Engine-driven cascade heat pump device

An engine-driven, heat pump device technology, used in superheaters, refrigerators, compressors, etc., can solve the problems of complex system, high initial investment, easy failure, etc. The effect of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

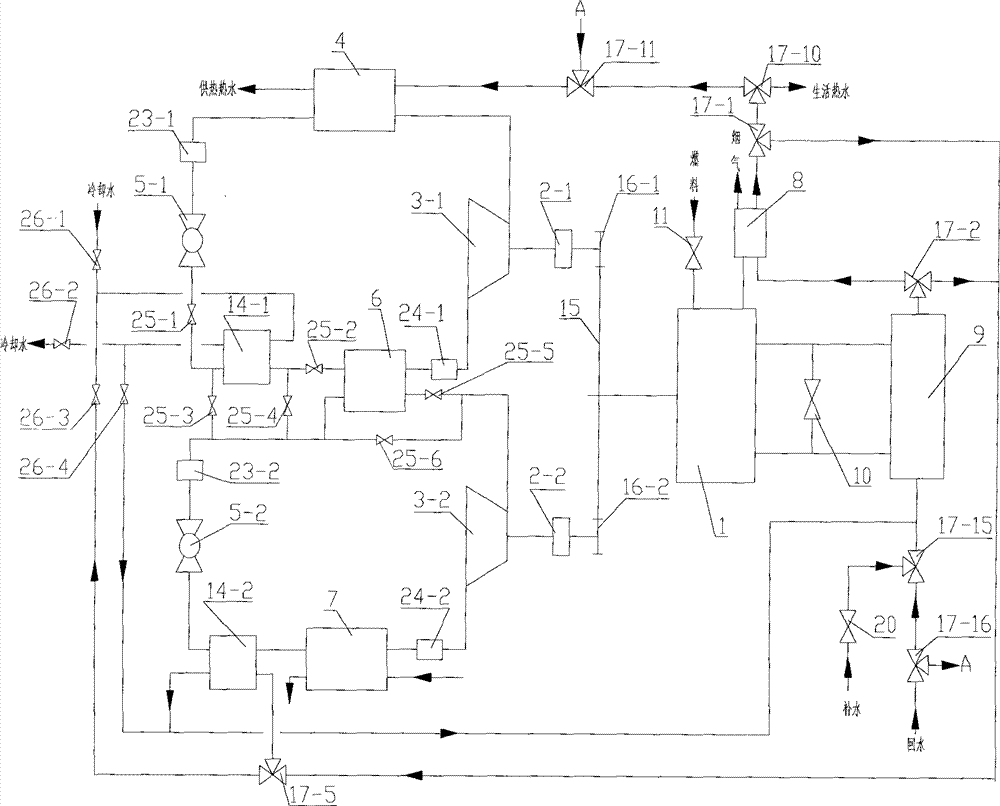

Embodiment 1

[0023] Embodiment 1: as Figure 1a As shown, a binary cascade heat pump device in which one engine drives two compressors consists of three parts: a binary cascade heat pump system, an engine system and a water circuit. As shown in 1a, a binary cascade heat pump system in which one engine drives two compressors includes a high-temperature stage circulation system and a low-temperature stage circulation system. High temperature stage compressor 3-1, condenser 4, high temperature stage liquid receiver 23-1, high temperature stage throttle valve 5-1, high temperature stage refrigerant heater 14-1, condensation evaporator 6, high temperature stage gas-liquid separation 24-1, the first refrigerant side valve 25-1, and the second refrigerant side valve 25-2 form a high-temperature stage refrigerant circulation system, the high-temperature stage compressor 3-1 is connected to the condenser 4, and the condenser 4 is connected to the high-temperature stage The liquid storage device 23-...

