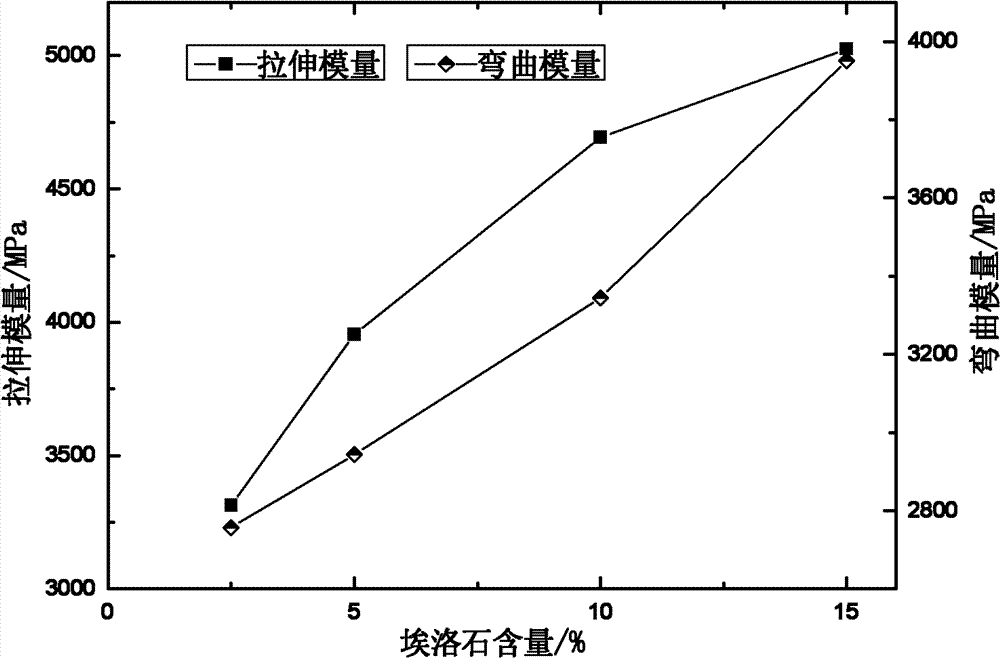

[0043] The polyamide 66 and Vectra A 950 raw materials were vacuum-dried at 110°C for 10 hours; the homemade halloysite nanotubes (HNTs) were vacuum-dried at 100°C for 8 hours; the dried raw materials were prepared according to the following ratio (mass ratio) Preparation of blends: PA66 / TLCP / HNTS were 93.5:4:2.5; 91:4:5; 86:4:10; 81:4:15; the total weight of the blends was 550 grams, and...

Embodiment 3

[0047] Remove the brown part contained in the natural halloysite, dry it with hot air at 90°C for 10 hours, and then pulverize it; take the pulverized halloysite powder, distilled water and powdered sodium hexametaphosphate at a mass ratio of 1:10:1.0% to prepare into a solution; stirred at room temperature for 24 hours and then stood still for 72 hours; took the clear solution after standing and stratified and dried it with hot air at 90 ° C for 24 hours until the halloysite became a block; crushed the block halloysite, and passed 200 mesh sieve to obtain nano-scale pure halloysite powder;

[0048] The polyamide 66 and Vectra A 950 raw materials were vacuum-dried at 110°C for 10 hours; the homemade halloysite nanotubes (HNTs) were vacuum-dried at 100°C for 8 hours; the dried raw materials were prepared according to the following ratio (mass ratio) Preparation of blends: PA66 / TLCP / H NTS are 93.5:4:2.5; 91:4:5; 86:4:10; 81:4:15; the total weight of the blend is 550 grams, after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com