Vending system and method for vending machine

A technology for vending machines and goods, applied in the direction of instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc. Body damage and other problems, to achieve the effect of convenient and intensive management, simple structure and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings:

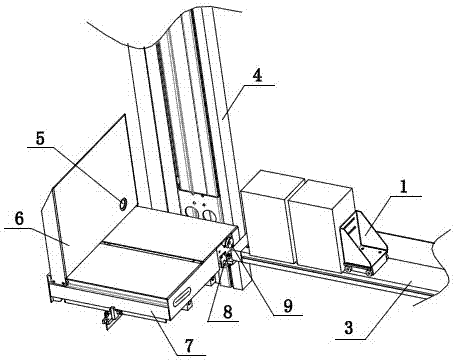

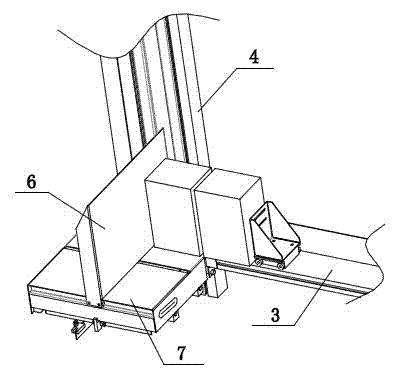

[0027] An automatic vending machine vending system, comprising a cargo supply system, a cargo pickup system, and a delivery system,

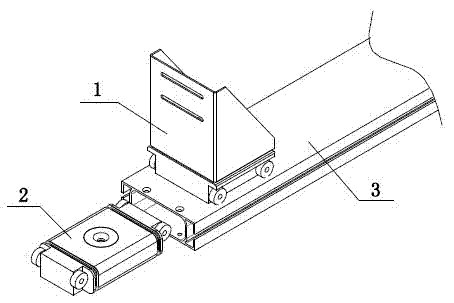

[0028] The described cargo supply system includes a guide rail 3, a piston 2 arranged in the guide rail and a slider 1 arranged on the guide rail, wherein the upper part of the piston 2 and the lower part of the slider 1 are respectively provided with magnetic steel, and the slider 1 acts on the magnetic force of the magnet steel. The lower part moves with the piston 2, the guide rail 3 and the piston 2 form a closed cavity, the end of the guide rail 3 is provided with a small hole, and the movement of the piston is controlled by vacuuming the cavity through the small hole;

[0029] The described picking system adopts the coordinate positioning method, including the horizontal moving rod 4 and the vertical movable platform 7, and the goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com