Embodiment 2

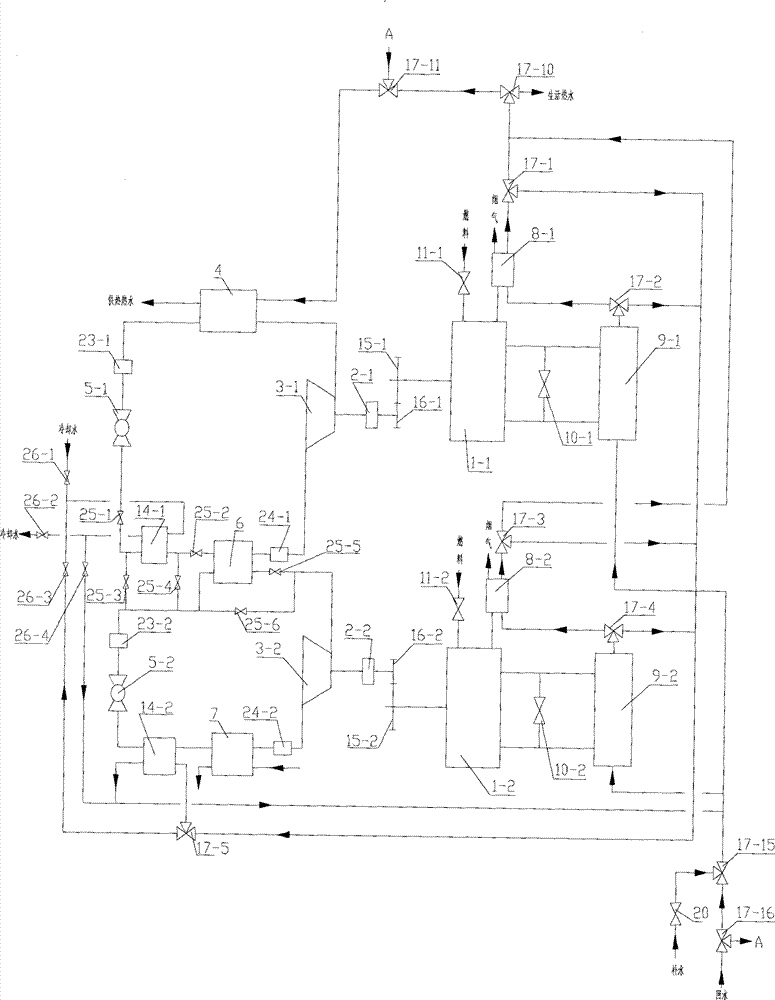

[0026] Embodiment 2: as Figure 1bAs shown, the binary cascade heat pump device with two engines driving two compressors consists of three parts: the binary cascade heat pump system, the engine system and the water circuit. The binary cascade heat pump system and its refrigeration and heating operation principles are basically the same as those in Embodiment 1, the difference is that the two compressors 3-1 and 3-2 of the system are respectively driven by two engines 1-1 and 1-2 . The engine system consists of engines 1-1, 1-2, engine cooling heat exchangers 9-1, 9-2, flue gas heat exchangers 8-1, 8-2, cooling water bypass valves 10-1, 10-2 , Composed of fuel regulating valves 11-1 and 11-2. The engine 1-1 is connected to the engine cooling heat exchanger 9-1, a cooling water bypass valve 10-1 is provided between the engine 1-1 and the engine cooling heat exchanger 9-1, and the engine cooling heat exchanger 9-1 is connected to the smoke The gas heat exchanger 8-1 and the fl...

Embodiment 3

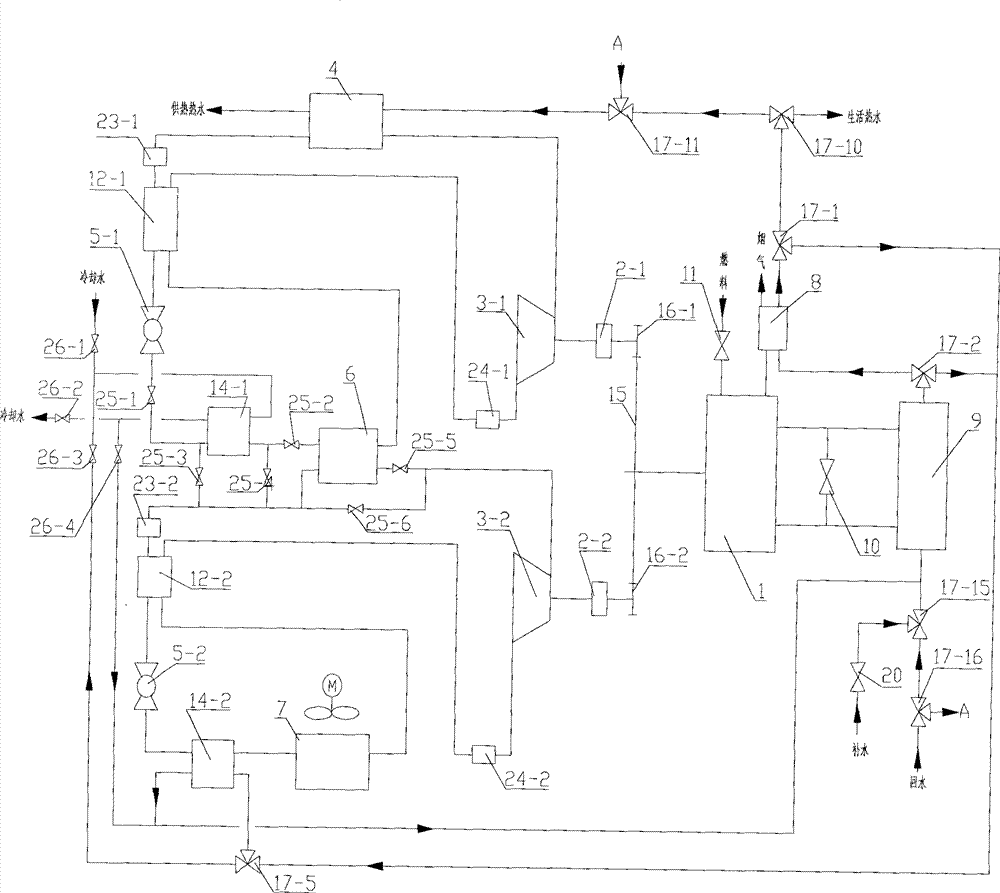

[0027] Embodiment 3: as Figure 2a As shown, it is basically the same as Embodiment 1, the difference is that the high and low temperature recuperation heat exchangers 12-1 and 12-2 are added in the binary cascade heat pump system. The high-temperature stage liquid receiver 23-1 and the high-temperature stage throttle valve 5-1 and the high-temperature stage gas-liquid separator 24-1 and the condensing evaporator 6 are connected with a high-temperature stage regenerative heat exchanger 12-1, and a low-temperature stage The low-temperature stage recuperation heat exchanger 12-2 is connected between the liquid reservoir 23-2 and the low-temperature stage throttle valve 5-2 and between the low-temperature stage gas-liquid separator 24-2 and the evaporator 7; cold evaporator.

[0028] When the system is in refrigeration operation, the high-temperature compressor does not operate, the clutch 2-1 is disconnected, the high-temperature refrigerant heater 14-1 is used as a condenser, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com