Lead frame, semiconductor device using the lead frame, intermediate product thereof, and methods for producing same

A manufacturing method and lead frame technology, which are applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as terminal drop-off, reduced adhesion, and inability to maintain terminal strength, so as to improve bonding Strength and reliability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Embodiments for embodying the present invention will be described with reference to the drawings.

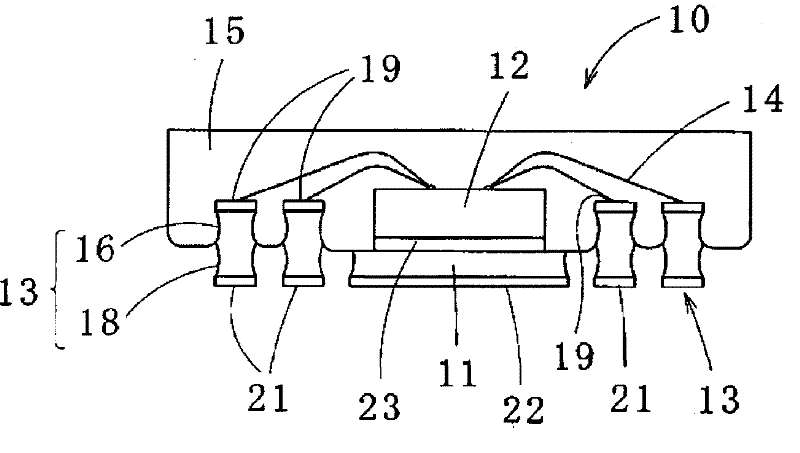

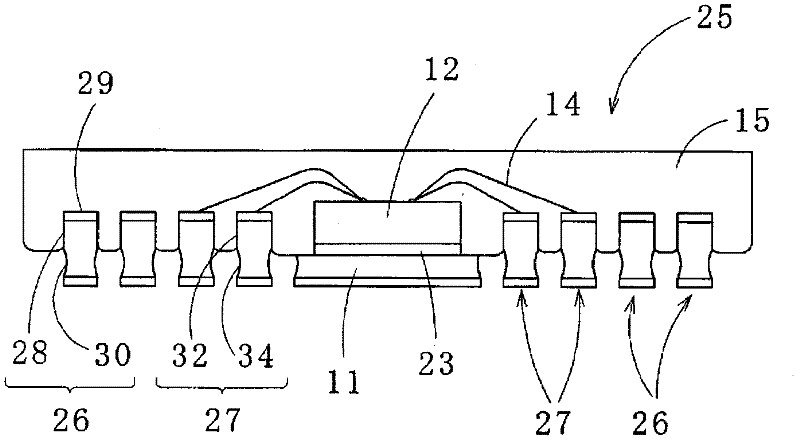

[0064] Such as figure 1 and 2 As shown, the semiconductor device 10 according to the first embodiment of the present invention includes: a semiconductor element 12 placed on a central element mounting portion 11; a plurality of terminals 13 arranged around the semiconductor element 12; and a sealing resin 15 that seals substantially the upper half of the terminal 13, the bonding wire 14, and the semiconductor element 12 with a resin.

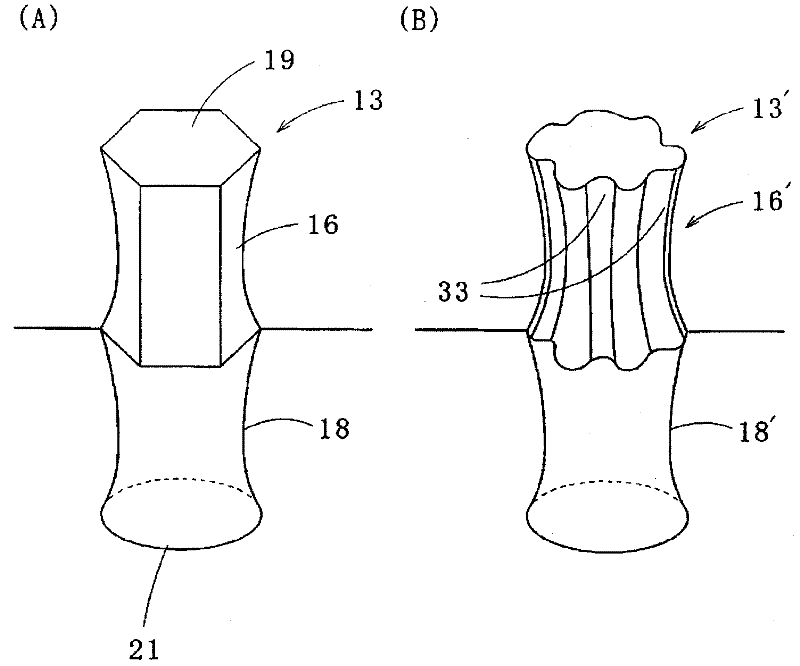

[0065] Here, the shape of the part 16 surrounded by the sealing resin 15 and sealed by the resin of the substantially upper half of the terminal 13 is a hexagonal columnar shape (as an example of a polygonal columnar shape not less than pentagonal), and the substantially lower half of the The exposed portion 18 is cylindrical in shape. In addition, if figure 2 As shown in (A), when the resin-sealed portion 16 is formed by etching, its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com