Dehumidifying and cooling system of offshore wind generating set

A technology for wind turbines and cooling systems, applied to wind turbine components, wind engines, wind power generation, etc., which can solve problems such as damage, air insecurity, and limited cooling effects, and achieve reliability and long-term service life. Working environment, the effect of avoiding salt spray corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

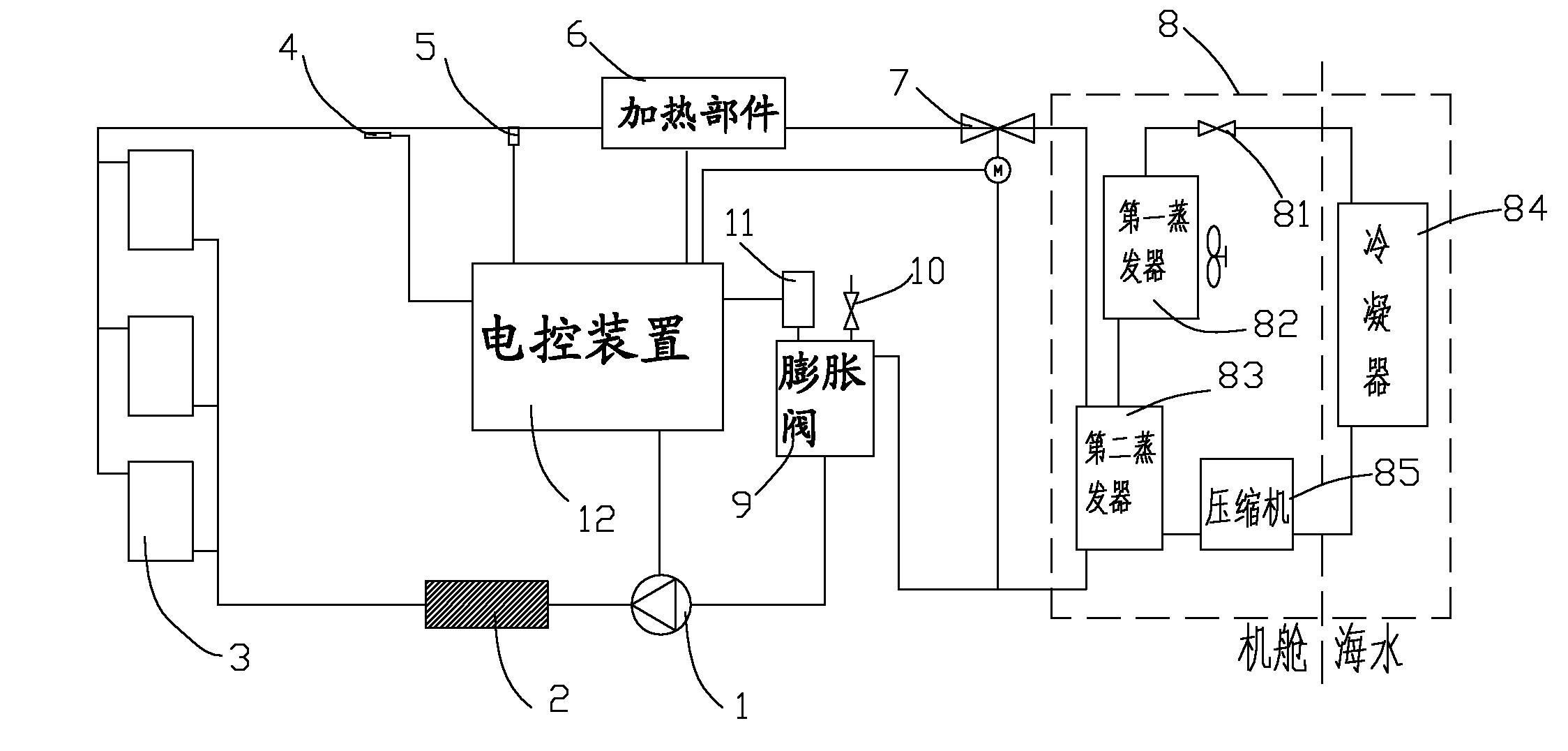

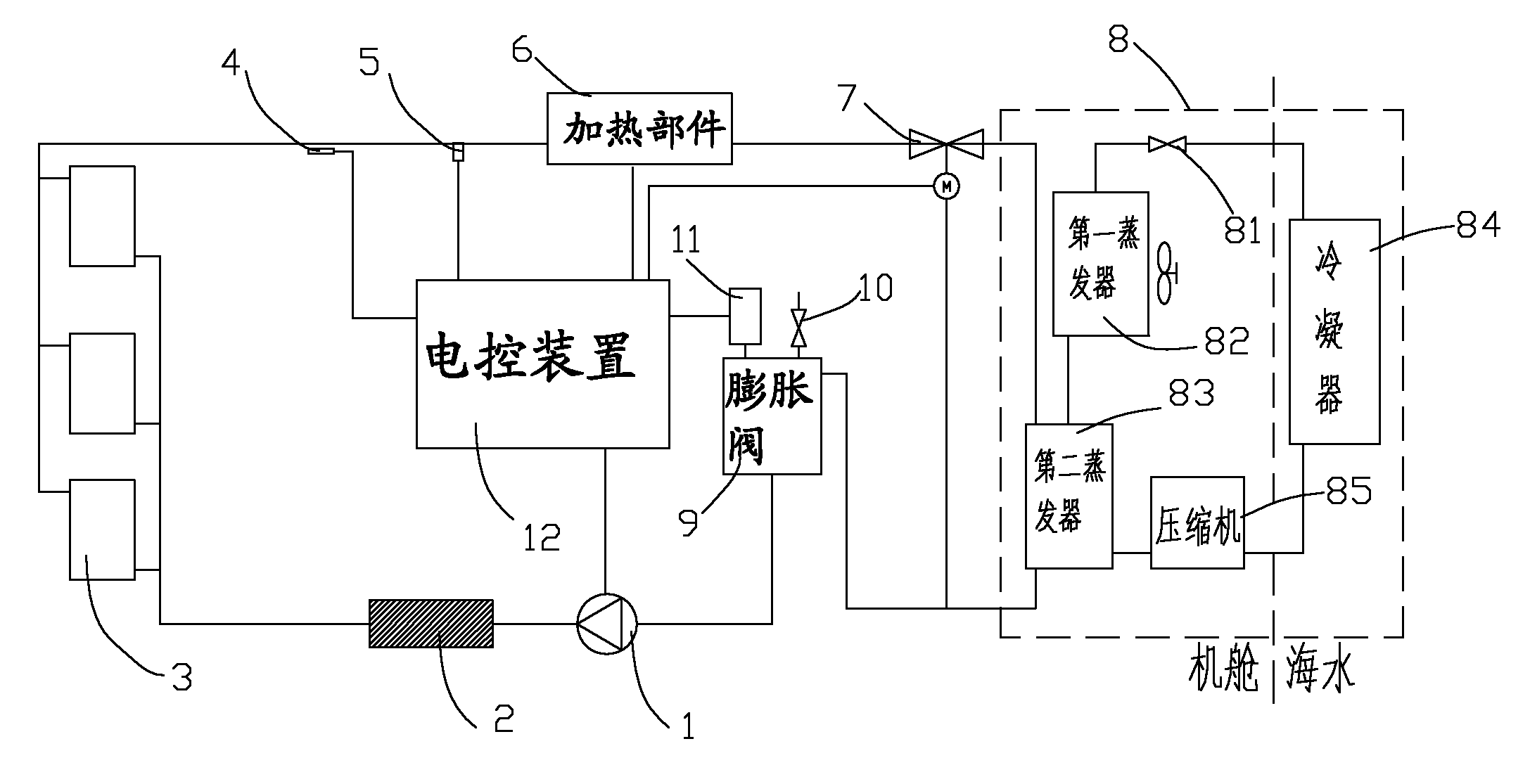

[0040] see figure 1 As shown, the cooling system of the offshore wind power generating set includes a circulation pump 1, a filter device 2, a radiator 3, a heating component 6, a three-way solenoid valve 7, and an expansion tank 9 arranged in the nacelle and connected end to end in order to form a circuit. ; The pipeline connected between the radiator 3 and the heating component 6 is provided with a temperature detection device 4 and a pressure detection device 5 in sequence; it also includes a vapor compression refrigeration unit 8, which includes a throttling element 81 located in the engine room, The first evaporator 82, the second evaporator 83, the compressor 85, and the condenser 84 arranged in the seawater, the throttling element 81, the first evaporator 82, the second evaporator 83, the compressor 85, the condenser 84 They are connected in sequence to form a circuit; both ends of the second evaporator 83 are also connected to the three-way solenoid valve 7 and the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com