Method for preparing tin-carbon composite material for cathode of lithium ion battery

A lithium-ion battery and composite material technology, which is applied in the field of lithium-ion battery negative electrode materials and the preparation thereof, can solve the problems of unreported cycle capacity, unfavorable large-scale production, expensive synthetic raw materials, etc., and achieves high volumetric energy density and saving The effect of energy, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) with fructose (C 6 h 12 o 6 ) and stannous chloride dihydrate (SnCl 2 .2H 2 O) as the initial raw material, 13.3g of fructose was dissolved in 20mL of water, and 10.0g of SnCl was added to the solution 2 .2H 2 O, stir mechanically to obtain a colorless or light yellow transparent mixed solution, heat while stirring, and raise the temperature to 80°C until the water is evaporated to dryness, then dry at 130°C for 2h to obtain the mixture;

[0033] 2) In a flowing high-purity argon atmosphere, raise the temperature of the obtained mixture to 200°C at 5°C / min and keep it warm for 2 hours, then raise the temperature to 400°C at 2°C / min, and cool down to 100°C at 5°C / min, Then wait for it to cool down to room temperature naturally, and the obtained product is the tin-carbon composite material for lithium-ion battery negative electrode.

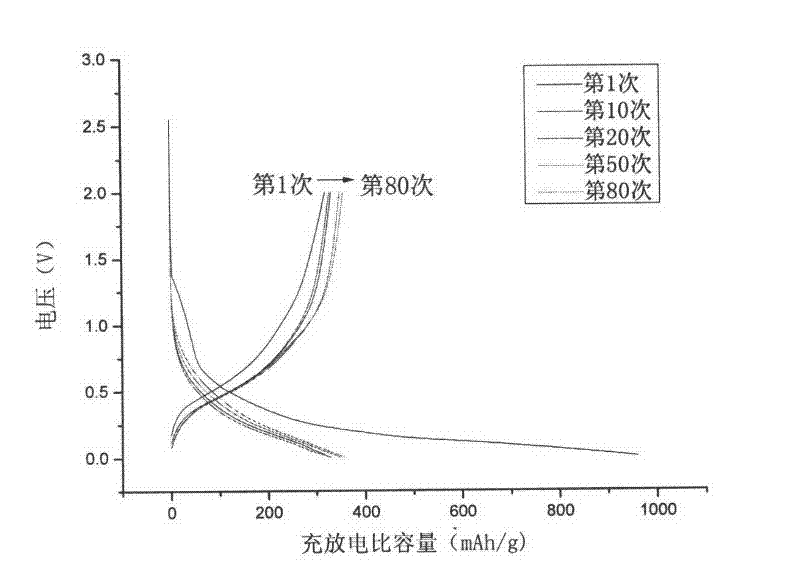

[0034] Mix the above-mentioned tin-carbon composite material for lithium-ion battery negative electrode with 10wt% conductive agen...

Embodiment 2

[0036] 1) with fructose and (SnCl 2 .2H 2 O) is the initial raw material, 10.0g fructose is mixed with the solution of 5.56mol / L, adds 10.0g SnCl in the solution 2 .2H 2 O, stir mechanically to obtain a colorless or light yellow transparent mixed solution, heat while stirring, and raise the temperature to 80°C until the water is evaporated to dryness, then dry at 130°C for 2h to obtain the mixture;

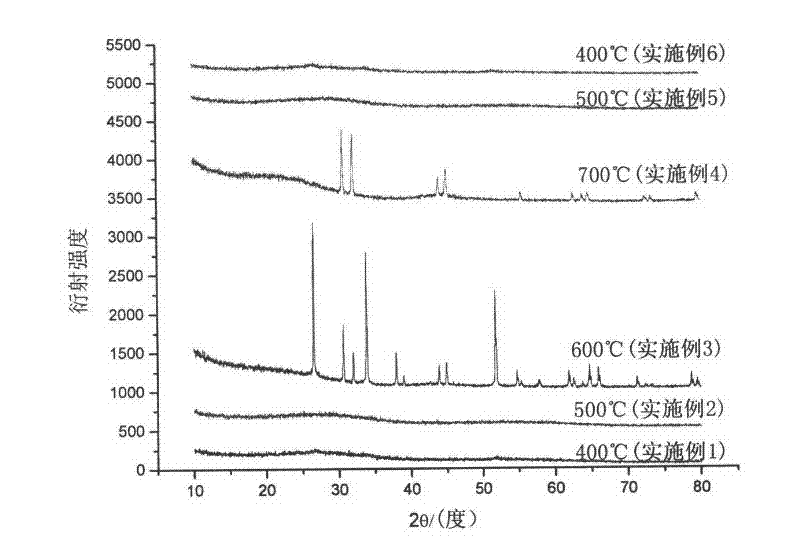

[0037] 2) In a flowing high-purity argon atmosphere, raise the temperature of the obtained mixture to 200°C at 5°C / min and keep it for 2h, then raise the temperature to 500°C at the same rate and keep it for 2h, then cool it down at 5°C / min to 100°C, and then naturally cooled to room temperature, the resulting product is the tin-carbon composite material for the negative electrode of lithium-ion batteries. Its XRD pattern is as follows figure 1 as shown, Figure 7 Its transmission electron microscope picture.

[0038] The material was tested using the same method and condit...

Embodiment 3

[0040] 1) with fructose and SnCl 2 .2H 2 O is the initial raw material, 10.0g fructose is formulated into a 5.56mol / L solution, and 10.0g SnCl is added to the solution 2 .2H 2 O, stir mechanically to obtain a colorless or light yellow transparent mixed solution, heat while stirring, and raise the temperature to 90°C until the water is evaporated to dryness, then dry at 130°C for 2h to obtain the mixture;

[0041] 2) In a flowing high-purity argon atmosphere, raise the temperature of the obtained mixture to 170°C at 5°C / min and keep it for 2h, then raise the temperature to 230°C at 2°C / min and keep it for 2h, and then heat it at 2°C / min Raise the temperature to 600°C and keep it warm for 2 hours, then cool it down to 100°C at 5°C / min, and then let it cool down to room temperature naturally. The resulting product is the tin-carbon composite material for the negative electrode of lithium-ion batteries.

[0042] The same method and conditions as in Example 1 were used to test t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com